Equipment and method for detecting performance of automotive electronic thermal insulation material

A technology for thermal insulation materials and automotive electronics, which is used in analytical materials, suspension and porous material analysis, measurement devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

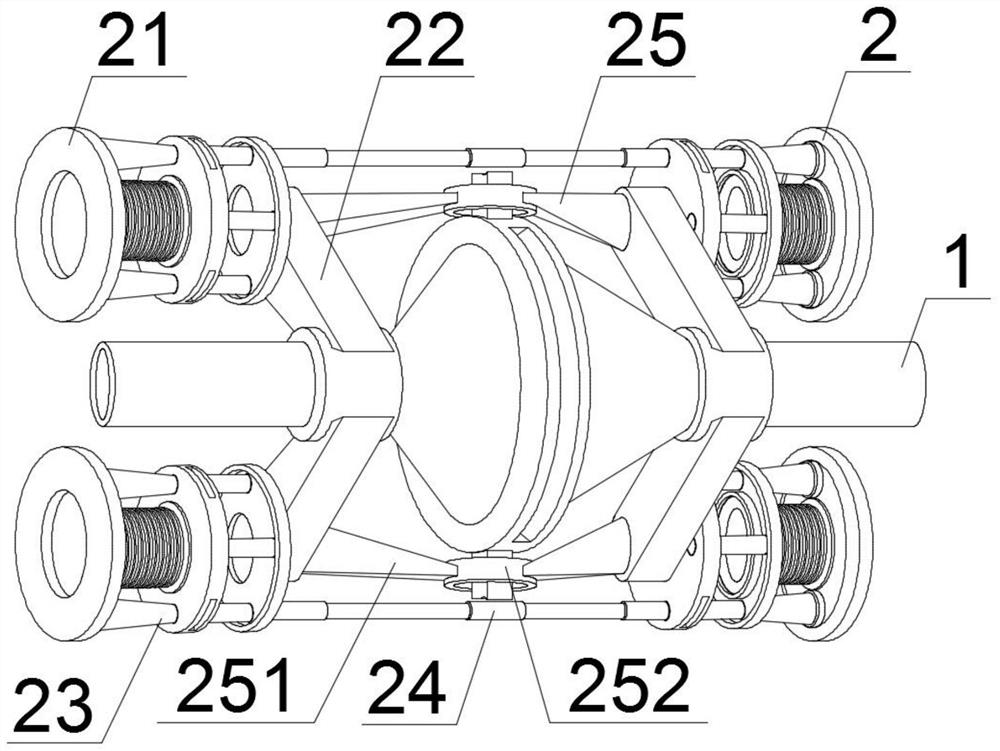

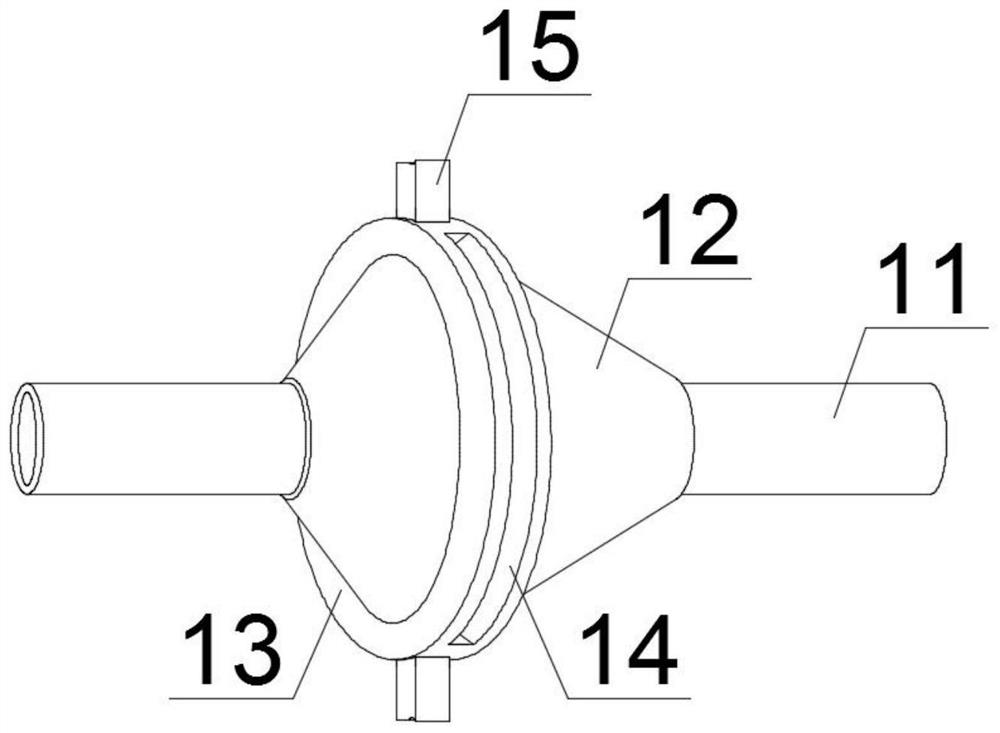

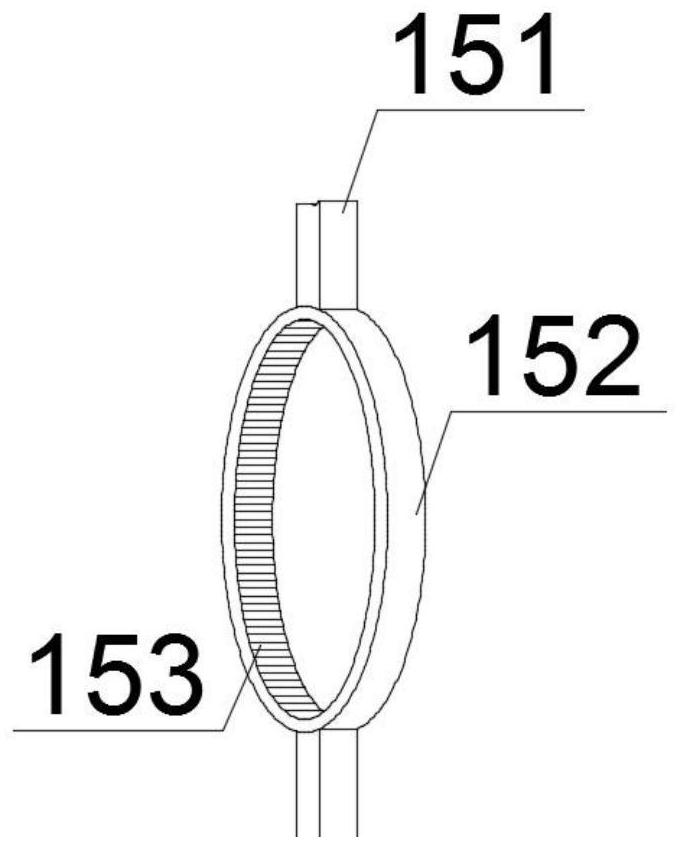

[0035] like Figure 1-4As shown, the performance testing equipment for automotive electronic thermal insulation materials includes an adjustment mechanism 1 and a detection mechanism 2. The inner cavity of the detection mechanism 2 is equipped with an adjustment mechanism 1. The adjustment mechanism 1 includes an inner rotation rod 11, a series connection shell 12, an assembly ring 13, The side slot 14 and the ventilation mechanism 15 are installed between the inner rotation rods 11. The series connection shell 12 is installed. The outer ring of the series connection shell 12 is equipped with an assembly ring 13. The two ends of the assembly ring 13 are provided with side slots 14. The assembly ring The inner cavity of 13 is provided with a ventilation mechanism 15, and the ventilation mechanism 15 includes a ventilation outer cylinder 151, an inner ring 152 and an inner groove 153, and an inner ring 152 is installed between the ventilation outer cylinder 151, and the inner cav...

Embodiment 2

[0037] like Image 6 As shown in the performance testing equipment for automotive electronic thermal insulation materials, the first adjustment mechanism 21 includes a mounting plate 211, a central connecting horizontal cylinder 212, an edge column 213, an assembly plate 214, an inner connecting