Method for uncoupling yield and productivity of non-catabolic compounds produced by host cells

A catabolism, host cell technology, applied in the field of decoupling between yield and productivity, and can solve problems such as yield reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

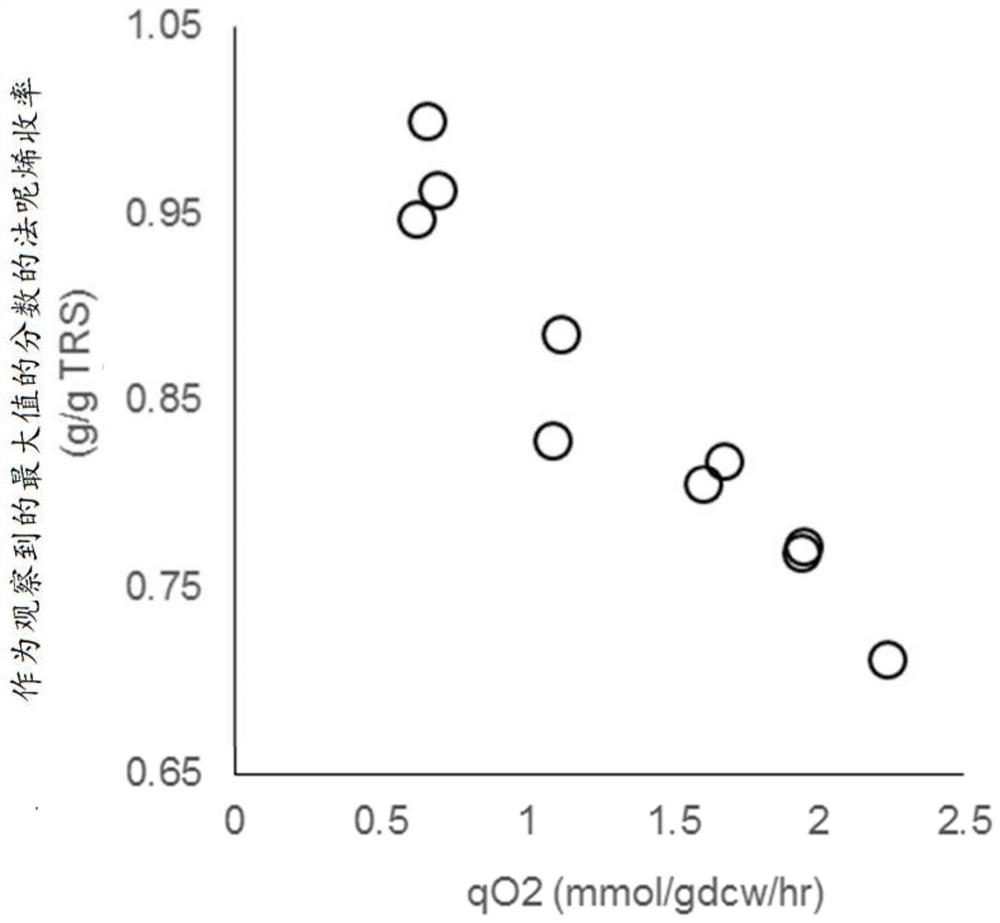

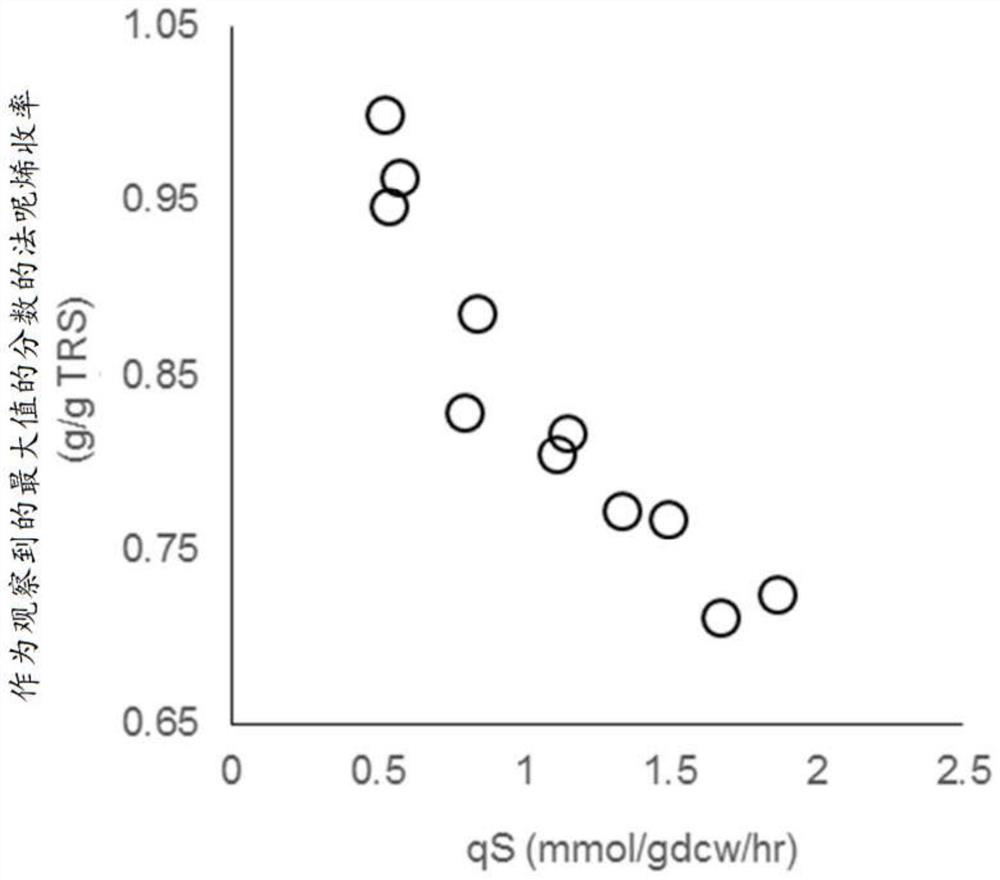

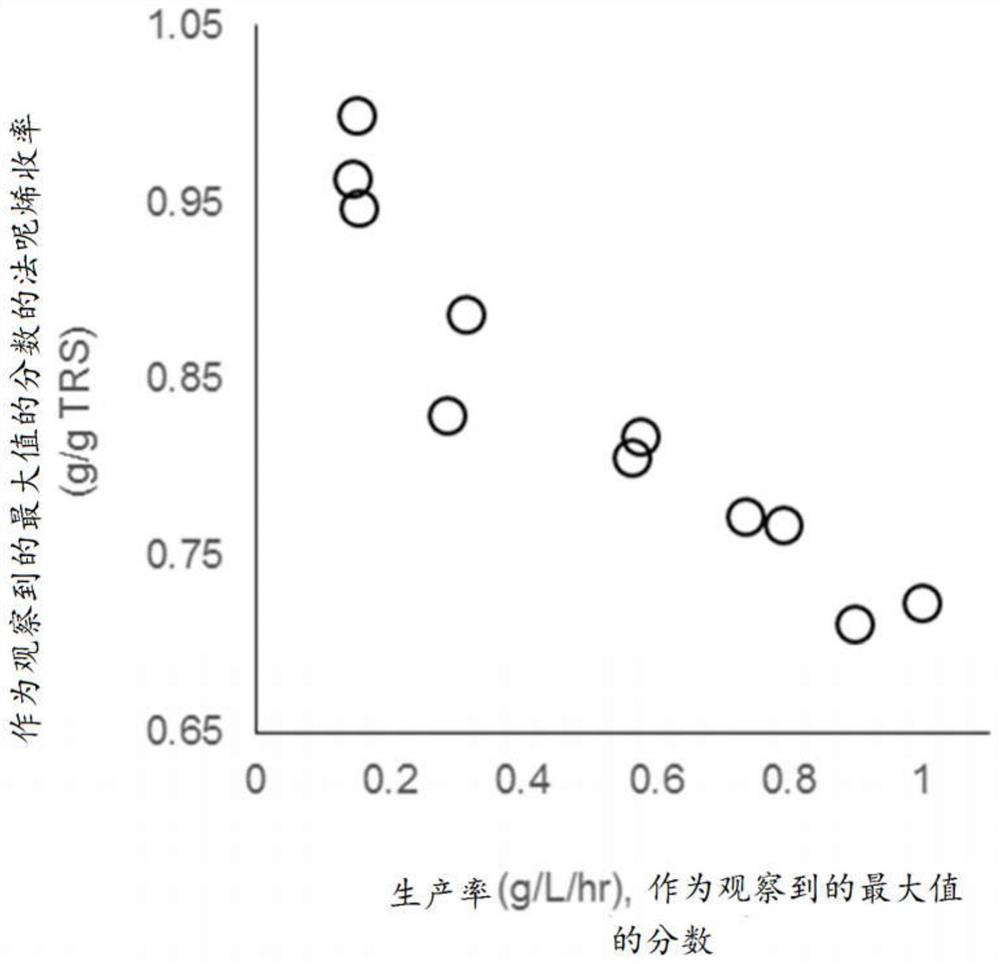

[0129] Example 1: Yield as a function of cell-specific rate

[0130] Inoculate a single colony in 15ml of 2% sucrose, 1% maltose, 2g / L lysine LGM and 50mM succinate pH 5.0 in a 125ml flask, then grow at 28°C and shake at 200r.p.m. to OD600 at 4 Between 9 and 9, with residual glucose between 3 and 6 g, 1-1.50% glycerol was added to the culture to a concentration of 20%, and then the cell suspension was stored in a 1 ml vial at -80°C. Thaw 1-2 flasks of cells in a solution containing 3gl-1 yeast extract, 7gl-1NH4H2PO4, 1gl-1KH2PO4, 0.5gl-1MgSO4·7H2O, 50mM succinate pH 5.0, 4% sucrose, 2% maltose, 2g / L Lysine and trace metal and vitamin solutions were grown for 24 h, and then subcultured in the same medium for 24 h to an OD600 reading of 0.1. 