Surface decoration method for 3D plate

A surface decoration and plate technology, applied in the field of 3D plate surface decoration, can solve the problems of high cost, unfavorable product production, hinder the development of 3D plate surface decoration technology, etc., and achieve the effect of easy operation, operability and cost improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

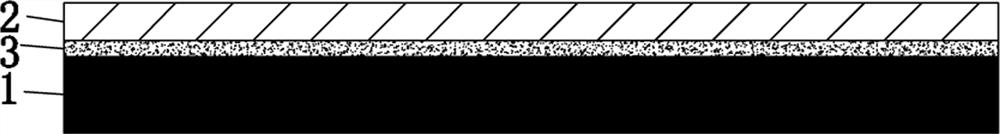

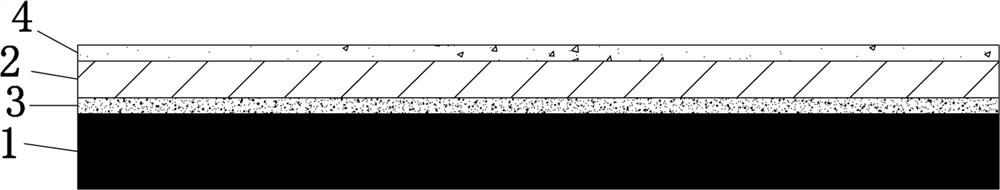

[0039] The present invention relates to a method for surface decoration of 3D boards. In the method, an inner texture layer 2 is provided on the surface of any 3D board 1 through secondary treatment, and the inner texture layer 2 is coated on any surface of the 3D board 1. a surface.

[0040] The method comprises the steps of:

[0041] Step 1: Determine the surface to be decorated of the 3D plate 1;

[0042] Step 2: Select the texture of the micro-nano structure, and wrap the membrane with the texture of the micro-nano structure on the outer edge of the surface to be decorated of the 3D plate 1 through secondary processing, which is the inner texture layer 2, and realize the surface decoration of the 3D plate 1.

[0043] In this embodiment, confirm the surface to be decorated of the 3D plate 1, select the texture of the micro-nano structure, rub it on the diaphragm through secondary processing, and wrap it on the outer edge of the surface to be decorated of the 3D plate 1, as...

Embodiment 2

[0045] On the basis of embodiment 1, said step 2 comprises the following steps:

[0046] Step 2.1: Select the texture of the micro-nano structure and attach it to the high-stretch film, and coat the 3D plate 1 with UV transfer printing glue;

[0047] Step 2.2: Attach the high-stretch film to the 3D plate 1 by vacuum to realize the primary treatment of micro-nano structure texture transfer;

[0048] Step 2.3: Use a hydraulic device to pressurize the high-stretch film on the 3D plate 1, remove the air bubbles between the high-stretch film and the 3D plate 1, and perform UV light curing in a vacuum state to realize the micro-nano structure texture Secondary processing of transfer printing;

[0049] Step 2.4: The high-stretch film forms an inner texture layer to realize the surface decoration of the 3D board 1 .

[0050] The pressure between the high-stretch membrane and the 3D plate 1 in step 2.3 is smaller than the pressure between the high-stretch membrane and the 3D plate 1 ...

Embodiment 3

[0057] On the basis of Example 1, between Step 1 and Step 2, a color layer 3 is coated between the surface to be decorated of the 3D plate 1 and the inner texture layer 2 .

[0058] In this embodiment, the color layer 3 is used to achieve different coloring effects.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com