A preparation method of transparent ceramic optical fiber based on isobam gel and melt spinning technology

A technology of transparent ceramics and melt spinning, applied in ceramic molding machines, rayon manufacturing, manufacturing tools, etc., can solve the problems of difficulty in mass production, opacity, easy to break, etc., to control the diameter of optical fibers, easy to scale The effect of production and operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

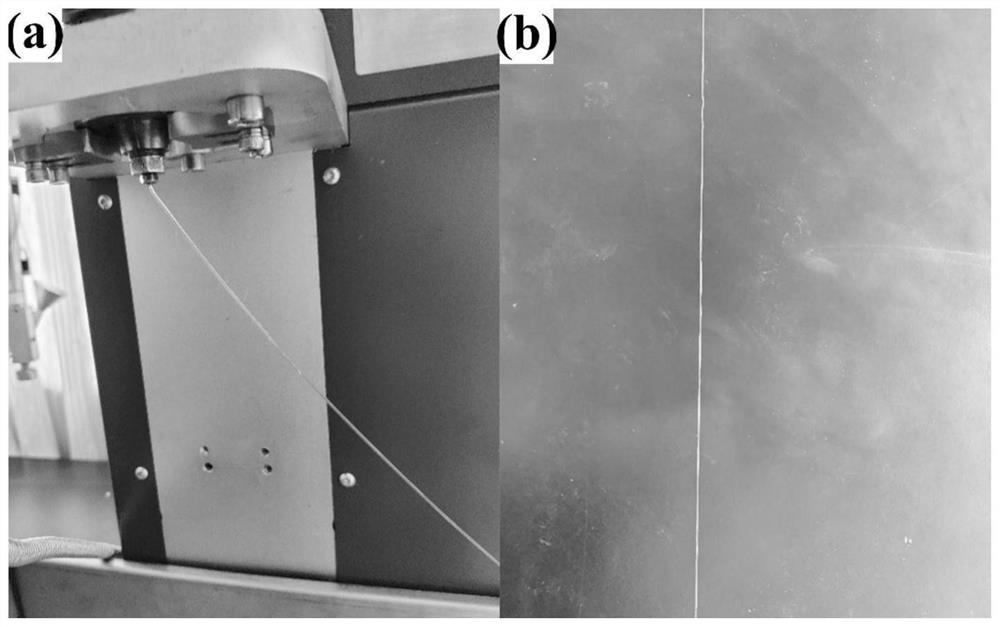

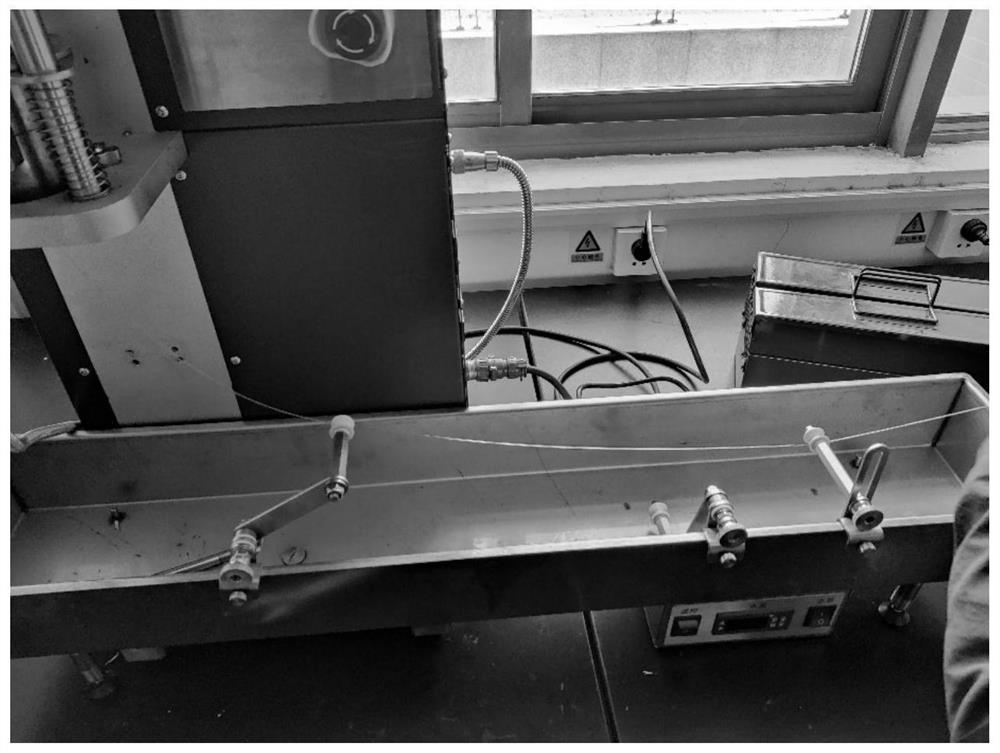

Image

Examples

Embodiment 1

[0031] A preparation method of Nd:YAG laser transparent ceramic optical fiber based on Isobam gel and melt spinning technology, comprising the following steps:

[0032] Step1. Weigh high-purity nano-Y according to the stoichiometric ratio of 1% Nd: YAG 2 O 3 Powder (purity>99.99%) 33.799 g, high-purity nano-Al 2 O 3 Powder (purity>99.99%) 25.692 g, high purity Nd 2 O 3 Powder (purity >99.99%) 0.509 g, pretreated for impurity removal.

[0033] Step2. Use sintering aid SiO 2 0.2 g for MgO and 0.1 g for MgO, high-purity Al 2 O 3 180 g of grinding balls and 72 ml of anhydrous ethanol were put into a ball-milling tank after being fully stirred, and the mixed slurry was obtained after mixing and ball-milling for 24 h uniformly.

[0034] Step 3. Put the mixed slurry in a constant temperature oven at 40 °C for 48 h and then sieve it. The sieved powder is calcined in a muffle furnace, heated from room temperature to 1000 °C, kept for 8 h and then cooled naturally. Raw material...

Embodiment 2

[0040] A method for preparing Nd:YAG laser transparent ceramic optical fiber based on Isobam gel and melt spinning technology, which comprises the following steps:

