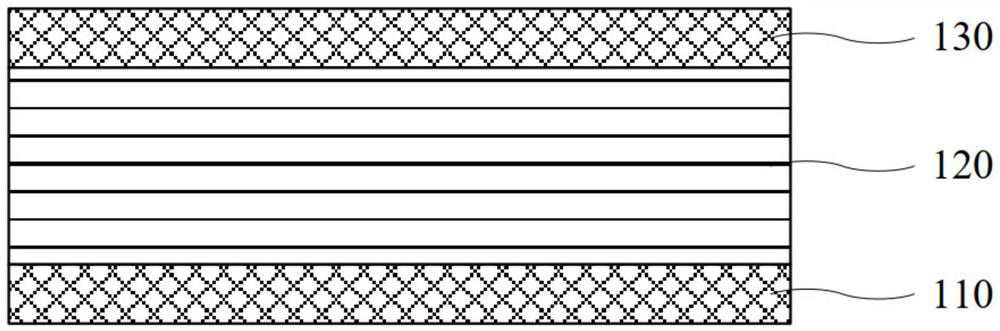

Composite carbon nanotube film, preparation method thereof and layered heating device

A carbon nanotube film and technology of carbon nanotubes, applied in the direction of chemical instruments and methods, coatings, carbon compounds, etc., can solve the problems of limited heat, low conductivity, and difficulty in meeting actual needs of carbon nanotube films, and achieve The effect of heat generation performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038]According to an embodiment of the present invention, a method for preparing a composite carbon nanotube film includes the following steps.

[0039] In step S1, a carbon nanotube base film is obtained, and the carbon nanotube base film includes a layer of carbon nanotube film or a multi-layered carbon nanotube film. Wherein, the carbon nanotube film has first carbon nanotubes arranged in alignment.

[0040] In one specific example, the carbon nanotube base film includes multilayer carbon nanotube films, and the multilayer carbon nanotube films are stacked. Usually, the thickness of a layer of oriented carbon nanotube base film is relatively limited, resulting in relatively large volume resistance and low overall strength, which is not suitable for some application scenarios. Therefore, it is possible to form an overall thicker film by stacking multiple layers of carbon nanotube films. carbon nanotube-based film. Optionally, the number of layers of the aligned carbon nan...

Embodiment 1

[0071] Pull out a carbon nanotube film with a width of about 10 cm from the carbon nanotube array, repeat this step and overlap 50 layers of carbon nanotube films, and at the same time take the method of adding ethanol for infiltration and rolling to make the laminated carbon nanotube film more compact. Densification, followed by drying treatment, to prepare carbon nanotube base film; wherein, the pressure of the pressing roller is 0.4MPa, the moving speed of the pressing roller is 2m / min; the drying temperature is 150°C.

[0072] The obtained carbon nanotube base film is double-sidedly coated with carbon nanotube slurry through a small roll-to-roll doctor blade casting coating roll system; wherein, according to the mass ratio, the carbon nanotube slurry ratio is: 5 % of carbon nanotubes, 1% of PVP; 2.2% of PVDF and the remainder of NMP; the viscosity of the carbon nanotube slurry is 4520cp; the thickness of the blade coating is 200 μm; the blade coating speed is 0.2m / min , th...

Embodiment 2

[0074] Pull out a carbon nanotube film with a width of about 10 cm from the carbon nanotube array, repeat this step and overlap 50 layers of carbon nanotube films, and at the same time take the method of adding ethanol for infiltration and rolling to make the laminated carbon nanotube film more compact. Densification, followed by drying treatment, to prepare carbon nanotube base film; wherein, the pressure of the pressing roller is 0.4MPa, the moving speed of the pressing roller is 2m / min; the drying temperature is 150°C.

[0075] The obtained carbon nanotube base film is double-sided coated with carbon nanotube slurry through a small roll-to-roll doctor blade casting coating roll system; wherein, according to the mass ratio, the carbon nanotube slurry ratio is: 10 % of carbon nanotubes, 3.2% of PVP; 2.5% of PVDF and the remainder of NMP; the viscosity of the carbon nanotube slurry is 7558cp; the blade coating thickness is 200 μm; the blade coating speed is 0.2m / min , the dryi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com