Reinforced cement prepared from aluminum ash regulator

A regulator and enhanced technology, applied in the field of cement materials, can solve problems such as alkali-aggregate reaction and large-volume cement cracks, and achieve the effects of enhanced strength, reduced final setting time, and good overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The enhanced cement prepared by using the aluminum ash regulator in this embodiment includes Portland cement clinker and auxiliary materials, and the mass ratio between the Portland cement clinker and the auxiliary materials is 1:0.3;

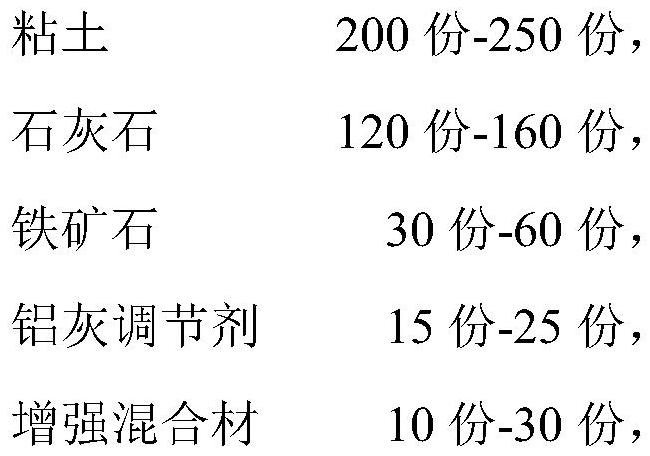

[0044] Described Portland cement clinker comprises the following raw materials in parts by weight:

[0045]

[0046] Wherein the reinforcing mixed material is a mixture of pyrite slag, copper slag and hydroxyethyl methyl cellulose ether, and the mass ratio between pyrite slag, copper slag and hydroxyethyl methyl cellulose ether is 4:5:17;

[0047] The auxiliary material is gypsum powder.

[0048] In the above-mentioned reinforced cement prepared by using the aluminum ash regulator, the average particle size of the clay is 8mm.

[0049] In the above-mentioned enhanced cement prepared by utilizing the aluminum ash regulator, the average particle diameter of the limestone is 10mm;

[0050] The average particle diameter of described ir...

Embodiment 2

[0063] The enhanced cement prepared by using the aluminum ash regulator in this embodiment includes Portland cement clinker and auxiliary materials, and the mass ratio between the Portland cement clinker and the auxiliary materials is 1:0.3;

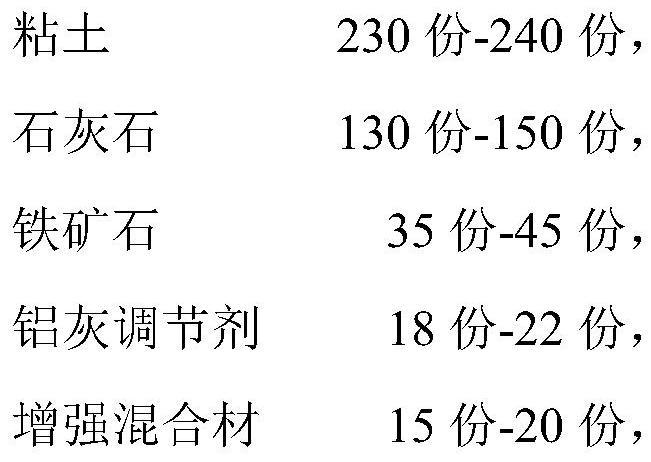

[0064] Described Portland cement clinker comprises the following raw materials in parts by weight:

[0065]

[0066] Wherein the reinforcing mixed material is a mixture of pyrite slag, copper slag and hydroxyethyl methyl cellulose ether, and the mass ratio between pyrite slag, copper slag and hydroxyethyl methyl cellulose ether is 4:5:17;

[0067] The auxiliary material is gypsum powder.

[0068] In the above-mentioned reinforced cement prepared by using the aluminum ash regulator, the average particle size of the clay is 8mm.

[0069] In the above-mentioned enhanced cement prepared by utilizing the aluminum ash regulator, the average particle diameter of the limestone is 10mm;

[0070] The average particle diameter of described ir...

Embodiment 3

[0083] The enhanced cement prepared by using the aluminum ash regulator in this embodiment includes Portland cement clinker and auxiliary materials, and the mass ratio between the Portland cement clinker and the auxiliary materials is 1:0.3;

[0084] Described Portland cement clinker comprises the following raw materials in parts by weight:

[0085]

[0086] Wherein the reinforcing mixed material is a mixture of pyrite slag, copper slag and hydroxyethyl methyl cellulose ether, and the mass ratio between pyrite slag, copper slag and hydroxyethyl methyl cellulose ether is 4:5:17;

[0087] The auxiliary material is gypsum powder.

[0088] In the above-mentioned reinforced cement prepared by using the aluminum ash regulator, the average particle size of the clay is 8mm.

[0089] In the above-mentioned enhanced cement prepared by utilizing the aluminum ash regulator, the average particle diameter of the limestone is 10mm;

[0090] The average particle diameter of described ir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com