Defective product analysis method and system for intelligent manufacturing

A technology of intelligent manufacturing and analysis methods, applied in manufacturing computing systems, image analysis, data processing applications, etc., to achieve the effect of improving efficiency, improving accuracy, and improving production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

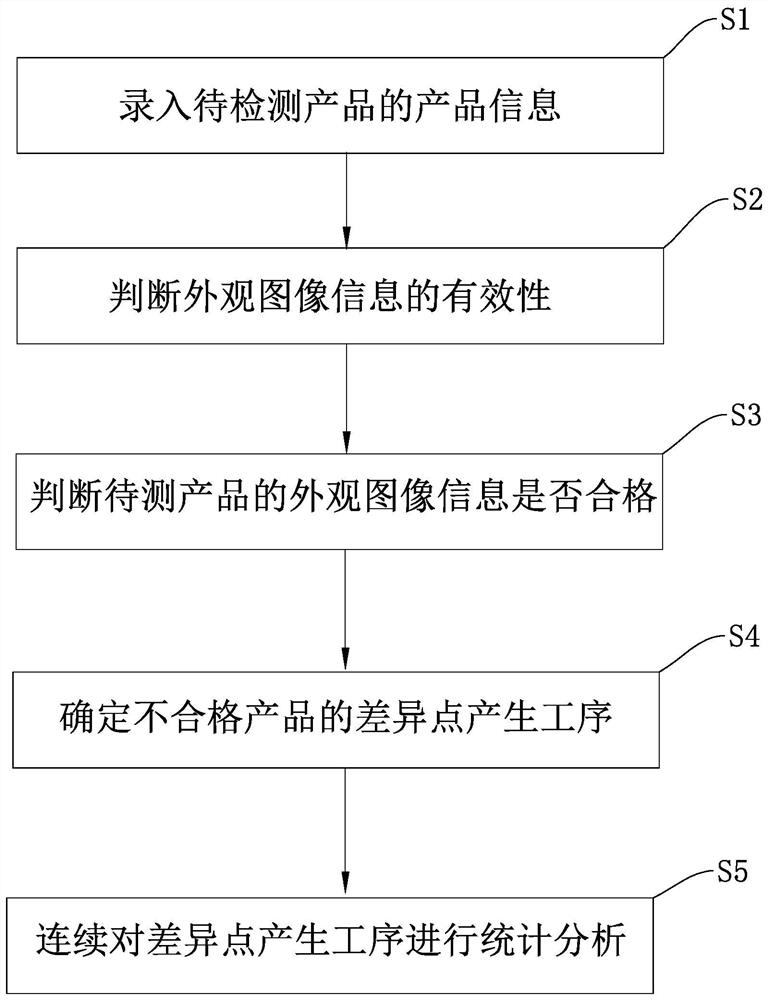

[0069] The following is attached Figure 1-7 The application is described in further detail.

[0070] The embodiment of the present application discloses a method for analyzing defective products for intelligent manufacturing. refer to figure 1 , a method for analyzing defective products for intelligent manufacturing, comprising the following steps:

