Calcium chloride hexahydrate composite phase change thermal insulation mortar

A technology of calcium chloride hexahydrate and thermal insulation mortar, which is applied in the field of building materials and can solve problems such as small enthalpy change, supercooling, and phase separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A composite phase change thermal insulation mortar containing calcium chloride hexahydrate, including mortar, the phase change energy storage material is 20wt%, the calcium chloride hexahydrate: strontium chloride hexahydrate: sodium carboxymethyl cellulose The ratio in parts by weight is 87:10:3.

Embodiment 2

[0031] A composite phase change thermal insulation mortar containing calcium chloride hexahydrate, including mortar, the phase change energy storage material is 30wt%, the calcium chloride hexahydrate: strontium chloride hexahydrate: sodium carboxymethyl cellulose The ratio in parts by weight is 85:10:5.

Embodiment 3

[0033] A composite phase change thermal insulation mortar containing calcium chloride hexahydrate, including mortar, the phase change energy storage material is 5wt%, the calcium chloride hexahydrate: strontium chloride hexahydrate: sodium carboxymethyl cellulose The ratio in parts by weight is 98:1:1.

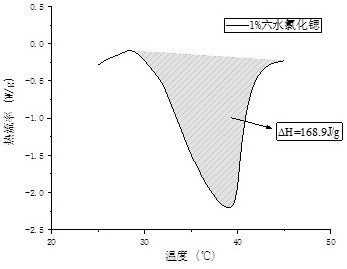

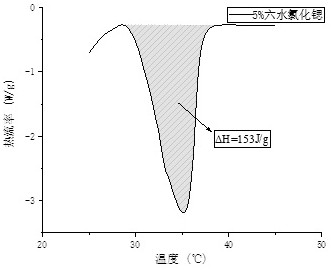

[0034] Effects of different nucleating agents on the properties of phase change energy storage materials

[0035] Example 1 Nucleating agent strontium chloride hexahydrate

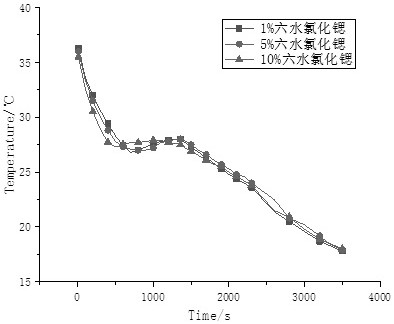

[0036] Step 1, sample preparation: in a constant temperature environment of 35 degrees, three parts of calcium chloride hexahydrate with a mass of 10g were respectively added to the three groups of calcium chloride hexahydrate with a weight fraction of 1%, 5%, and 10%. The nucleating agent strontium chloride hexahydrate forms a mixture. After stirring evenly, the mixture is left to stand and kept warm until the temperature is stable, and then the mixture is quickly transferred to a water bath environment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com