plate 215, an assembling column 216 and an inner connecting plate 217, and the mounting plate 211 The side end of the middle connecting horizontal cylinder 212 is installed, the two ends of the connecting horizontal cylinder 212 are installed with the edge column 213, the other end of the connecting horizontal cylinder 212 and the edge column 213 is installed with the assembly plate 214, and the side end of the assembly plate 214 is installed There is an inner disc 215, the outer ring of the inner disc 215 is equipped with an assembly column 216, and the other end of the assembly column 216 is equipped with an inner disc 217, and the inner disc 217 includes a disc body 2171, a through h...

Embodiment 3

[0039] like Figure 5 As shown in the performance testing equipment for automotive electronic thermal insulation materials, the telescopic mechanism 24 includes an installation shell 241, an inner elastic shaft 242, a middle connecting shell 243 and an adjustment bar 244, and an inner elastic shaft 242 is installed between the installation shells 241, and the inner elastic shaft 242 The middle joint shell 243 is installed in the middle of the outer ring, and the bottom end of the middle joint shell 243 is equipped with an adjustment bar 244. The heat insulation material to be tested is placed into the inner cavity of the assembly ring 13 through the side slot 14, and the installation shell is adjusted by an external motor. 241 rotates, adjusts its rotation angle through the rotation of the installation shell 241, and can push the inner elastic shaft 242 to expand and contract, thereby adjusting the distance of the whole device. The serial connection mechanism 25 includes a conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com