Temperature-sensitive gel material composition as well as preparation method and application thereof

A temperature-sensitive gel and gel technology, applied in the field of regenerative medicine, can solve the problems of increased cost and high requirements of 3D printing technology, and achieve the effect of promoting regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present invention also provides a method for preparing a temperature-sensitive gel material combination, comprising the following steps:

[0043] (1) chitosan is mixed with acetic acid solution to obtain chitosan solution;

[0044] (2) dissolving β-glycerophosphate disodium and hyaluronic acid in water to obtain a hyaluronic acid solution;

[0045] (3) chitosan solution is mixed with hyaluronic acid solution to obtain chitosan hyaluronic acid solution;

[0046] (4) mixing SDF-1 with 40-60% volume chitosan hyaluronic acid solution to obtain a chitosan hyaluronic acid solution loaded with SDF-1;

[0047] (5) Mix 40-60% volume chitosan hyaluronic acid solution with 1-ethyl-(3-dimethylaminopropyl) carbodiimide and N-hydroxysuccinimide, then add Apt19S aptamer, Apt19S-loaded chitosan hyaluronic acid solution was obtained.

[0048] The invention mixes chitosan with acetic acid solution to obtain chitosan solution.

[0049] In the present invention, the concentration of ...

Embodiment 1

[0092] Dissolve 48mg of chitosan (CS) in 1.6mL of 0.1M acetic acid solution, place it on a magnetic stirrer for 2h (1000rpm), and sterilize it by high-pressure steam at 121°C for 10min to form the chitosan solution. 240 mg of β-GP and 4 mg of hyaluronic acid were dissolved in 0.4 mL of deionized water, and sterilized by filtration with a 0.22 μm filter membrane to obtain a hyaluronic acid solution. Put chitosan solution and hyaluronic acid solution in ice bath (0°C) for 15min, then add hyaluronic acid dropwise into chitosan solution and stir with magnetic stirrer for 10min (1000rpm) to obtain chitosan hyaluronic acid solution . The chitosan hyaluronic acid solution was equally divided into two parts, each 1 mL.

[0093] Take 1mL chitosan-hyaluronic acid solution, add 1μl of SDF-1 solution with a concentration of 100μg / mL dissolved in PBS dropwise, and magnetically stir for 10min (1000rpm) to obtain a loaded SDF with a SDF-1 concentration of 200ng / mL. -1 chitosan hyaluronic a...

Embodiment 2

[0098] 100 μL of the third-generation rBMSCs culture solution (containing 1 × 10 3 cells) were inoculated into the upper chamber of the Transwell chamber, and 600 μL of α-MEM medium containing 200 ng / mL SDF-1 and 600 μL of α-MEM medium containing amino-modified Apt19S at a concentration of 2 nmol / mL were added to the lower chamber of the Transwell. at 37°C, CO 2 After culturing in an incubator with a concentration of 5% for 24 hours, wipe off the non-migrated cells in the upper chamber with a cotton swab, and fix the cells that migrated to the lower chamber with 4% formaldehyde for 15 minutes, wash with PBS twice, and dry them in the air, then 0.5% crystal violet for 30 minutes, Rinse with PBS 3 times. Then 5 fields of view were randomly selected in each small chamber under the microscope, and the BMSC cells migrating to the lower chamber were counted. The results showed that the addition of SDF-1 and amino-modified Apt19S aptamers could significantly promote the migration o...

PUM

| Property | Measurement | Unit |

|---|---|---|

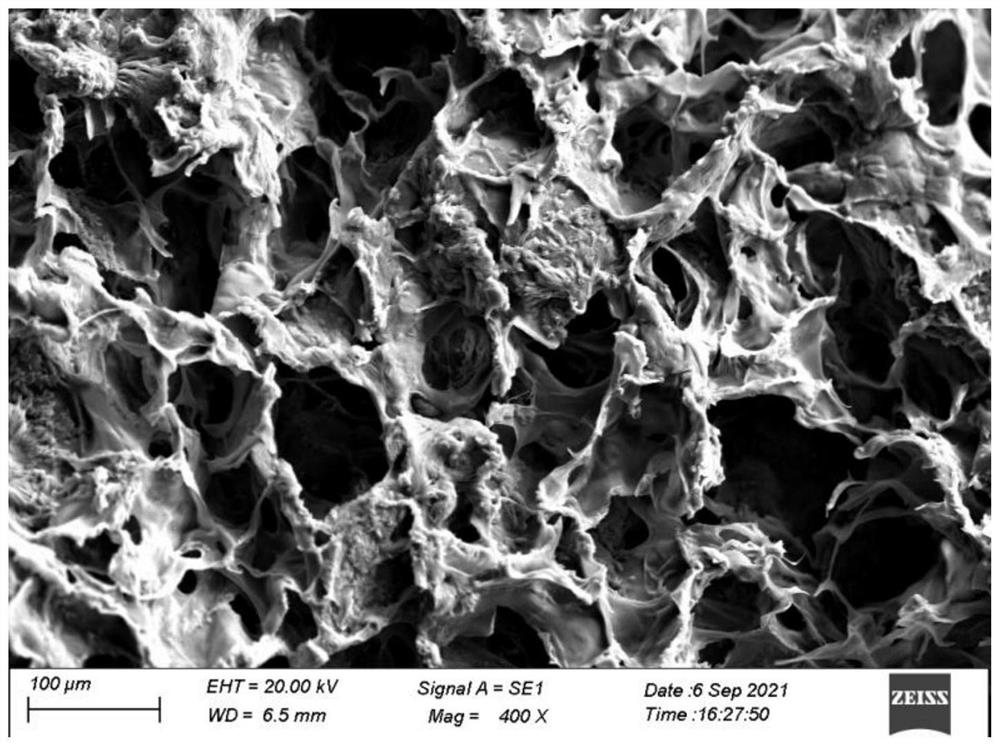

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com