Method for preparing antifogging transparent coating from modified silane coupling agent and hydrophilic copolymer

A hydrophilic copolymer, silane coupling agent technology, applied in coatings, polyether coatings, etc., can solve problems affecting the normal use of optical equipment, inconvenience, turbidity, etc., achieve high transparency and mechanical properties, improve resistance Abrasion and adhesion, good anti-fog effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

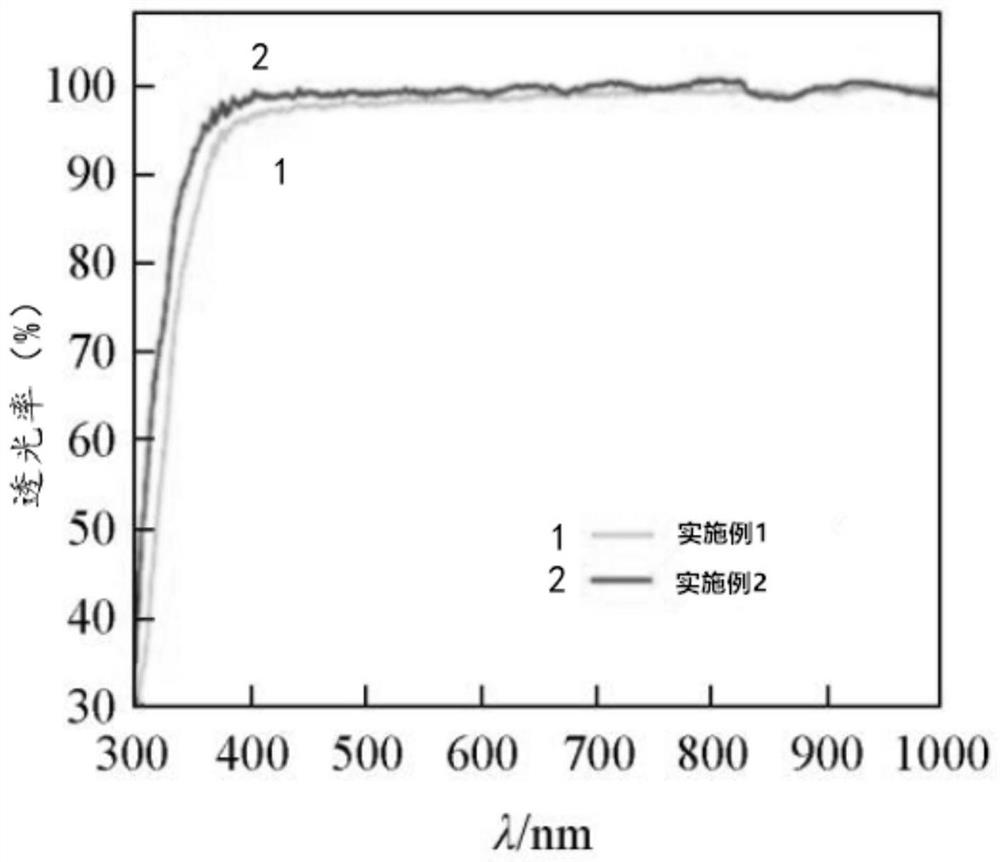

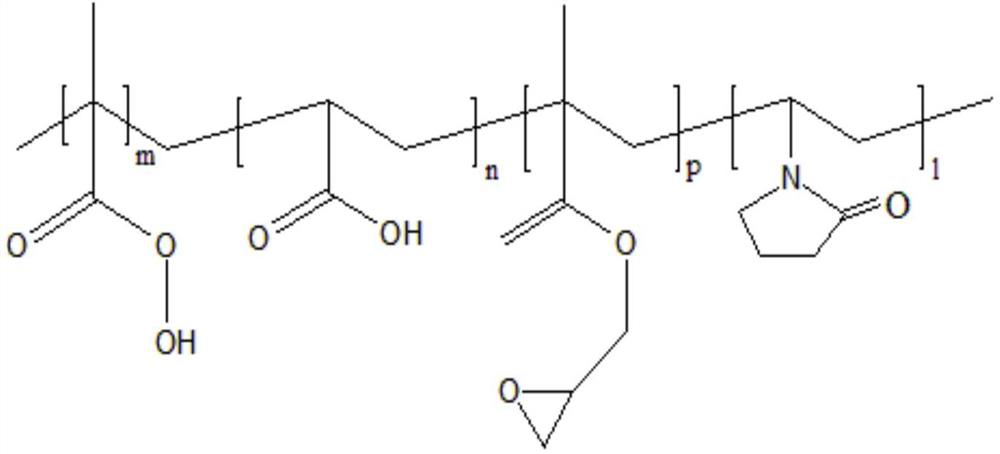

[0028] (1) Synthesis of hydrophilic polymer: 9.10g (0.07mol) hydroxyethyl methacrylate, 0.72g (0.01mol) acrylic acid, 1.11g (0.01mol) N-vinylpyrrolidone and 1.42g (0.01mol) ) Glycidyl methacrylate (GMA) was mixed evenly, and 9.00 g (0.1 mol) of 2-ethoxyethanol solution was added, and stirred evenly. About 15 minutes after nitrogen gas was introduced, 0.06 g (0.000365 mol) of azobisisobutyronitrile was added, the temperature was kept at 80° C., and the reaction was carried out for about 4 hours.

[0029] (2) Synthesis of polyethylene glycol modified silane coupling agent: mix 11.61g (0.058mol) polyethylene glycol 200 and 0.08g (0.000127mol) dibutyltin dilaurate, dissolve in 8g (0.11mol) tetrahydrofuran , dispersed evenly, slowly added 14.36g (0.058mol) isocyanate propyltriethoxysilane dropwise, stirred at 25°C for 24h, and removed the solvent with a rotary evaporator at 40°C, then added dropwise 4.03g (0.019mol) ) TEOS and 0.02g (0.00022mol) 1-methoxy-2-propanol, add 0.5mL ace...

Embodiment 2

[0034] (1) Synthesis of hydrophilic polymer: 13.66g (0.105mol) hydroxyethyl methacrylate, 1.08g (0.015mol) acrylic acid, 1.66g (0.015mol) N-vinylpyrrolidone and 2.13g (0.015mol) ) Glycidyl methacrylate (GMA) was mixed evenly, and 10.00 g (0.11 mol) of 2-ethoxyethanol solution was added, and stirred evenly. About 15 minutes after nitrogen gas was introduced, 0.093 g (0.000564 mol) of azobisisobutyronitrile was added, the temperature was kept at 80° C., and the reaction was carried out for about 4 hours.

[0035] (2) Synthesis of polyethylene glycol modified silane coupling agent: mix 21.48g (0.027mol) polyethylene glycol 800 and 0.08g (0.000127mol) dibutyltin dilaurate, dissolve in 9g (0.125mol) tetrahydrofuran , dispersed evenly, slowly added 6.64g (0.027mol) isocyanate propyltriethoxysilane dropwise, stirred at 25°C for 24h, and removed the solvent with a rotary evaporator at 50°C, then added dropwise 1.87g (0.0089mol) ) TEOS and 0.03g (0.00033mol) 1-methoxy-2-propanol, add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| transparency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com