High performance liquid chromatography for measuring content of sec-butylamine

A technology of high performance liquid chromatography and sec-butylamine, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of high cost, harsh processing requirements, complicated operation, etc., and achieve the effect of low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A high-performance liquid chromatography method for determining the content of sec-butylamine

[0016] Weigh 0.1g of iodine, dissolve it in 100mL of methanol, and dilute to 1000mL with water to prepare a 0.01% iodine solution with a flow rate of 0.3ml / min. The sec-butylamine solution to be tested was introduced into a high-performance liquid chromatograph through an autosampler, separated by a C18 chromatographic column, derivatized with an iodine solution at 60°C, and then measured at an ultraviolet wavelength of 270nm.

Embodiment 2

[0018] A high-performance liquid chromatography method for determining the content of sec-butylamine

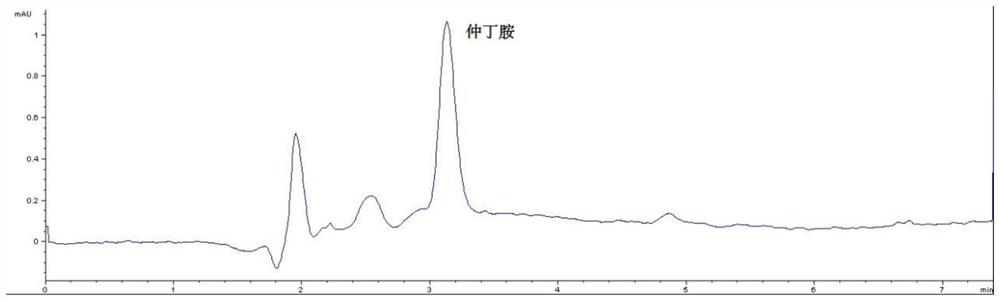

[0019] Weigh 0.3g of iodine, dissolve it in 100mL of methanol, and dilute to 1000mL with water to prepare a 0.03% iodine solution with a flow rate of 0.3ml / min. The sec-butylamine solution to be tested was introduced into the high performance liquid chromatography through an autosampler, separated by a C18 chromatographic column, derivatized with an iodine solution at 70°C, and then measured at an ultraviolet wavelength of 280nm. For details, see figure 1 ,according to figure 1 It can be seen that the peak at about 3.2 min is the chromatographic peak derived from sec-butylamine.

Embodiment 3

[0021] A high-performance liquid chromatography method for determining the content of sec-butylamine

[0022] Weigh 0.5g of iodine, dissolve it with 100mL of methanol, and dilute to 1000mL with water to prepare a 0.05% iodine solution with a flow rate of 0.3ml / min. The sec-butylamine solution to be tested was introduced into a high-performance liquid chromatograph through an autosampler, separated by a C18 chromatographic column, derivatized with an iodine solution at 80°C, and then measured at an ultraviolet wavelength of 330nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com