Preparation method of amorphous carbon film

An amorphous carbon film and substrate technology, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve problems such as inability to effectively filter out blue light and difficulty in protecting human eyes, and reduce eye discomfort Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A kind of preparation of amorphous carbon film:

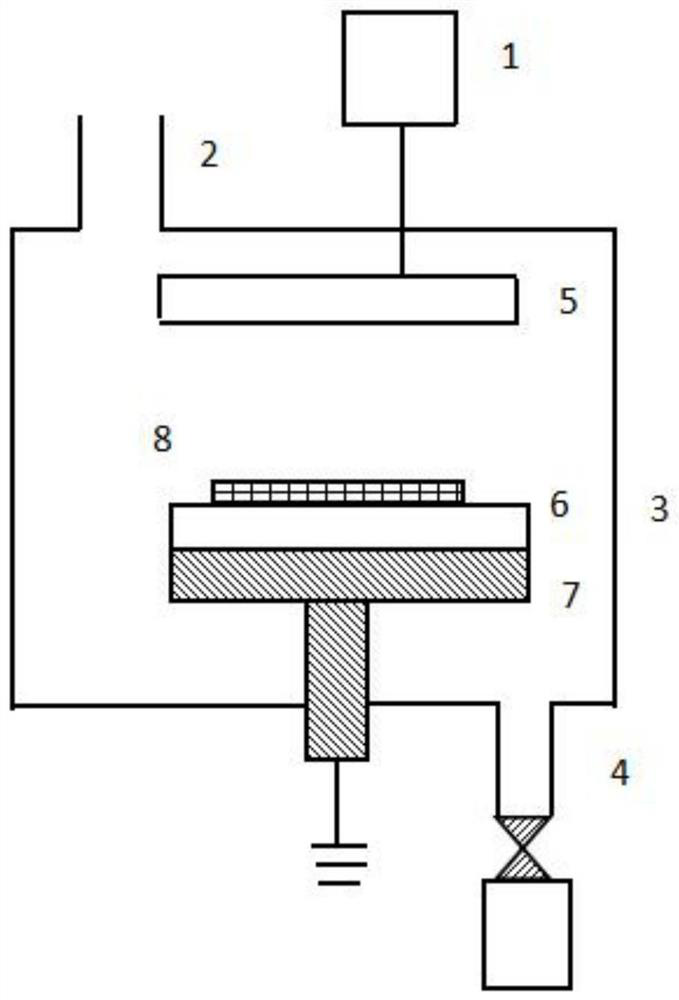

[0022] Place the 2mm thick glass slide substrate in RF-PECVD equipment (such as figure 1 (shown) on the lower electrode plate in the reaction chamber, turn on the vacuum pump, evacuate the reaction chamber to a pressure of 0.8 Torr, heat the substrate to 50°C, and then flow the precursor gas from the air inlet at a flow rate of 20 sccm and 20 sccm Mix benzonitrile and VSZ, use 10 sccm argon as the carrier gas, and perform vapor deposition on the carrier slide under the power of the radio frequency generator of 50W to obtain an amorphous carbon film with anti-blue light.

Embodiment 2

[0024] A kind of preparation of amorphous carbon film:

[0025] Place the 2mm thick glass slide substrate in RF-PECVD equipment (such as figure 1 (shown) on the lower electrode plate in the reaction chamber, turn on the vacuum pump, evacuate the reaction chamber to a pressure of 0.8Torr, heat the substrate to 120°C, and then flow the precursor gas from the air inlet at a flow rate of 20sccm and 20sccm Mix benzonitrile and VSZ, use 10sccm argon as the carrier gas, and perform vapor deposition on a glass slide under the power of a radio frequency generator of 50W to obtain a blue-reflective amorphous carbon film.

Embodiment 3

[0027] A kind of preparation of amorphous carbon film:

[0028] Place the 2mm thick glass slide substrate in RF-PECVD equipment (such as figure 1 (shown) on the lower electrode plate in the reaction chamber, turn on the vacuum pump, evacuate the reaction chamber to a pressure of 0.8Torr, heat the substrate to 200°C, and then flow the precursor gas from the air inlet at a flow rate of 20sccm and 20sccm Mix benzonitrile and VSZ, use 10sccm argon as the carrier gas, and perform vapor deposition on a glass slide under the power of a radio frequency generator of 50W to obtain a blue-reflective amorphous carbon film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com