Abrasive material, processing equipment and processing technology thereof

A technology of processing equipment and abrasives, applied in metal processing equipment, grinding/polishing equipment, metal processing and other directions, can solve the problems of limited edges and corners, reduce the processing effect and cutting of the workpiece to be processed, and achieve cost and labor saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

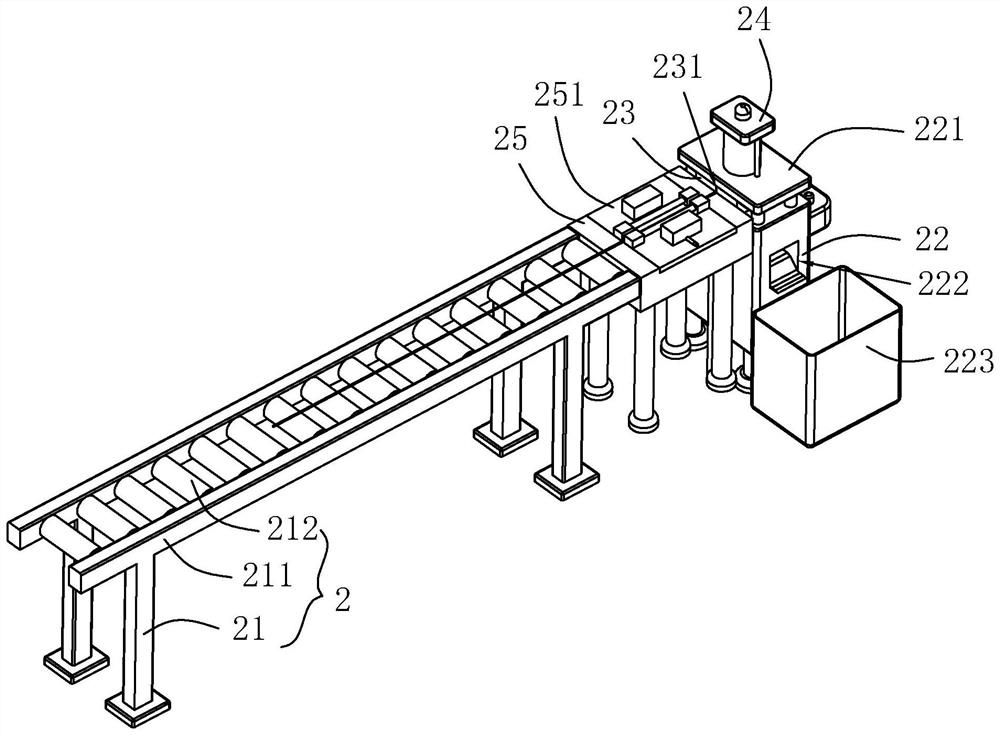

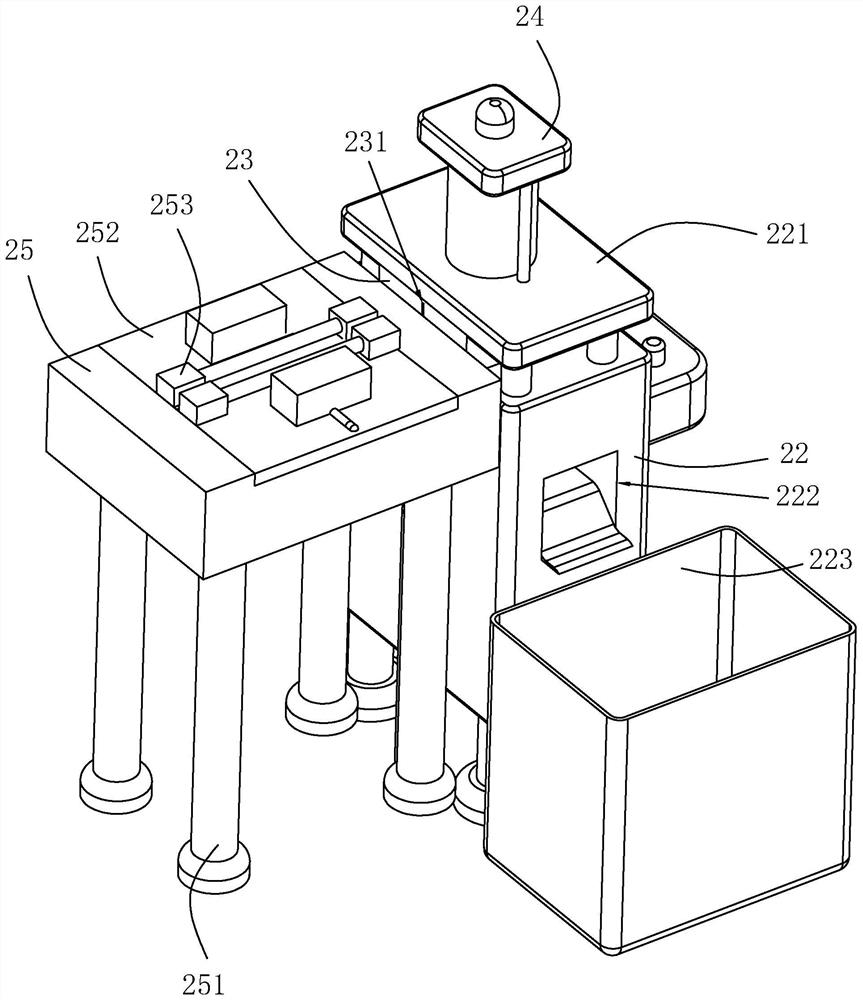

[0038] The following is attached Figure 1-4 The application is described in further detail.

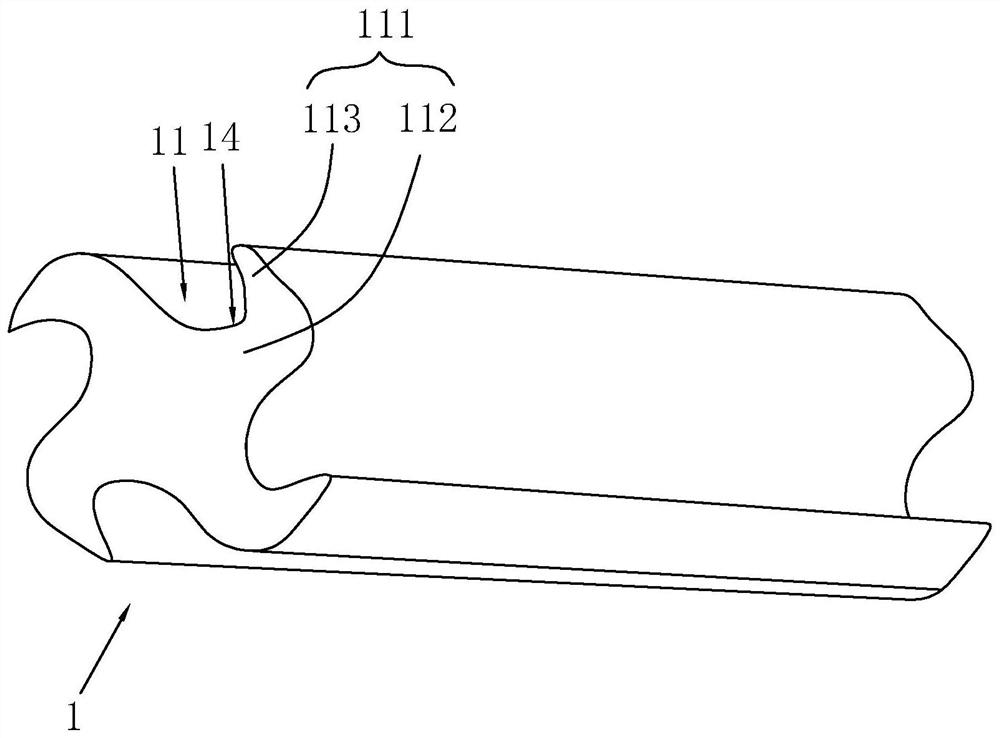

[0039] The embodiment of the present application discloses a grinding material. refer to figure 1 , a kind of grinding material, comprises grinding body 1, and grinding body 1 is set to the metal body that metal material is made, and in the present embodiment, grinding body 1 is set to the metal body that 304 stainless steel is made, and the diameter of grinding body 1 is 1.2mm-5mm, it can be adjusted adaptively according to the workpiece to be processed.

[0040] Such as figure 1 As shown, a plurality of grinding grooves 11 are provided on the grinding body 1 along the circumferential position of the grinding body 1, and the two ends of the grinding grooves 11 penetrate the grinding body 1 and are arranged, and the grinding body 1 is divided by a plurality of grinding grooves 11 to form a plurality of grinding parts 111 , in this embodiment, four grinding tanks 11 are provided, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap