Bio-based all-fiber self-powered multifunctional electronic skin and preparation method thereof

An electronic skin, self-powered technology, applied in the direction of fiber chemical characteristics, conductive/antistatic filament manufacturing, conjugated synthetic polymer artificial filament, etc., can solve the problem of incomplete use of multifunctional electronic skin, complicated production process, expensive Manufacturing and other issues, to achieve the effect of humidity and temperature sensitivity and good detection range, high air permeability, excellent pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

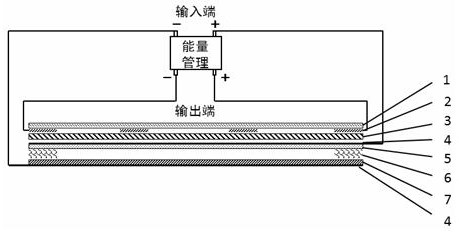

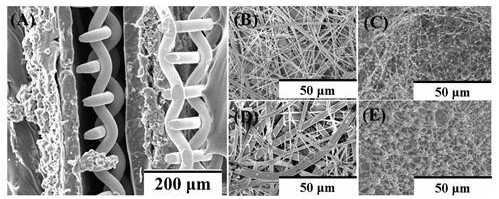

[0066] (1) Preparation of polyvinyl alcohol / polyvinylidene fluoride negative friction layer: Dissolve polyvinyl alcohol in deionized water at 80°C, stir for 3 h, and the concentration is 18 wt%. Add 1 wt% polyvinylidene fluoride powder and stir for 10 h to obtain a uniform dispersion with a concentration of 19 wt% polyvinyl alcohol / polyvinylidene fluoride. Fix the copper mesh on the collector at a distance of 10 cm from the needle, uniformly covered by polyvinyl alcohol / polyvinylidene fluoride nanofibers. The electrospinning machine was kept under certain spinning conditions during the working process, and the feed rate was 1 mL∙h –1 . Finally, the samples were dried in an oven at 30 °C for 6 h to remove residual solvents.

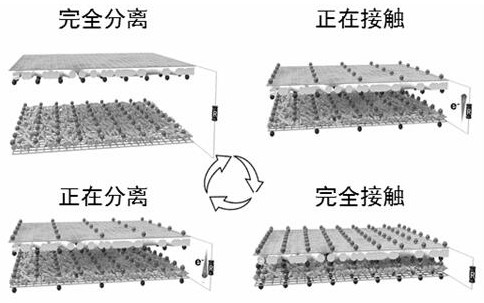

[0067] (2) Preparation of the positive friction layer of collagen aggregates and assembly of the self-generating pressure-sensitive layer: 5 wt% collagen aggregates were dissolved in hexafluoroisopropanol and stirred at 30°C for 40 min. Electrospinning ...

Embodiment 2

[0072] (1) Preparation of polyvinyl alcohol / polyvinylidene fluoride negative friction layer: Dissolve polyvinyl alcohol in deionized water at 90 °C, stir for 5 h, and the concentration is 9 wt%. Add 9 wt% polyvinylidene fluoride and stir for 20 h to obtain a uniform dispersion of 18 wt% polyvinyl alcohol / polyvinylidene fluoride. Fix the copper mesh on the collector at a distance of 15 cm from the needle, uniformly covered by polyvinyl alcohol / polyvinylidene fluoride nanofibers. The electrospinning machine was kept under certain spinning conditions during the working process, and the feed rate was 1.5 mL∙h –1 . Finally, the samples were dried in an oven at 50 °C for 3 h to remove residual solvents.

[0073] (2) Preparation of the positive friction layer of collagen aggregates and assembly of the self-generating pressure-sensitive layer: 10 wt% collagen aggregates were dissolved in hexafluoroisopropanol and stirred at 40°C for 30 min. Electrospinning under certain environment...

Embodiment 3

[0078] (1) Preparation of polyvinyl alcohol / polyvinylidene fluoride negative friction layer: Dissolve polyvinyl alcohol in deionized water at 100 °C, stir for 1 h, and the concentration is 1 wt%. Add 17 wt% polyvinylidene fluoride powder and stir for 10-30 h to obtain a uniform dispersion of 18 wt% polyvinyl alcohol / polyvinylidene fluoride. Fix the copper mesh on the collector at a distance of 20 cm from the needle, uniformly covered by polyvinyl alcohol / polyvinylidene fluoride nanofibers. The electrospinning machine was kept under certain spinning conditions during the working process, and the feed rate was 2 mL∙h –1 . Finally, the samples were dried in an oven at 70 °C for 1 h to remove residual solvents.

[0079] (2) Preparation of the positive friction layer of collagen aggregates and assembly of the self-generating pressure-sensitive layer: 18 wt% collagen aggregates were dissolved in hexafluoroisopropanol and stirred at 50°C for 10 min. Electrospinning under certain e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com