Passivation process of ultrathin double-sided light lithium battery copper foil

A double-sided, copper foil technology, applied in the direction of phosphating, chromate treatment, etc., can solve the problems of chromic anhydride waste, increased chromium content in copper foil, and increased cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

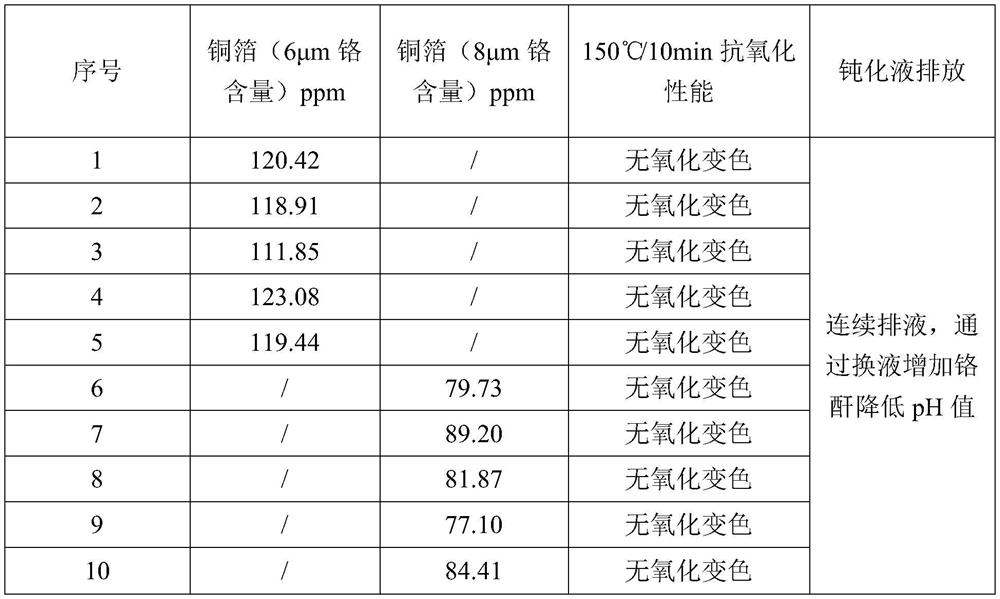

Embodiment 1

[0017] A passivation process of ultra-thin double-sided light lithium battery copper foil, comprising the following steps:

[0018] Step S1, surface treatment: clean up the dust and impurities on the surface of the copper foil, and rinse with clear water after cleaning;

[0019] Step S2, degreasing: Cleaning and degreasing with cleaning solution, the cleaning solution is mixed with sodium hydroxide, composite degreasing agent and deionized water according to the dosage ratio of 95g: 5mL: 100mL, and the composite degreasing agent includes three groups of A, B and C The A component is a mixture of phenol ethoxy phosphate potassium salt, nonylphenol polyoxyethylene ether and alkyl glycoside in a weight ratio of 2:1:2, and the B component is phenol ethoxylate Potassium phosphate ester, octylphenyl polyoxyethylene ether and alkyl glucoside are mixed according to the weight ratio of 2:1:2, and the C component is phenol ethoxy phosphate potassium salt, cardanol polyoxygen Vinyl ethe...

