Rotary machinery vibration integrated management system

A technology of rotating machinery and comprehensive management, applied in the field of rotating machinery systems, can solve the problems of automatic deletion, economic loss, affecting unit safety, etc., and achieve the effect of improving the level of comprehensive management, improving work efficiency, and saving storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

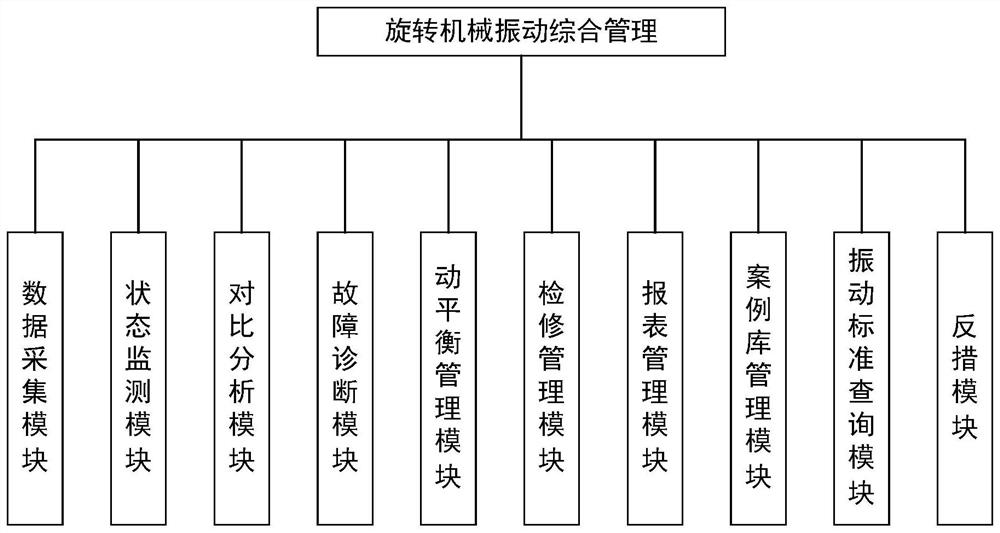

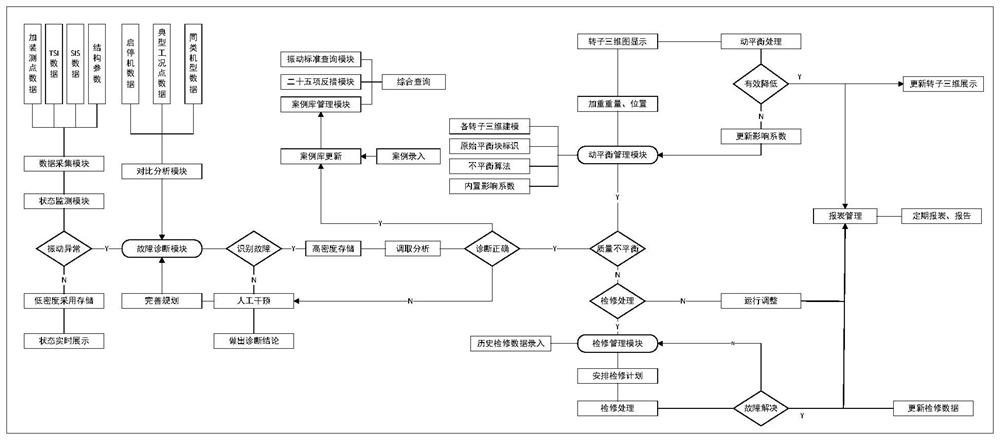

[0038] like figure 1 and figure 2 As shown, this embodiment provides a comprehensive vibration management system for rotating machinery, including:

[0039] The data acquisition module is used to collect vibration signals of rotating machinery (the vibration signals of the steam turbine are imported from the TSI system, and the vibration signals of the auxiliary machines are transmitted to the switchboard by the acceleration sensor installed on site), and the parameters of the thermal system (load, main steam pressure, etc.) are imported from the SIS , current, valve opening, bearing temperature, vacuum, etc.), and the structural parameters of each rotating machine;

[0040]The status monitoring module is used to monitor whether the vibration of the rotating equipment is abnormal. If the vibration signal is normal, it will store the vibration signal in low density and display the normal vibration parameters in real time. If the vibration signal is abnormal, it will go to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com