Modified antistatic PC plastic

An anti-static and plastic technology, applied in the field of plastic modification, can solve the problems of slow migration of anti-static agents, difficulty in forming anti-static water film, poor performance of anti-static materials, etc., to reduce static electricity and prevent damage to electronic components Or aging problems, the effect of compatibility improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

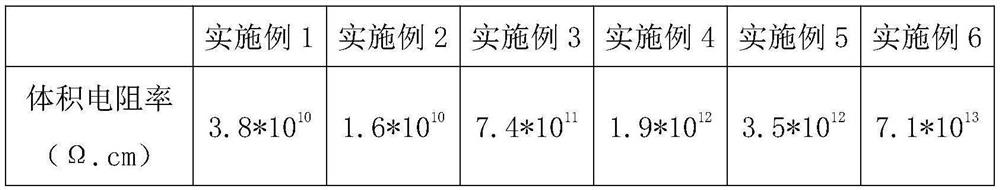

Embodiment 1

[0023] Preparation of anti-static particles: Mix 3kg of maleic anhydride, 10kg of PC material, and 11kg of ABS material evenly, then heat to 220-260°C, then add 6kg of methacryloyloxyethyltrimethylammonium chloride polymer, and blow in nitrogen , carry out antistatic graft modification of PC and ABS materials at 320-360°C, add 16kg of polyether ester amide at 190-240°C after 20-50 minutes for compatibility modification, and then mix the modified The material is put into a granulator to granulate to obtain the antistatic particles of Example 1.

[0024] The preparation of modified antistatic PC plastics comprises the following steps: step a, preparing antistatic particles; step b, adding 5 parts by weight of antistatic particles and 100 parts by weight of PC material into a twin-screw extruder to melt, extrude and granulate , the extrusion temperature is 180° C. to 210° C. to obtain the modified PC plastic of Example 1.

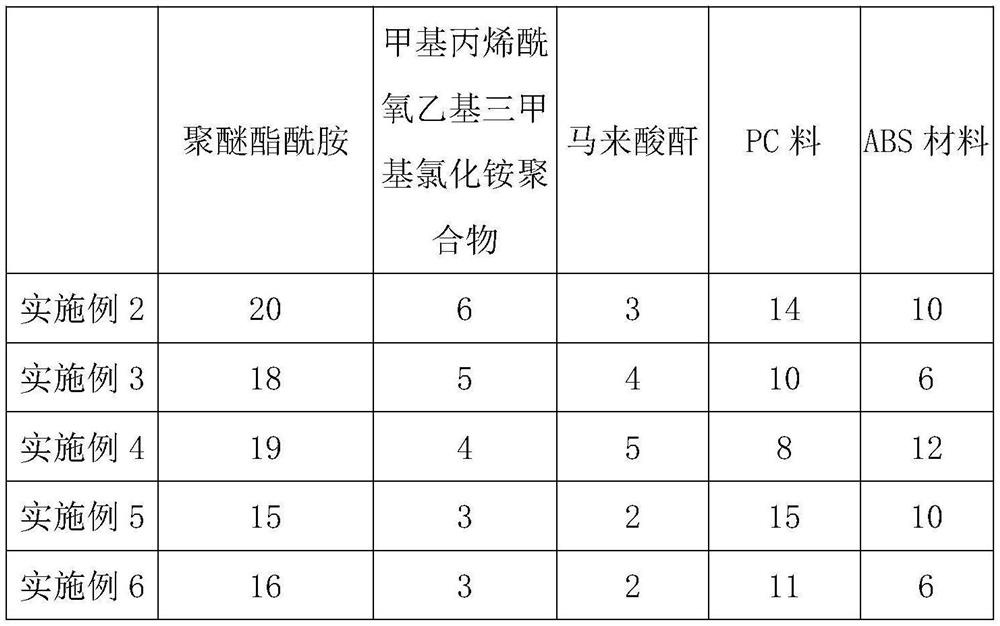

[0025] The preparation method and formula of embodiment...