[0041] Step1. Weigh high-purity nano-Y according to the stoichiometric ratio of 4% Nd: YAG 2 O 3 Powder (purity>99.99%) 32.503g, high-purity nano-Al 2 O 3 Powder (purity>99.99%) 25.479 g, high purity Nd 2 O 3 Powder (purity>99.99%) 2.018g, pretreated for impurity removal.

[0042] Step2. Use sintering aid SiO 2 0.25 g for MgO and 0.05 g for MgO, high-purity Al 2 O 3 180 g of grinding balls and 72 ml of anhydrous ethanol were put into a ball-milling tank after being fully stirred, and the mixed slurry was obtained after mixing and ball-milling for 36 h.

[0043] Step3. Put the mixed slurry in a constant temperature oven at 100 °C for 24 h and then sieve it. The sieved powder is calcined in a muffle furnace, heated from room temperature to 800 °C, kept for 24 h and then cooled naturally. Raw material powder...

Embodiment 3

[0049] A method for preparing Nd:YAG laser transparent ceramic optical fiber based on Isobam gel and melt spinning technology, which comprises the following steps:

[0050] Step1. Weigh high-purity nano-Y according to the stoichiometric ratio of 2% Nd: YAG 2 O 3 Powder (purity>99.99%) 33.364g, high-purity nano-Al 2 O 3 Powder (purity>99.99%) 25.621 g, high-purity high-purity Nd 2 O 3 (purity >99.99%) 1.015g, pretreated for impurity removal.

[0051] Step2. Use sintering aid SiO 2 0.2 g and 0.1 g MgO, high-purity Al 2 O 3 180 g of grinding balls, 72 ml of anhydrous ethanol, fully stirred and put into a ball mill tank, mixed and milled for 30 h to obtain a mixed slurry.

[0052] Step 3. Put the mixed slurry in a constant temperature oven at 60 °C for 36 h and then sieve it. Put the sieved powder in a muffle furnace for calcination, heat it up from room temperature to 900 °C, keep it for 12 h and then cool it naturally. Raw material powder for plastic injection molding. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com