Hot alkali activated mineral powder crystal nucleus early strength agent as well as preparation method and application thereof

A technology of early strength agent and mineral powder, which is applied in the field of hot alkali excited mineral powder crystal nucleus early strength agent and preparation field, can solve the problems of high preparation cost and long preparation time of calcium silicate crystal nucleus, and achieves the promotion of generation and preparation process. Simple, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

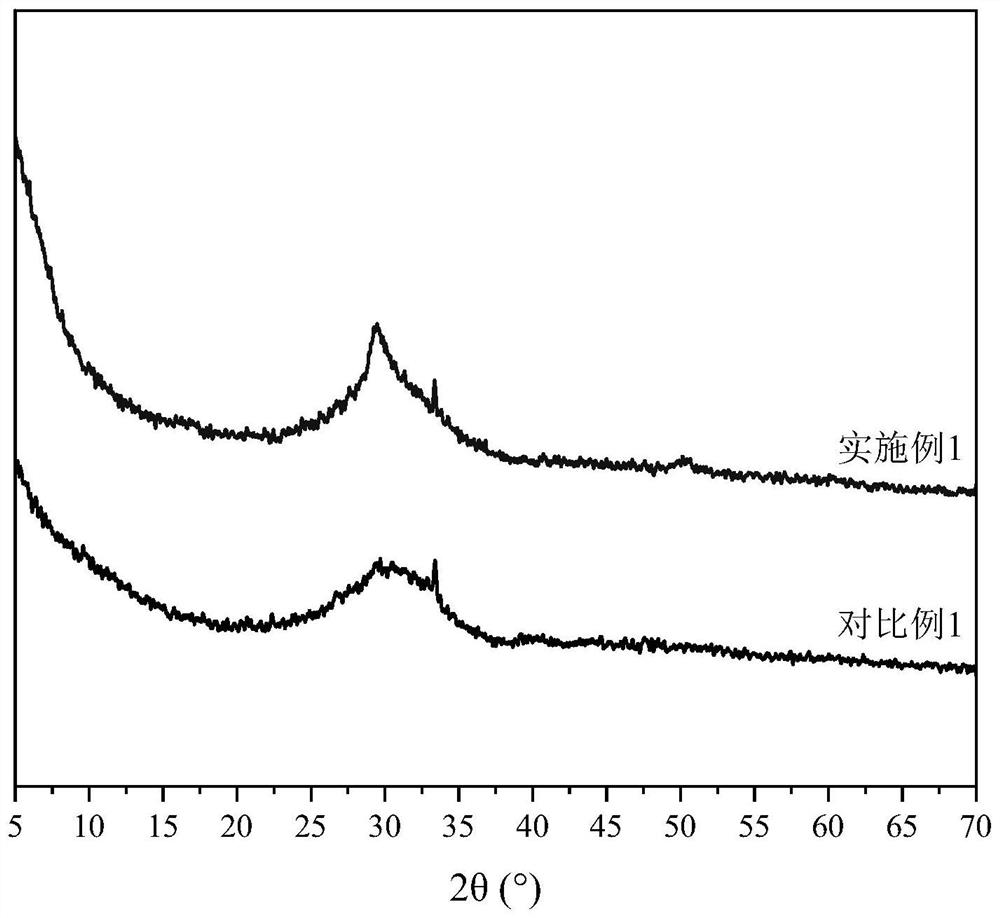

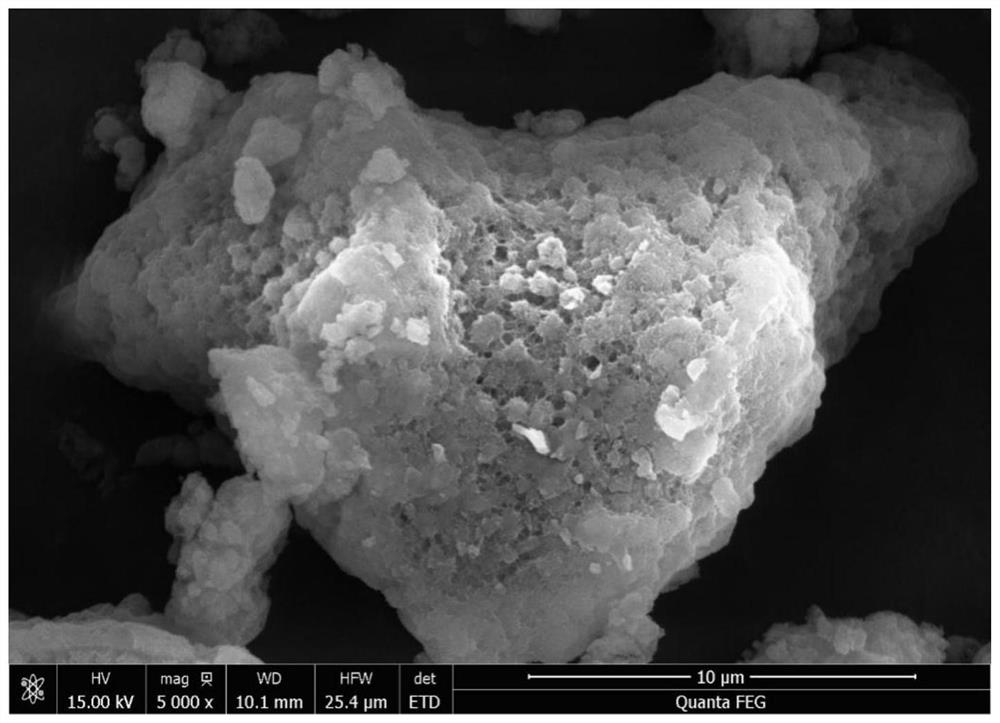

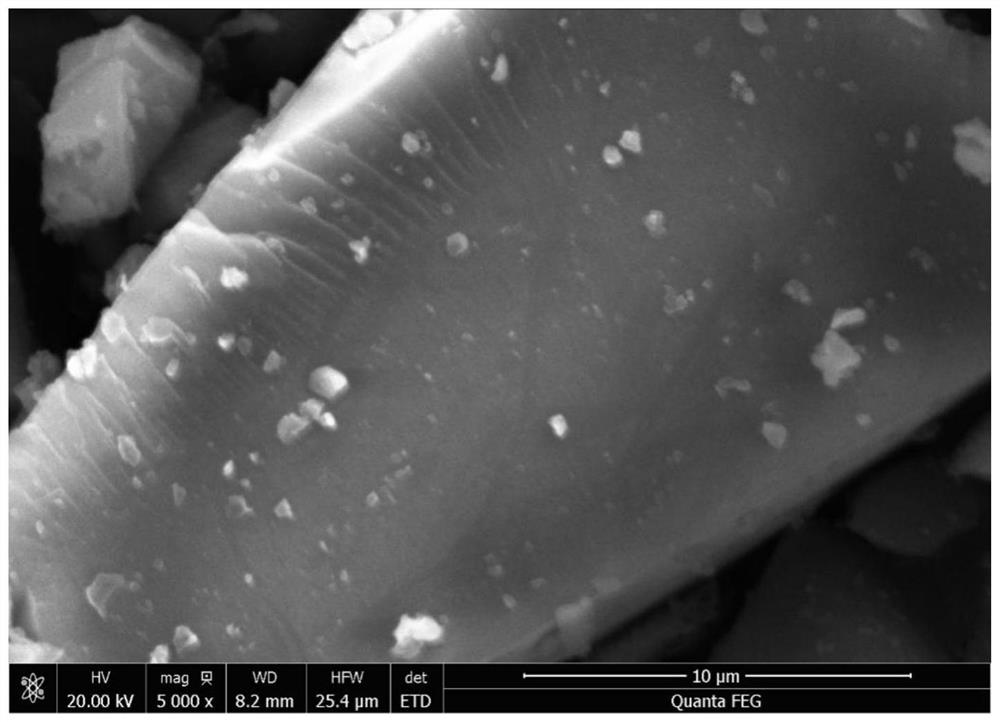

[0030] Weigh 12.4g of sodium silicate and 49.6g of water, add to the reaction kettle to start stirring and heating, set the stirring rate to 300rpm and heat to the reaction temperature of 85°C, after the sodium silicate is completely dissolved, weigh 9.5g of mineral powder and Add it to the reaction kettle, keep the stirring rate and reaction temperature constant, and continue stirring for 5.0 hours to obtain the hot alkali-activated mineral powder crystal nucleus early strength agent.

Embodiment 2

[0032] Weigh 8.6g of sodium silicate and 28.4g of water, add them into the reaction kettle to start stirring and heating, set the stirring rate to 400rpm and heat to the reaction temperature of 70°C. After the sodium silicate is completely dissolved, weigh 8.6g of mineral powder and add it to the reaction kettle, keep the stirring rate and reaction temperature constant, and continue stirring for 6.0 hours to obtain the hot alkali-activated mineral powder crystal nucleus early strength agent.

Embodiment 3

[0034] Weigh 10.0 g of sodium hydroxide and 60.5 g of water, add them into the reaction kettle to start stirring and heating, set the stirring rate to 250 rpm and heat to the reaction temperature of 80°C. After the sodium silicate is completely dissolved, weigh 9.5g of mineral powder and add it to the reaction kettle, keep the stirring rate and reaction temperature constant, and continue stirring for 3.0 hours to obtain the hot alkali-activated mineral powder crystal nucleus early strength agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com