Embodiment 7

[0033] Preparation of antistatic particles: Mix 3kg of maleic anhydride, 10kg of PC material, 11kg of ABS material, 6kg of methacryloyloxyethyltrimethylammonium chloride polymer and 16kg of polyether ester amide, and heat to 220-260°C. Antistatic grafting modification of PC and ABS materials was carried out at a temperature of 320-360° C., and then the modified mixture was put into a granulator for granulation to obtain the antistatic particles of Example 7.

[0034] The preparation of modified antistatic PC plastics comprises the following steps: step a, preparing antistatic particles; step b, adding 5 parts by weight of antistatic particles and 100 parts by weight of PC material into a twin-screw extruder to melt, extrude and granulate , the extrusion temperature is 180° C. to 210° C., and the modified PC plastic of Example 7 is obtained.

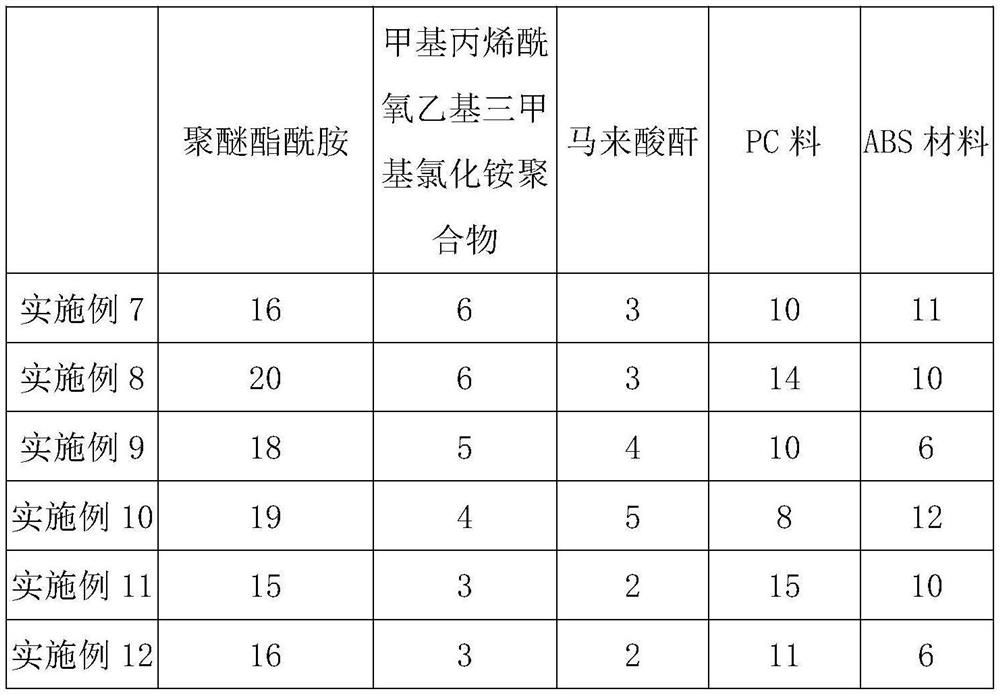

[0035] The preparation method and formula of embodiment 8-12 refer to Example 7, the preparation method of antistatic particles refers t...

Embodiment 13

[0041] Embodiment 13: The formulation and preparation method of modified PC plastics and antistatic particles are as follows:

[0042] Preparation of anti-static particles: Mix 3kg of maleic anhydride, 10kg of PC material, and 11kg of ABS materials evenly, then heat to 220-260°C, then add 6kg of methacryloyloxyethyltrimethylammonium chloride, and blow in nitrogen, Carry out anti-static graft modification of PC and ABS materials at 320-360°C, add 16kg of polyether ester amide at 190-240°C after 20-50 minutes for compatibility modification, and then put the modified mixture Enter granulator granulation, obtain the antistatic particle of embodiment 1.

[0043] The preparation of modified antistatic PC plastics comprises the following steps: step a, preparing antistatic particles; step b, adding 5 parts by weight of antistatic particles and 100 parts by weight of PC material into a twin-screw extruder to melt, extrude and granulate , the extrusion temperature is 180° C. to 210° C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com