Fully-closed liposuction tank

A fully-sealed, tank-based technology, applied in the direction of suction devices, bone/connective tissue cells, drug devices, etc., can solve the problem of reduced fat volume retention, obstacles to the survival and activity of fat cells, no heating or heat preservation functions, etc. To avoid large temperature fluctuations, ensure activity and survival rate, and reduce injection fat contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

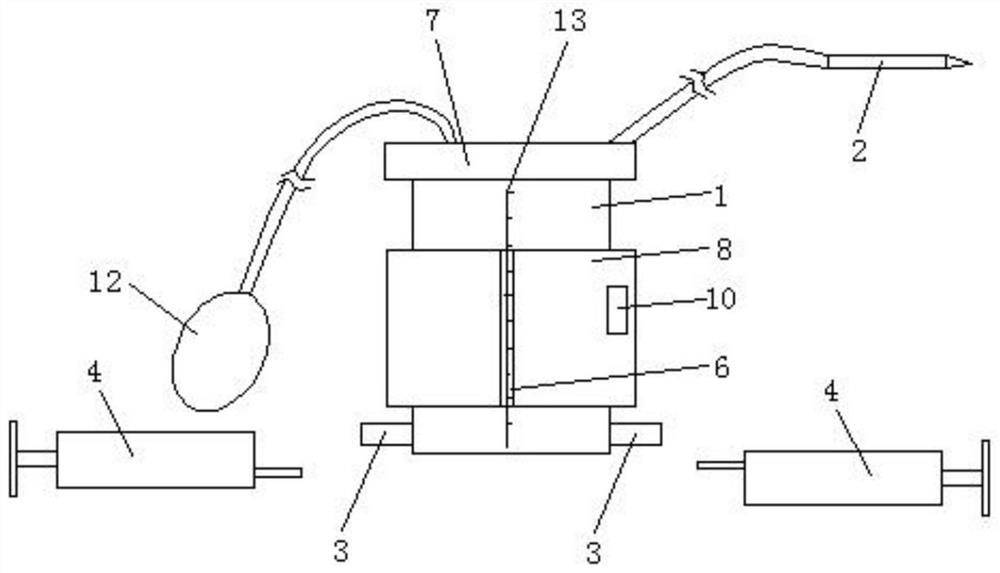

[0037] Such as Figure 1 to Figure 4 As shown, this embodiment provides a fully enclosed liposuction tank, including a tank body 1, a negative pressure member and a liposuction needle 2, the top of the tank body 1 is provided with an inlet, and the bottom is provided with at least one outlet 3, each outlet Valves are fixedly installed at all 3 places, and the tank body 1 is detachably wrapped with a thermal insulation mechanism; the negative pressure part communicates with the top of the tank body 1 through the negative pressure tube, and the liposuction needle 2 communicates with the inlet through the liposuction tube.

[0038] During liposuction, firstly, the needle of the liposuction needle 2 is inserted into the position of the patient to be liposuctioned; then, a negative pressure is generated in the tank body 1 through the negative pressure member, so as to suck the fat in the patient's body into the tank body 1, and Finally, after standing for a period of time (15-30 mi...

Embodiment 2

[0045] On the basis of Embodiment 1, this embodiment further includes a plurality of syringes 4, which are respectively used to extract swelling fluid or adipose tissue from the outlet 3. After the liposuction is completed, the swelling liquid in the tank 1 can be sucked sequentially through the syringe 4 to realize a fully enclosed operation, avoiding the contact of the fat tissue with air, and ensuring that the fat tissue is not polluted.

[0046] Preferably, in this embodiment, the number of syringes 4 is preferably two, and corresponds to the two outlets 3 one-to-one. After the fat in the tank 1 is statically divided, the medical staff draws it out from one of the outlets 3 through one of the syringes 4 Swelling fluid, after the swelling fluid is exhausted, close the valve; then draw the adipose tissue in the tank body 1 from another outlet 3 through another syringe 4, and inject the adipose tissue into the corresponding part of the patient through the syringe 4.

[0047] ...

