Caprolactam recovered in process of preparing nylon 6 through hydrolysis ring-opening polymerization of caprolactam and application of cyclic oligomer mixture of caprolactam

A technology of cyclic oligomers and caprolactam water, which is applied in the separation/purification of lactam, organic chemistry, chemical instruments and methods, etc., can solve the problems of increased polymerization cost and decreased quality of nylon 6 slices, and achieves powerful functions , Improve application value, good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following examples are intended to further illustrate the practical application effect of caprolactam and its cyclic oligomers provided by the present invention in the field of modification of polyamide engineering plastics, rather than limit the protection scope of the claims of the present invention.

[0033] 1. Example of caprolactam and its cyclic oligomer mixture:

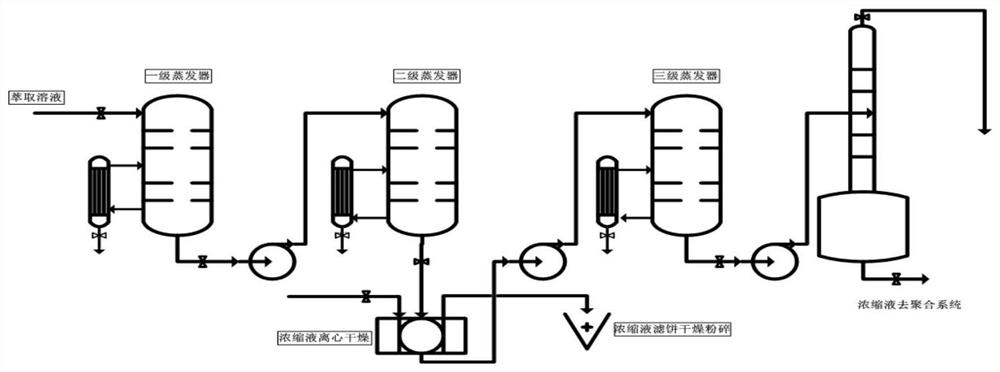

[0034] Continuously transport 1000kg of caprolactam and its oligomer mixture containing 20% to the first stage, the second stage and the third stage of the three-effect evaporator through a metering pump, and evaporate continuously at 120°C and a gauge pressure of -0.08MPa under vacuum and reduced pressure Concentrate and remove water. After the second stage of concentration and evaporation is completed, the concentrated liquid continuously enters the centrifuge to collect the filter cake by centrifugation and washes it once with 50kg of cold water. Most of the caprolactam and cyclic oligomers diss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com