Glass fiber reinforced polyamide material for plastic high-pressure water gun and preparation method

A high-pressure water gun and polyamide technology, which is applied in the field of glass fiber reinforced polyamide materials and preparation, can solve the problems of material rigidity reduction and pressure resistance reduction, and achieve good bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

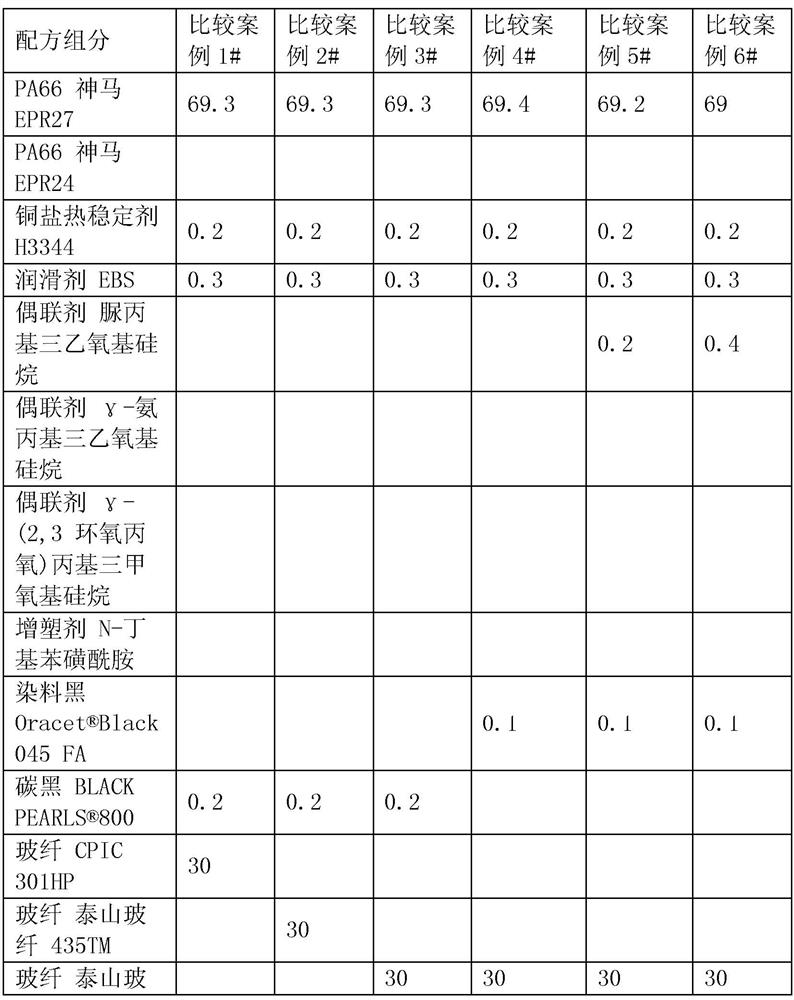

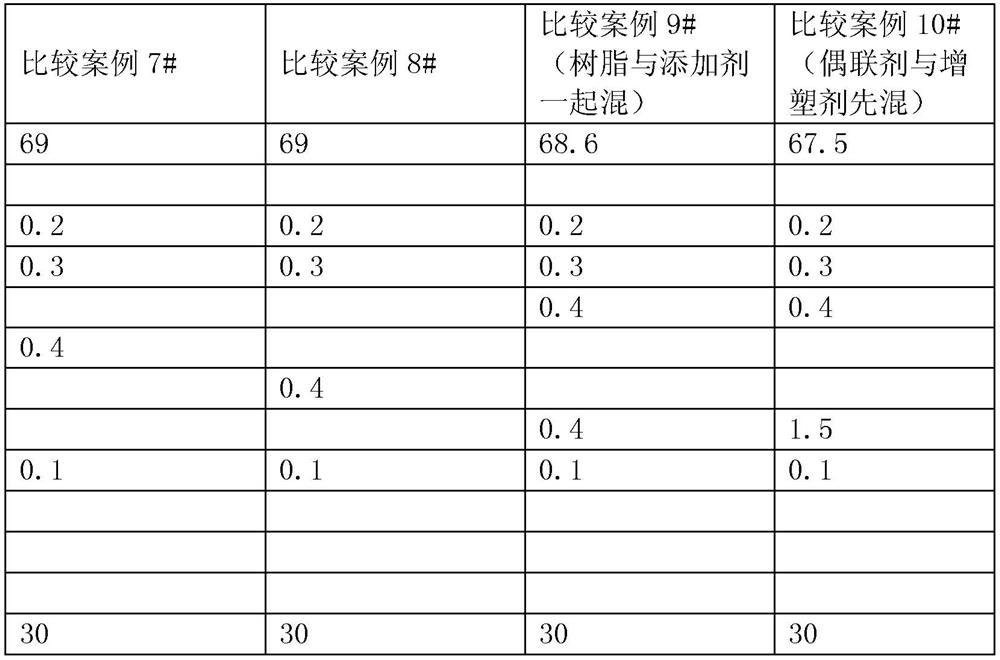

Method used

Image

Examples

example 1

[0070] The present invention also carries out improved treatment to glass fiber in embodiment case 1; Concrete modification method is:

[0071] S1, mixing and hybridizing glass fiber and wollastonite according to a weight ratio of 3:2 to obtain a hybrid material; the length of the glass fiber is 1 nm; the length of the wollastonite is 1 nm;

[0072] S2, reacting 60 parts of polyether diol with a molecular weight of 1000 and 10 parts of diphenylmethane diisocyanate at 80° C. for 1 hour to obtain a polyurethane prepolymer;

[0073] S3, add 2 times of xylene to the polyurethane prepolymer, then add 1% of dimethyl tin dilaurate in the total amount of polyurethane prepolymer, and then add 2% of silane coupling agent KH560, at 70 ° C , stirred at a rotating speed of 400r / min for 45min, and the stirring was completed to obtain a contact modification liquid;

[0074] S4, send the hybrid material into 4 times the contact modification solution for stirring reaction treatment, the stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com