Binding method of graphite rotating target material

A technology of rotating target and graphite, which is applied in metal material coating process, ion implantation plating, coating, etc., can solve the problems of uniformity and quality control of binding, high requirements for staff operation, complex structure, etc. Achieve the effects of avoiding high temperature burns, concentricity and clearance convenience, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

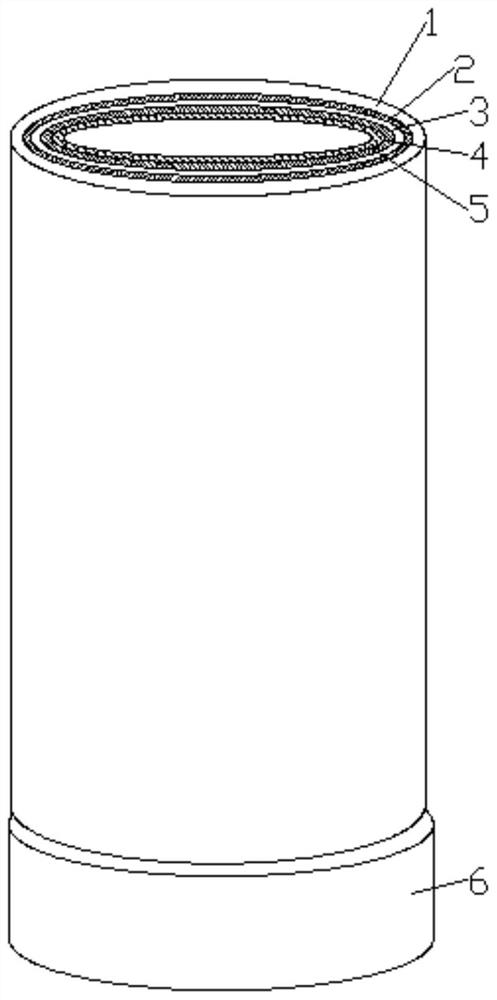

[0027] A binding method of a graphite rotating target, from 304 stainless steel pipe 5, the target is a graphite tube target 1, and the binding device employed is a rotary table 6, first complete the liner of graphite paper and copper web combination 3. Bind, complete the binding of the graphite tube target.

[0028] Completed according to the following steps figure 1 The target binding: a stainless steel tube having a length of 1000 mm and an outer diameter of 80 mm is used as a liner, and it is fixed to the rotating table 6.

[0029] The liner coating: the rotating table 6 revolution is maintained at 14R / min, and a layer of thermally conductive rubber 2 4 is uniformly applied in the outer wall of the stainless steel liner 5.

[0030] Lining tube binding: a graphite paper having a thickness of 0.3 mm, graphite paper size can take the liner to be covered; put a 80 destination copper net onto the graphite paper; uniformly coated on the copper Layer-free thermal adhesive 2 4, cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com