Mud-sand separation and oil sludge dehydration drying treatment equipment and treatment process

A technology of treatment equipment and treatment process, which is applied in the directions of dehydration/drying/concentrated sludge treatment, water/sludge/sewage treatment, sludge treatment, etc. High cost and other issues, achieve the effect of realizing resource reuse, improving processing efficiency and improving economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

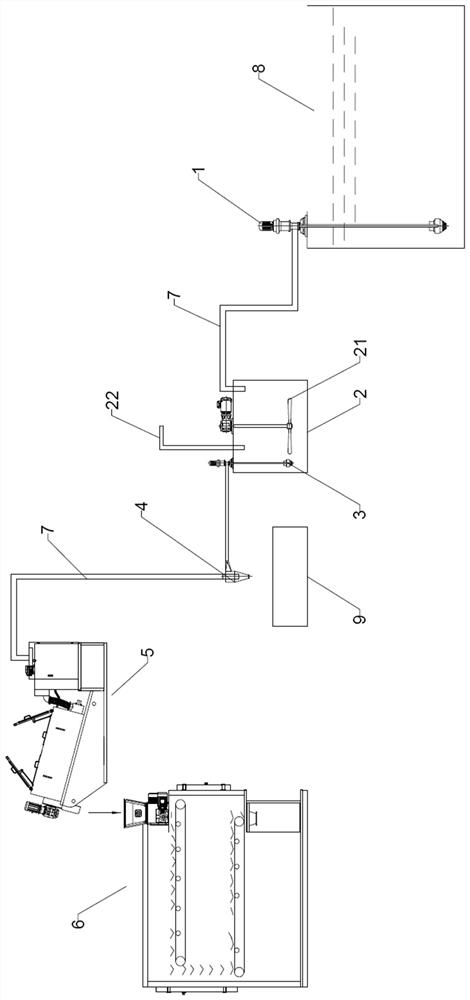

[0031] Such as figure 1 The mud-sand separation and sludge dehydration and drying treatment equipment shown includes a submersible sand mining pump 1, a sand washing tank 2, a submersible pump 3, a cyclone 4, a dehydrator 5, and a drying machine 6. The submersible sand mining pump 1 The output end of the submersible pump 3 is connected to the sand washing tank 2 through the delivery pipeline 7, the input end of the submersible pump 3 is arranged in the sand washing tank 2, and the output end of the submersible pump 3 is connected to the feed port of the cyclone 4 through the delivery pipeline 7 The overflow port of the cyclone 4 is connected to the feed port of the dehydrator 5 through the delivery pipe 7, and the discharge port of the dehydrator 5 is connected to the feed port of the drying machine 6.

[0032] Wherein, the input end of the submersible sand mining pump 1 is set in the oil sludge tank 8 .

[0033] Moreover, the sand washing tank 2 is provided with a stirring p...

Embodiment 2

[0037] The treatment process of the mud-sand separation and oil sludge dehydration and drying treatment equipment described in embodiment 1 comprises the following steps:

[0038] ① Use the submersible sand mining pump 1 to pump the sludge from the sludge tank 8 to the sand washing tank 2;

[0039] ②Start the stirring paddle 21, and at the same time inject hot water with a water temperature of 40-50°C into the sand washing tank 2 through the hot water injection pipe 22. The stirring paddle 21 rotates at a speed of 200 rpm. mix;

[0040] ③The sludge water mixed in step ② is pumped into the cyclone 4 through the submersible pump 3, and the sludge water is driven to rotate by the guide vanes in the cyclone 4. The bottom of the cyclone 4 is discharged into the sand storage tank 9; the sludge water without sand shrinks in the cyclone 4 and flows to the center, and is discharged upward from the overflow port into the dehydrator 5;

[0041] ④The oil sludge water without sand and gr...

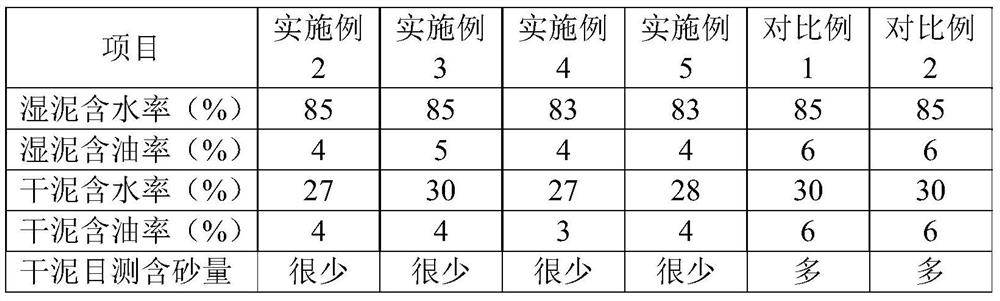

Embodiment 3

[0046] The treatment process of the mud-sand separation and oil sludge dehydration and drying treatment equipment described in embodiment 1 comprises the following steps:

[0047] ① Use the submersible sand mining pump 1 to pump the sludge from the sludge tank 8 to the sand washing tank 2;

[0048] ②Start the stirring paddle 21, and at the same time inject hot water with a water temperature of 40-50°C into the sand washing tank 2 through the hot water injection pipe 22. mix;

[0049] ③The sludge water mixed in step ② is pumped into the cyclone 4 through the submersible pump 3, and the sludge water is driven to rotate by the guide vanes in the cyclone 4. The bottom of the cyclone 4 is discharged into the sand storage tank 9; the sludge water without sand shrinks in the cyclone 4 and flows to the center, and is discharged upward from the overflow port into the dehydrator 5;

[0050] ④The oil sludge water without sand and gravel is firstly concentrated by gravity at the front e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com