Special master batch for foamed polypropylene with high light oxygen stability and preparation method of special master batch

A technology of foaming polypropylene and stability, which is applied in the field of manufacturing foamed polypropylene special masterbatches to achieve the effects of improving dispersion and processability, improving the working environment of the workshop, and reducing processing difficulty and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

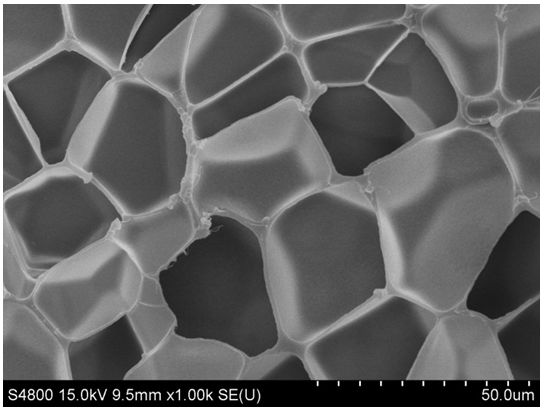

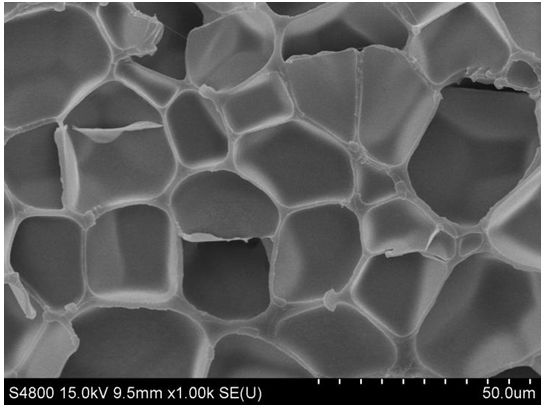

Image

Examples

Embodiment 1

[0024] Special masterbatch for foamed polypropylene with high photo-oxygen stability:

[0025] Polypropylene 57wt%;

[0026] HALS-2020 30wt%;

[0028] Antioxidant 168 2wt%;

[0030] The mass percentages mentioned above are the percentages of the total mass.

[0031] According to the above percentage by weight, mix HALS-2020 with zinc oxide, then add to a high-speed mixer to neutralize antioxidant 168 and zinc stearate and mix at room temperature for 5-8 minutes at a speed of 40rpm to obtain a premix, which is finally measured by The pump and polypropylene are fed into the twin-screw extruder at 220 o C. Extrude and granulate, and dry to obtain a special masterbatch for foamed polypropylene with high light and oxygen stability, that is, an anti-aging masterbatch.

[0032] 10% of the anti-aging masterbatch obtained (accounting for the total mass) is added to the twin-screw extruder with polypropylene resin and foaming...

Embodiment 2

[0039] According to the scheme of Example 1, on the basis of Example 1, the addition amount and compounding ratio of the light stabilizer and light shielding agent were changed to prepare a special anti-aging masterbatch for light-oxygen stabilized polypropylene foam:

[0040] Polypropylene 87wt%;

[0041] HALS-2020 5wt%;

[0043] Antioxidant 168 2wt%;

[0044] Zinc stearate 1wt%;

[0045] The mass percentages mentioned above are the percentages of the total mass.

[0046] The preparation method and detection method of the special masterbatch for high photo-oxygen stability foamed polypropylene described in the present invention are the same as those in Example 1.

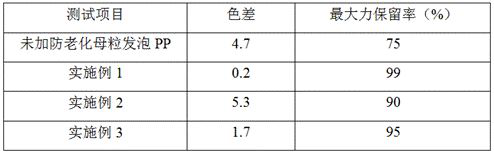

[0047] Tensile test: test according to GB / T 1040.5-2006; test results are shown in Table 1.

[0048] The results show that the surface of the product containing the special masterbatch of the present invention is not pulverized and does not fade, and the maximum force retention rate a...

Embodiment 3

[0050]According to the scheme of Example 1, on the basis of Example 1, the addition amount and compounding ratio of the light stabilizer and light shielding agent were changed to prepare a special anti-aging masterbatch for light oxygen stabilized polypropylene foam:

[0051] Polypropylene 72wt%;

[0052] HALS-2020 15wt%;

[0053] Zinc oxide 10wt%;

[0054] Antioxidant 168 2wt%;

[0055] Zinc stearate 1wt%;

[0056] The mass percentages mentioned above are the percentages of the total mass.

[0057] The preparation method and detection method of the special masterbatch for high photo-oxygen stability foamed polypropylene described in the present invention are the same as those in Example 1.

[0058] Tensile test: test according to GB / T 1040.5-2006; test results are shown in Table 1.

[0059] The results show that the surface of the product containing the special masterbatch of the present invention is not pulverized and does not fade, and the maximum force retention rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com