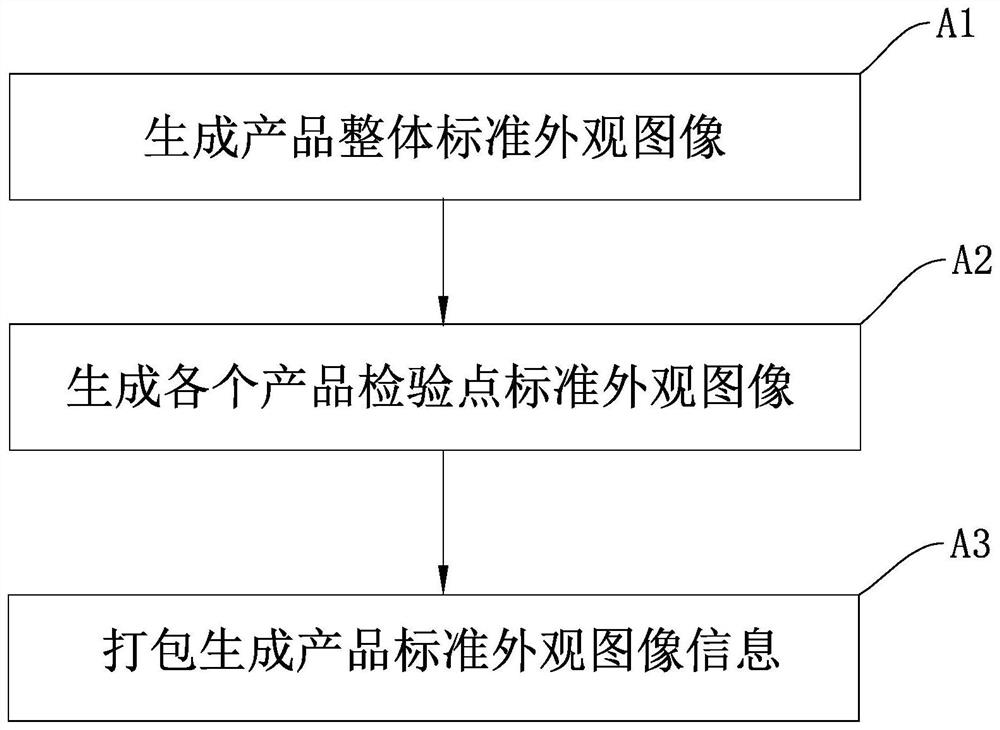

[0071] S1. Enter the product information of the product to be tested: establish a defective product inspection and analysis platform, and enter the product information of the product to be tested. The product information includes product name information, product type information, product standard appearance image information, product process information and product information. Inspection point information;

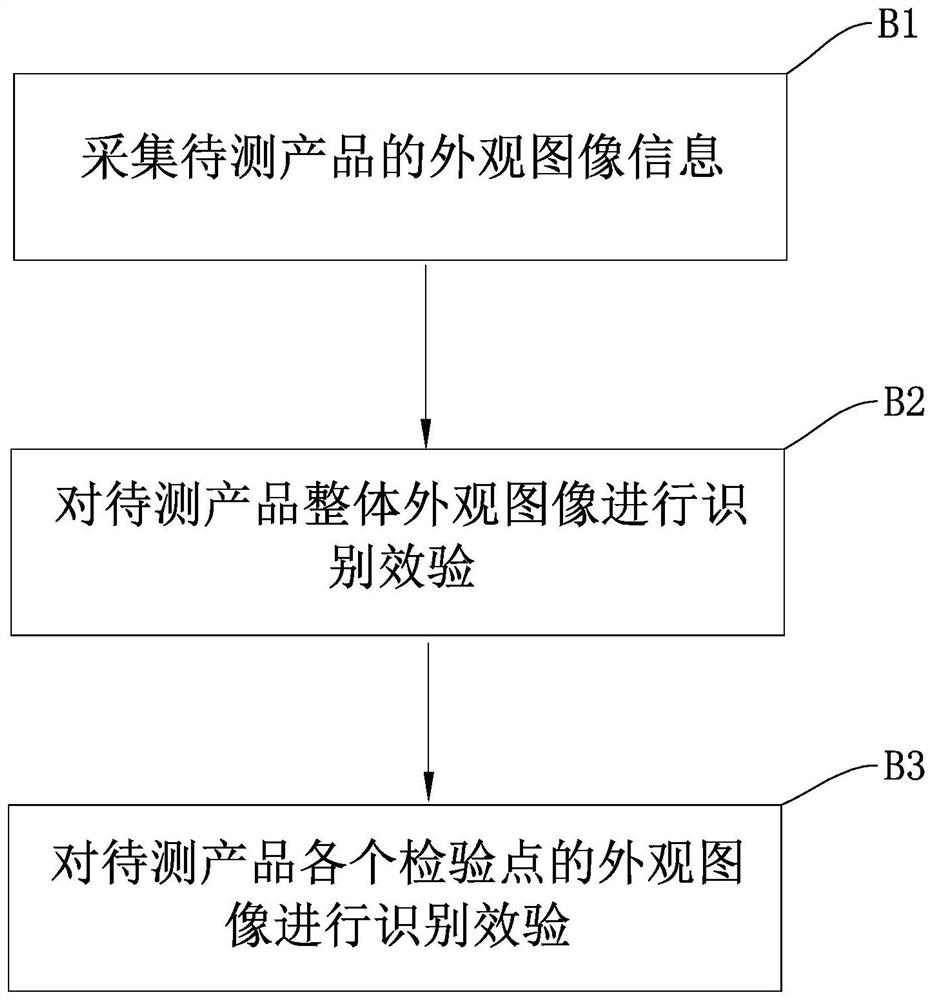

[0072] S2. Judging the validity of the appearance image information: obtaining the appearance image information of the product to be tested, performing preliminary identification on the acquired appearance image informat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com