Method for prolonging service life of silicon carbide epitaxial wafer carrier

A carrier lifetime and epitaxial wafer technology, applied in gaseous chemical plating, coatings, electrical components, etc., can solve the problems of low carrier lifetime, inability to achieve conductance modulation, etc., to improve carrier lifetime, carbon The effect of vacancy suppression and optimized design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

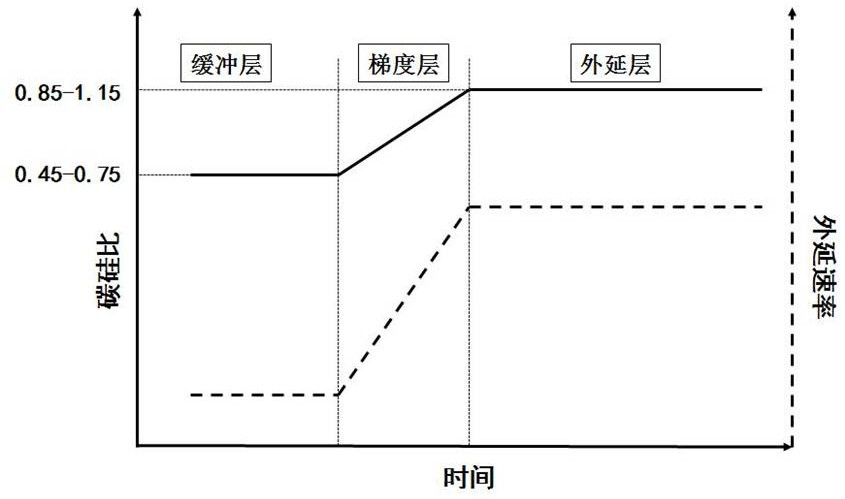

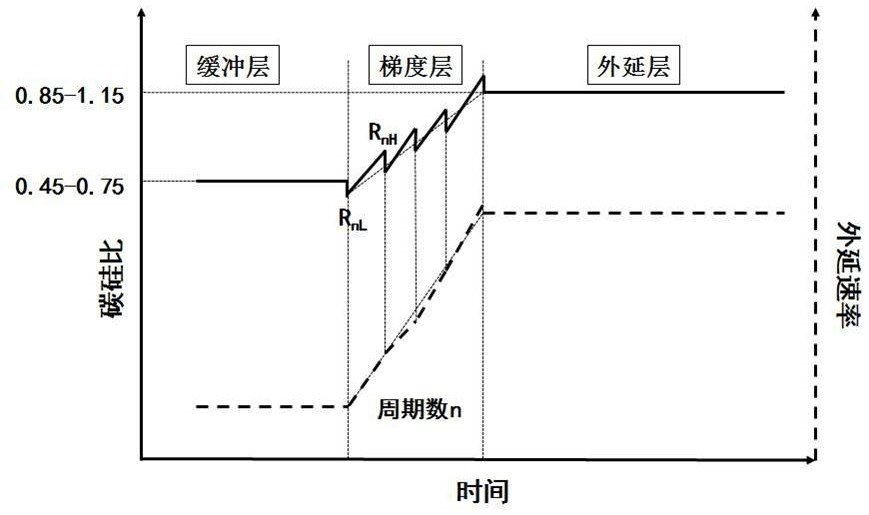

Method used

Image

Examples

Embodiment 1

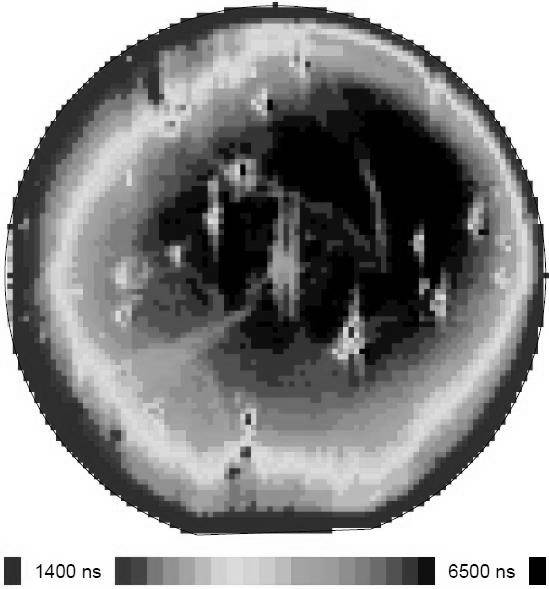

[0039] Provided in the SiC chemical vapor deposition epitaxy system, using a method of improving the carrier lifetime of silicon carbide epitaxial wafers by optimizing the gradient layer structure, the method for growing epitaxial materials with a withstand voltage of 15kV IGBT structure includes the following steps:

[0040] S1. Select a silicon carbide substrate with a silicon surface that is 4° to the direction, and place the cleaned substrate on the graphite base in the reaction chamber of the SiC epitaxy system.

[0041] S2. Use argon to replace the gas in the reaction chamber, use argon as the flotation gas to drive the graphite base to rotate, turn on the hydrogen switch leading to the reaction chamber, control the pressure of the reaction chamber to gradually increase to 100mbar, and control the flow of hydrogen to gradually increase As large as 100L / min, the reaction chamber is gradually heated to the growth temperature of 1650°C, and the temperature of the reaction c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| charge carrier lifetime | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com