Puffed soybean for feed and preparation method thereof

A technology for puffing soybeans and soybeans, which is applied in the directions of animal feed, animal feed, and application, can solve the problems of reducing the content of anti-nutritional factors of puffed soybeans and high anti-nutritional factors of puffed soybeans, so as to be conducive to absorption and growth, and reduce anti-nutritional factors. The effect of the content of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The present invention provides a kind of preparation method of puffed soybean for feed on the one hand, and this method comprises the following steps:

[0022] (1) pulverizing the soybean raw material after removing iron and impurities;

[0023] (2) sending the pulverized soybean material obtained in step (1) into a microwave puffing machine for microwave puffing;

[0024] (3) The soybean raw material after the microwave puffing that step (2) obtains is directly imported in the insulation tank and stirred and kept warm, and the holding time is 90-120min;

[0025] (4) Take out the puffed soybean after step (3) heat preservation, cool and pulverize.

[0026] In the present invention, in the step (1), the equipment for the iron removal operation can be conventionally selected in the field. Preferably, the iron removal is carried out in a magnetic rolling barrel.

[0027] In the present invention, in step (1), the equipment for the impurity removal operation can be conve...

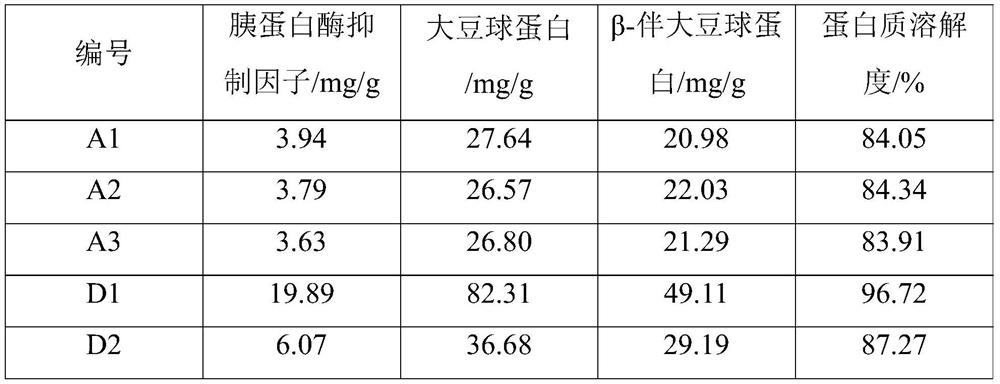

Embodiment 1

[0040] (1) The soybean raw material after removing iron and impurities is crushed to an average particle size of 3 mm, wherein the operation of iron removal is carried out in a rolling magnetic bucket, and the operation of removing impurities is carried out in a vibrating sieve;

[0041] (2) Send the crushed soybean material obtained in step (1) into a microwave puffing machine for microwave puffing. The absolute pressure of microwave puffing is 0.55MPa, the temperature of microwave puffing is 85°C, and the power of microwave puffing is 550W. The puffing time is 70s;

[0042] (3) The soybean raw material after the microwave puffing that step (2) obtains is directly imported in the heat preservation tank and stirred and kept warm, and the heat preservation time is 120min;

[0043] (4) Taking out the extruded soybean after heat preservation in step (3), cooling and pulverizing to obtain the extruded soybean A1 for feed.

Embodiment 2

[0045] (1) Grinding the soybean raw material after removing iron and impurities to an average particle size of 4mm, wherein the operation of iron removal is carried out in a rolling magnetic barrel, and the operation of removing impurities is carried out in a vibrating sieve;

[0046] (2) Send the crushed soybean material obtained in step (1) into a microwave puffing machine for microwave puffing. The absolute pressure of microwave puffing is 0.7MPa, the temperature of microwave puffing is 95°C, and the power of microwave puffing is 650W. The puffing time is 60s;

[0047] (3) The soybean raw material after the microwave puffing that step (2) obtains is directly imported in the heat preservation tank and stirred and kept warm, and the heat preservation time is 90min;

[0048] (4) Taking out the extruded soybean after heat preservation in step (3), cooling and pulverizing to obtain the extruded soybean A2 for feed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com