Embodiment 3

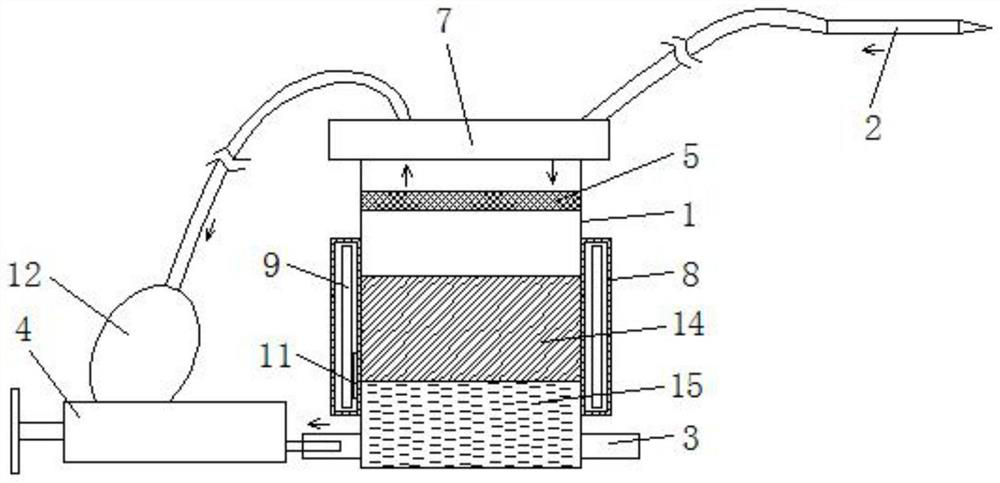

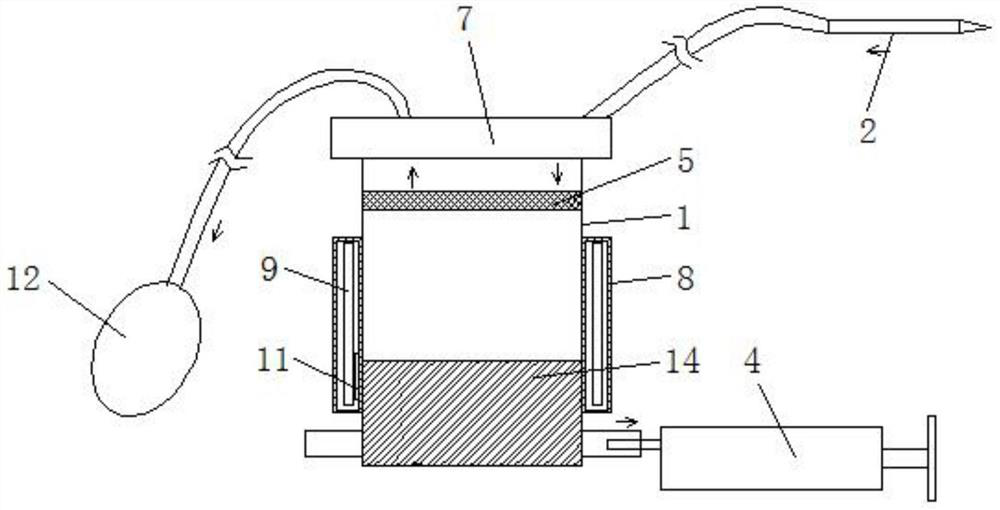

[0050] On the basis of any one of Embodiment 1 to Embodiment 2, in this embodiment, a filter element 5 is fixedly installed in the tank body 1 , and the filter element 5 is located above the outlet 3 . During liposuction, fibrous cords and broken tissues in the fat are filtered and removed by the filter member 5, so that the upper layer is the adipose tissue layer 14 and the lower layer is the obvious layering phenomenon of the swelling fluid after standing, so as to realize the separation of the fat tissue and the swelling fluid. Effective separation to purify adipose tissue.

[0051] Preferably, in this embodiment, the filter element 5 preferably adopts a filter plate, which is horizontally and fixedly installed on the upper part of the tank body 1, and can effectively remove fiber strands and broken tissues in the fat, so that the upper layer is fat after standing. The tissue layer 14 and the lower layer are obviously stratified by the swelling fluid, so as to realize the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com