Pillow inner made of sleep-aiding fragrance type foaming latex

A technology of pillow core and fragrance type, which is applied in the field of pillow core production of sleep-aiding aromatherapy foam latex, can solve the problems of poor comfort and air permeability, and single function, so as to promote sleep quality and enhance sleep Good results in quality, resilience and comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

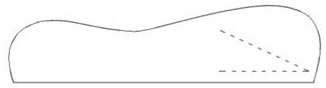

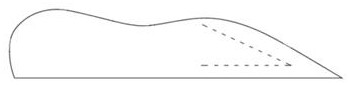

Image

Examples

Embodiment 1

[0047] Embodiment 1, a pillow core for making sleep-promoting aromatherapy foam latex, each component is counted as follows according to its mass percentage: glue juice: 97%, sodium hydroxide solution: 1%, additives: 1%, Sleep aid aromatherapy aids: 1%.

[0048] Material Glue sodium hydroxide solution Add additives Sleep Aid Aromatherapy Auxiliary percentage 97% 1% 1% 1%

[0049] A preparation method for making a pillow core of sleep-aiding aromatherapy foam latex, comprising the following steps:

[0050] The production process of the pillow core includes the following steps:

[0051] S1. According to the design standard, weigh the glue juice and sodium hydroxide solution, pour the weighed glue juice and sodium hydroxide solution into the stirring tank for heating and stirring treatment, the stirring time in the heating and stirring treatment is 20min, The stirring speed is 100r / min, and the ammonia in the glue juice is removed, so that the pH ...

Embodiment 2

[0063] Embodiment 2, a pillow core for making sleep-promoting aromatherapy foam latex, each component is counted as follows according to its mass percentage: glue juice: 92%, sodium hydroxide solution: 2%, additives: 2%, Sleep aid aromatherapy aids: 4%.

[0064] Material Glue sodium hydroxide solution Add additives Sleep Aid Aromatherapy Auxiliary percentage 92% 2% 2% 4%

[0065] A preparation method for making a pillow core of sleep-aiding aromatherapy foam latex, comprising the following steps:

[0066] The production process of the pillow core includes the following steps:

[0067] S1. According to the design standard, weigh the glue juice and sodium hydroxide solution, pour the weighed glue juice and sodium hydroxide solution into the stirring tank for heating and stirring treatment, and the stirring time in the heating and stirring treatment is 50min. The stirring speed is 250r / min, and the ammonia in the glue juice is removed, so that the...

Embodiment 3

[0079] Embodiment 3, a pillow core for making sleep-promoting aromatherapy foam latex, each component is counted as follows according to its mass percentage: glue juice: 94%, sodium hydroxide solution: 1%, additives: 1%, Sleep aid aromatherapy aids: 4%.

[0080] Material Glue sodium hydroxide solution Add additives Sleep Aid Aromatherapy Auxiliary percentage 94% 1% 1% 4%

[0081] A preparation method for making a pillow core of sleep-aiding aromatherapy foam latex, comprising the following steps:

[0082] The production process of the pillow core includes the following steps:

[0083] S1. According to the design standard, weigh the glue juice and sodium hydroxide solution, pour the weighed glue juice and sodium hydroxide solution into the stirring tank for heating and stirring treatment, and the stirring time in the heating and stirring treatment is 30min. The stirring speed is 200r / min, and the ammonia in the glue juice is removed, so that the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com