Water-saving method for pretreatment in water treatment process

A pretreatment and water treatment technology, applied in water/sewage treatment, water treatment parameter control, water/sewage multi-stage treatment, etc., can solve the problems of filter failure, filter material saturation or hardening, and height not exceeding 50μm, etc. To achieve the effect of reducing the consumption of raw water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

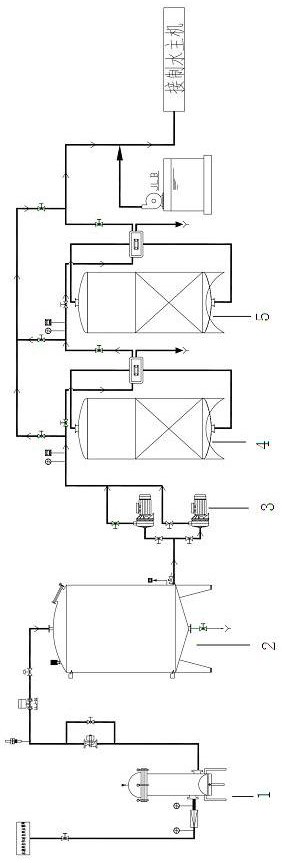

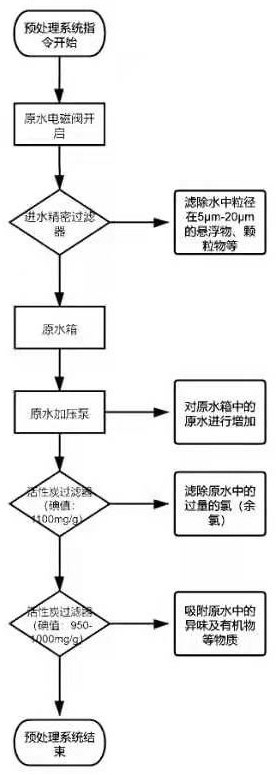

[0020] Refer to attached figure 1 , 2 , a water-saving method for pretreatment in a water treatment process,

[0021] (a) The equipment included in the pretreatment process is as follows:

[0022] 1) Precision filter 1: Precision filter (also known as security filter), the shell of the cylinder is made of SUS304 stainless steel, and the interior uses tubular filter elements such as PP melt-blown and folded filter elements as filter elements. According to different filter media and designs The process selects different filter elements to meet the requirements of effluent water quality.

[0023] 2) Raw water tank 2: It is a temporary storage container for raw water, which plays a role in regulating and storing the subsequent membrane treatment process.

[0024] 3) Raw water pump 3: pressurized water pump for raw water, which pressurizes the water source in the raw water tank and sends it to the subsequent filter.

[0025] 4) Activated carbon filter filled with iodine value ≥...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com