Device for processing silicon wafer in electronic device

A technology for processing devices and silicon wafers, applied to fine working devices, working accessories, stone processing equipment, etc., can solve problems such as manual feeding, low degree of automation, and messy silicon wafer output, and achieve inspection and easy use , to achieve the effect of thickness and diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

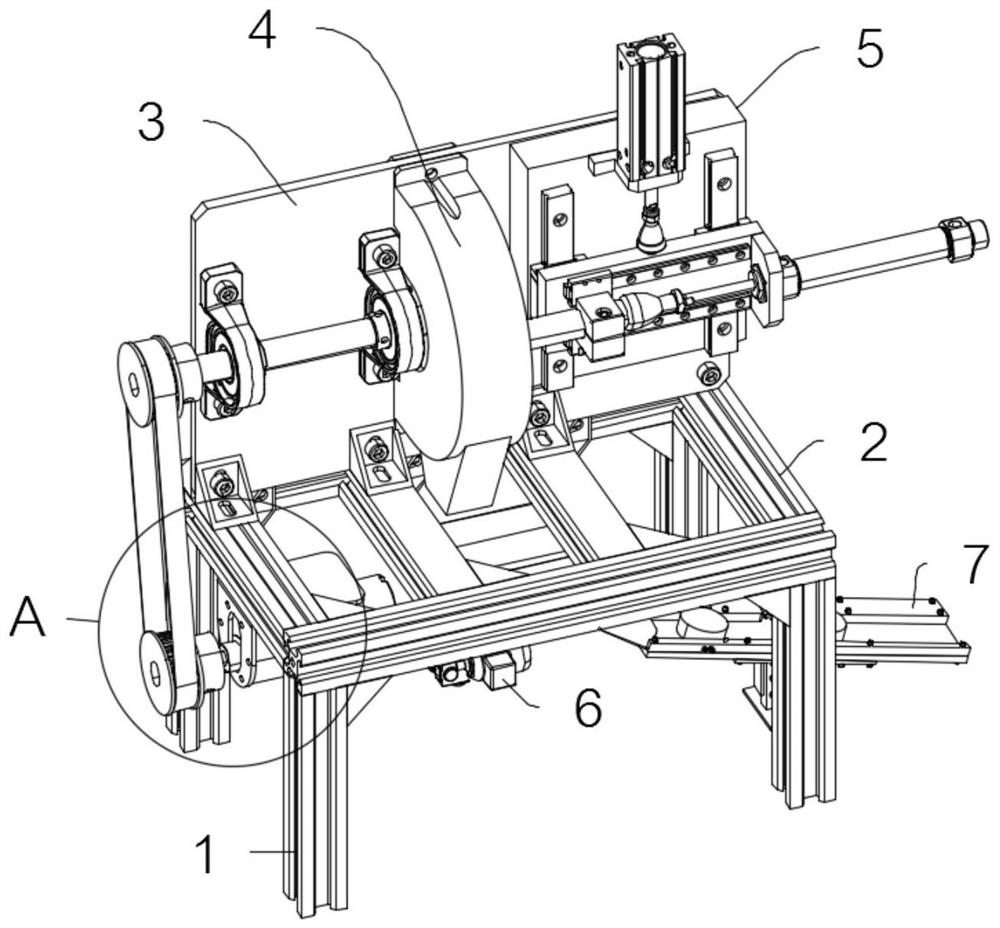

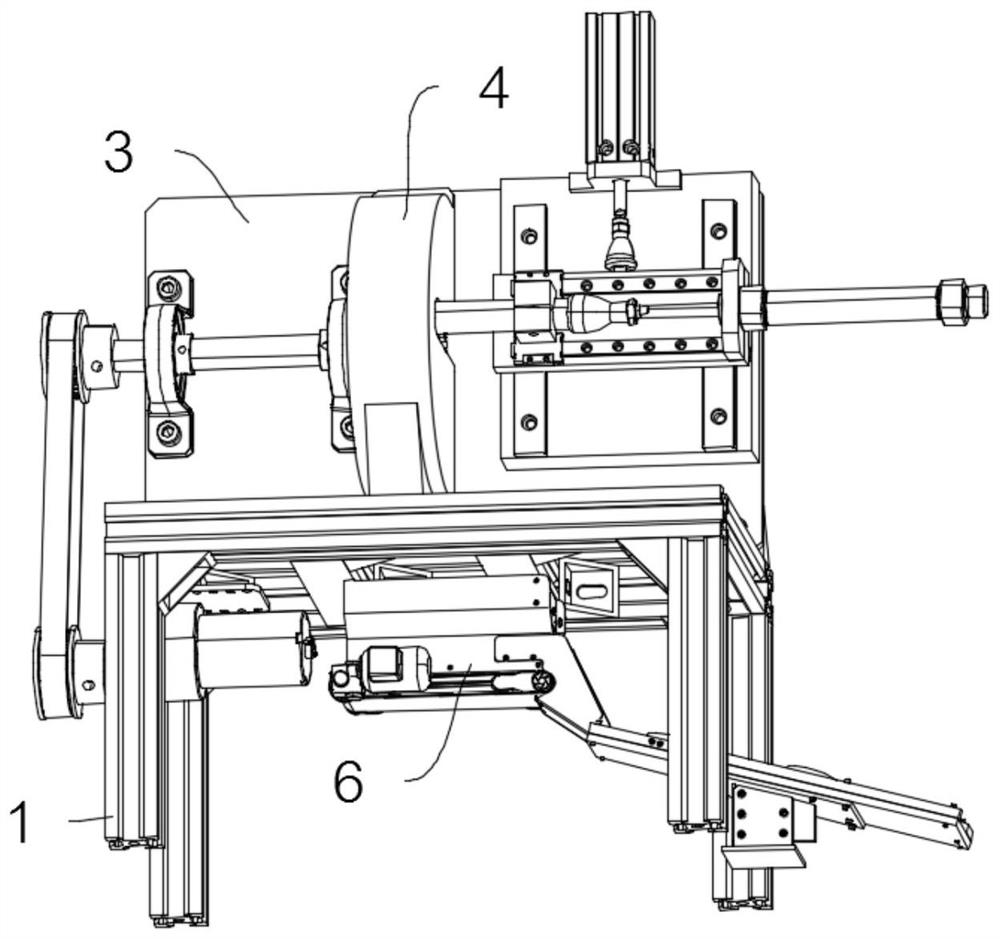

[0059] Example: Please refer to Figure 1 to Figure 10 :

[0060] The present invention proposes a silicon wafer processing device inside an electronic device, comprising: a support column 1;

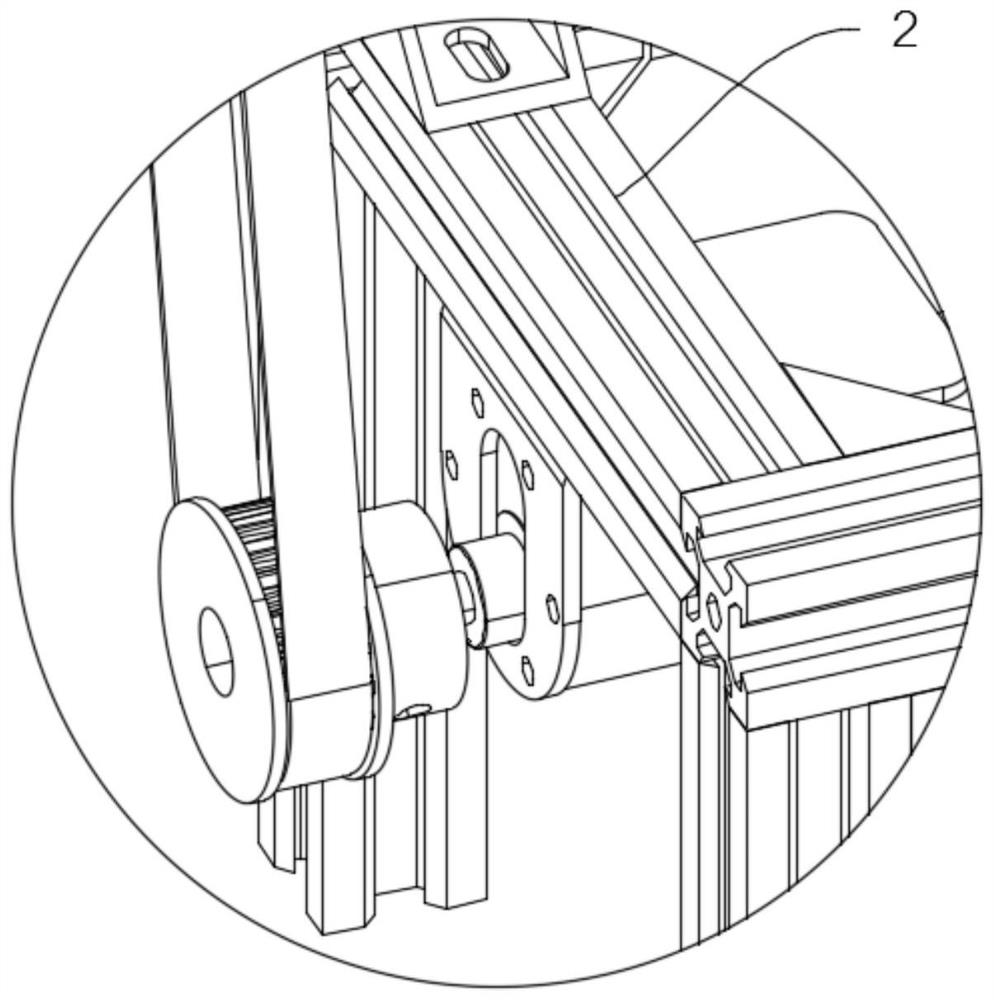

[0061] The support column 1 is provided with four groups, and the lower end of the support column 1 is installed on the ground; the support 2, the support 2 is installed on the upper end of the support column 1, and the support 2 is equipped with a fixed seat, and a motor is installed on the fixed seat, and the rotating shaft of the motor Pulleys are installed on the top; fixed plate 3, the lower end of the fixed plate 3 is equipped with a connecting seat, the lower end of the connecting seat is installed on the bracket 2, two sets of bearing seats are installed on the fixed plate 3, and a through groove is provided on the fixed plate 3 Structure; cutting part 4, the cutting part 4 is installed on the fixed plate 3; feeding part 5, the feeding part 5 is installed on the fixed plate 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com