Flushing device for safety protection textile materials for spinning

A textile material and washing device technology, which is applied in the processing of textile material equipment configuration, textile material processing, textile material cutting, etc., can solve the problems of reducing production efficiency, wasting manpower, and affecting processing, so as to improve production efficiency and improve The effect of improving efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

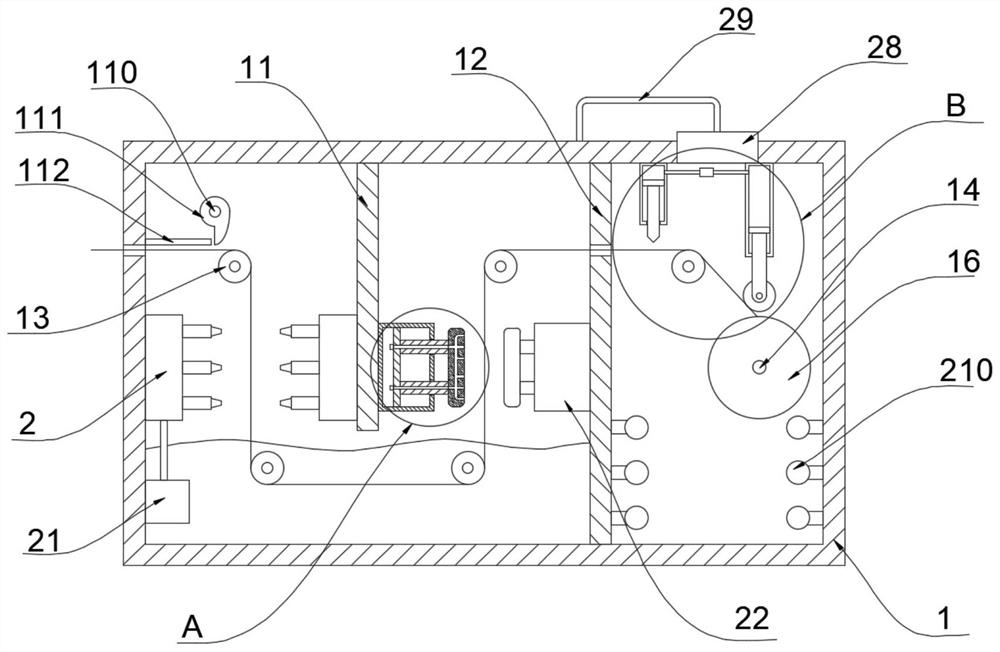

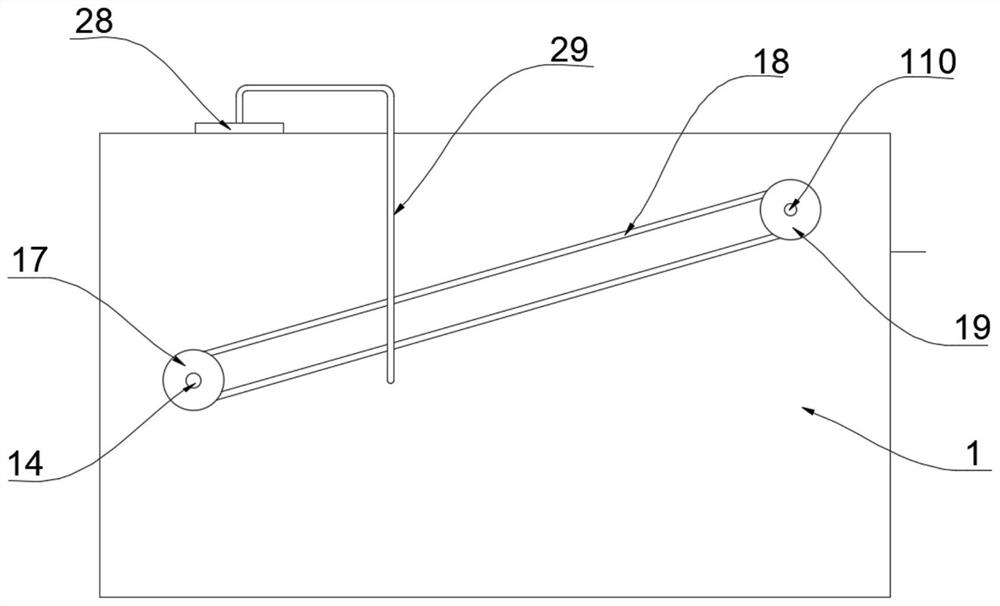

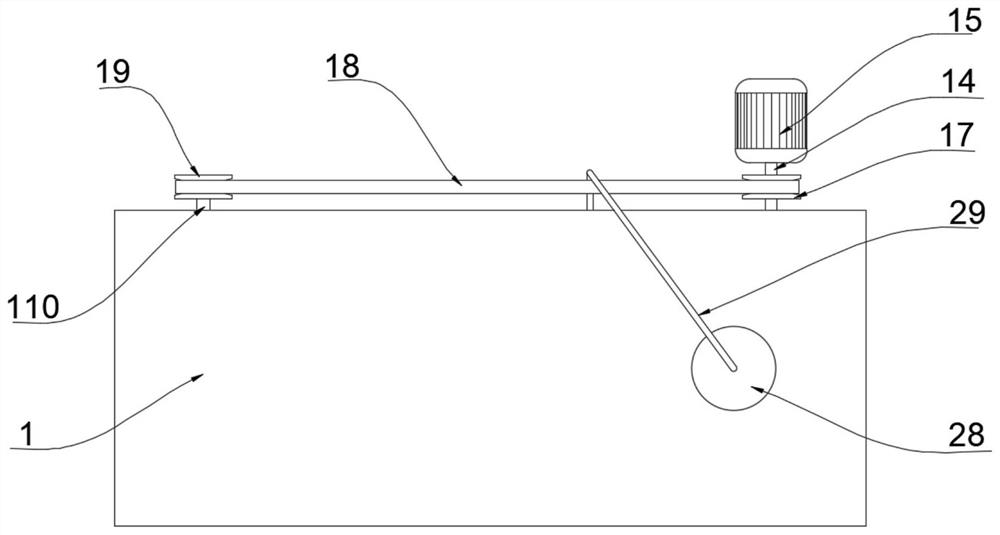

[0022] refer to Figure 1-5 , a textile safety protection textile material washing device, including a box 1, a winding mechanism, which is used for winding the cloth, a flushing ironing mechanism, which is used for cleaning, ironing and drying the cloth, and a cutting mechanism , which is used to cut the fabric, the winding mechanism includes a first partition 11 fixedly connected to the inside of the box 1, a second partition 12 is fixedly connected to the inside of the box 1, and a number of limiters are connected to the inside of the box 1 for rotation. The roller 13 and the second partition 12 divide the inside of the box 1 into a large cavity and a small cavity. The small cavity inside the box 1 is rotatably connected with a first shaft 14, and the outer wall of the box 1 is fixedly connected with a servo motor 15. The output end of the servo moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com