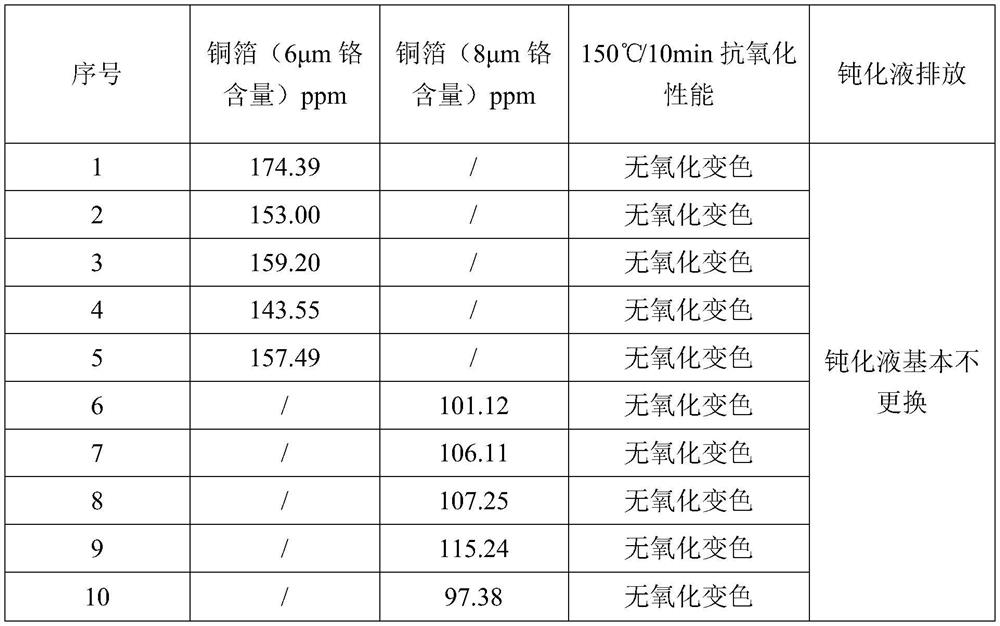

Embodiment 2

[0026] A passivation process of ultra-thin double-sided light lithium battery copper foil, comprising the following steps:

[0027] Step S1, surface treatment: clean up the dust and impurities on the surface of the copper foil, and rinse with clear water after cleaning;

[0028] Step S2, degreasing: Cleaning and degreasing with cleaning solution, the cleaning solution is mixed with sodium hydroxide, composite degreasing agent and deionized water according to the dosage ratio of 95g: 5mL: 100mL, and the composite degreasing agent includes three groups of A, B and C The A component is a mixture of phenol ethoxy phosphate potassium salt, nonylphenol polyoxyethylene ether and alkyl glycoside in a weight ratio of 2:1:2, and the B component is phenol ethoxylate Potassium phosphate ester, octylphenyl polyoxyethylene ether and alkyl glucoside are mixed according to the weight ratio of 2:1:2, and the C component is phenol ethoxy phosphate potassium salt, cardanol polyoxygen Vinyl ethe...

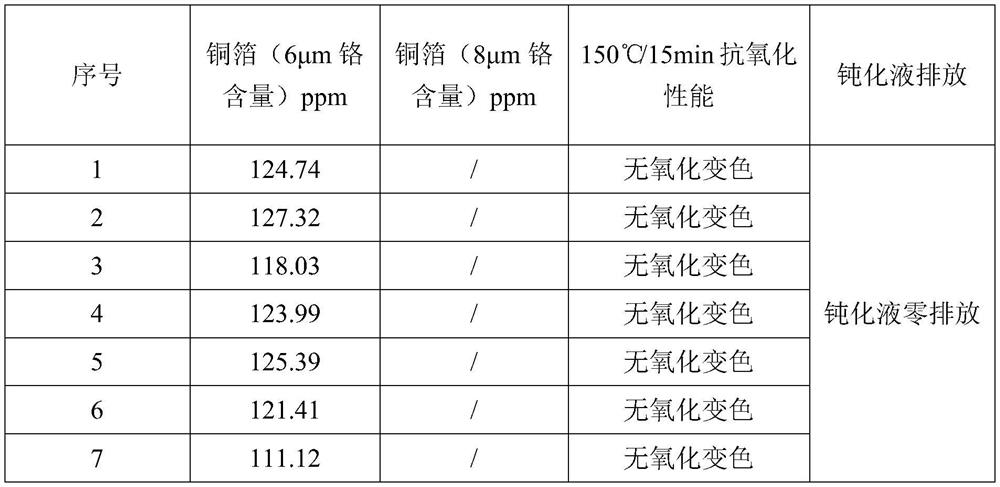

Embodiment 3

[0035] A passivation process of ultra-thin double-sided light lithium battery copper foil, comprising the following steps:

[0036] Step S1, surface treatment: clean up the dust and impurities on the surface of the copper foil, and rinse with clear water after cleaning;

[0037] Step S2, degreasing: Cleaning and degreasing with cleaning solution, the cleaning solution is mixed with sodium hydroxide, composite degreasing agent and deionized water according to the dosage ratio of 95g: 5mL: 100mL, and the composite degreasing agent includes three groups of A, B and C The A component is a mixture of phenol ethoxy phosphate potassium salt, nonylphenol polyoxyethylene ether and alkyl glycoside in a weight ratio of 2:1:2, and the B component is phenol ethoxylate Potassium phosphate ester, octylphenyl polyoxyethylene ether and alkyl glucoside are mixed according to the weight ratio of 2:1:2, and the C component is phenol ethoxy phosphate potassium salt, cardanol polyoxygen Vinyl ethe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com