25 ml of culture was used to inoculate a 0.5 liter fermenter (Sartorius, Germany) containing 225ml fermentation medium containing 15g1-1 NH4H2PO4, 20g1-1 total reducing sugars (TRS) from sucrose syrup (Florida Crystals, West Palm Beach), an...

example 2

[0139] Example 2: Computational Modeling and Metabolomics Assays Demonstrate ATP-Driven Coupling Between Rate and Yield

[0140] To assess possible mechanistic reasons for the rate-yield coupling, we analyzed 2 / L / h) or high OTR (180mmol O 2 / L / hr) Absolute concentrations of central metabolites from glycolysis, TCA cycle, pentose phosphate pathway and isoprenoid pathway in fermentation samples of a single strain run. Sampling from the bioreactor was performed using a rapid sampling protocol, in which the sample was quenched immediately after removal from the tank to capture the metabolic state. While most central metabolites were determined at similar absolute concentrations under low and high OTR conditions, two metabolites (isocitrate and α-ketoglutarate) stood out as having very different concentrations (see Figure 5 ). Interestingly, these two metabolites represent successive steps in the TCA cycle: isocitrate can be converted to α-ketoglutarate by the action of isocit...

example 3

[0197] Example 3 - Waste ATP Combustion Increases Product Yield Relative to Biomass

[0198] We hypothesized that excess ATP might affect the rate-yield coupling if biomass is the preferred sink for excess ATP. ATP expenditure for cellular maintenance is constant regardless of the specific ATP generation rate. Thus, at low cell-specific rates, the ATP available for the production of biomass or non-catabolic compounds decreases proportionally, while at high cell-specific rates, the ATP available for the production of biomass or non-catabolic compounds increases proportionally . If the most efficient way to consume excess ATP is for cells to take it up into biomass, then less carbon is available for the production of non-catabolic compounds, and yields at high cell-specific rates decrease. Conversely, at low cell-specific rates, less excess ATP is used to force biomass formation and proportionally more carbon can be shunted to the production of non-catabolic compounds. The hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com