Automatic transportation system for medical fabric washing

An automatic transportation and fabric technology, applied in the field of fabric processing, can solve the problems of increasing the limitation and inconvenience of fabric automation production, reducing the work efficiency of fabric washing, and the large manpower demand of staff, so as to increase the efficiency of fabric automation transportation and increase convenience , speed up the transport rhythm and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

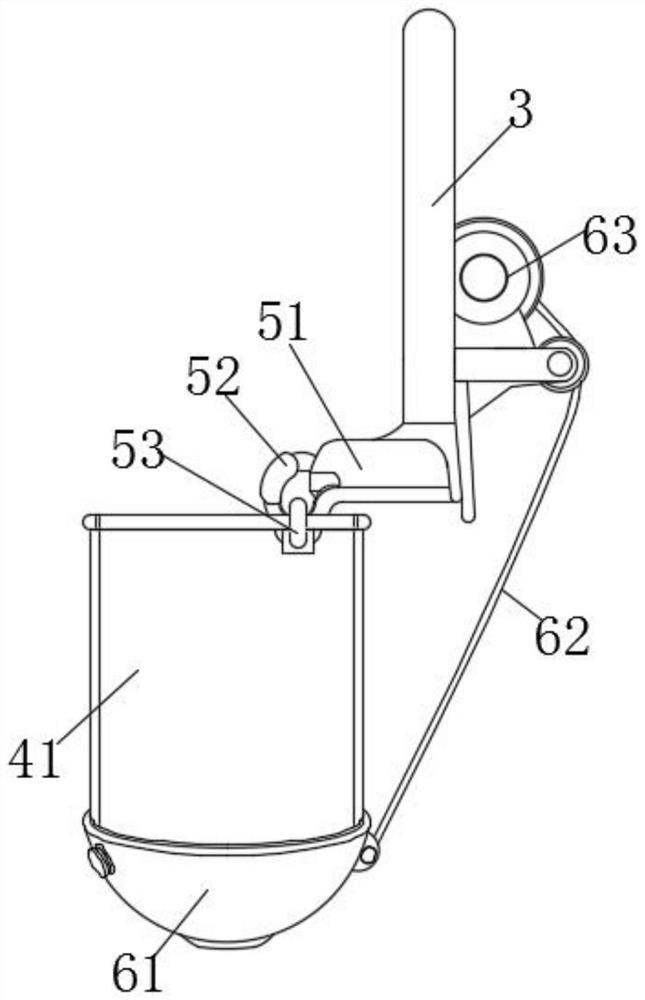

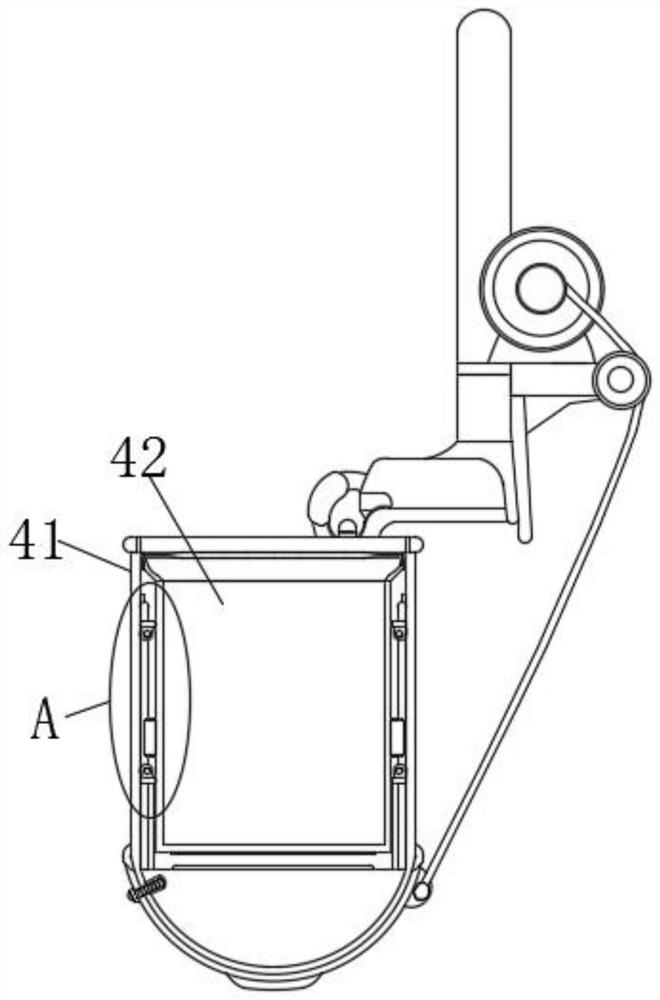

[0036] Example 1, such as Figure 1-3 As shown, when the cylinder body 41 needs to be disassembled and cleaned, the positioning hanging rings 53 and the elastic buckles 52 at the top ends of the cylinder body 41 can be canceled and positioned, and then the external fixing bolts of the tapered frame 61 and the cylinder body 41 can be canceled. With the fixing of the inner threaded hole of the lower tapered plate, the cylinder body 41 can be dismantled separately at this time, and the storage barrel 42 can be cleaned and maintained to increase the convenience of disassembly and assembly of the structure.

Embodiment 2

[0037] Example 2, such as Figure 1-3 As shown, using the conical structure of the conical frame 61 and the automatic splicing and positioning with the cylinder body 41, a balance bracket is obtained under the cylinder body 41, and two sets of elastic buckles 52 and positioning hanging rings 53 are used to cooperate with the structure of the balance bracket , it can provide the overall stability of the cylinder 41, and promote the balance of the cylinder 41 during the suspension conveying, so as to avoid tilting and shaking, which may cause the inner fabric to fall.

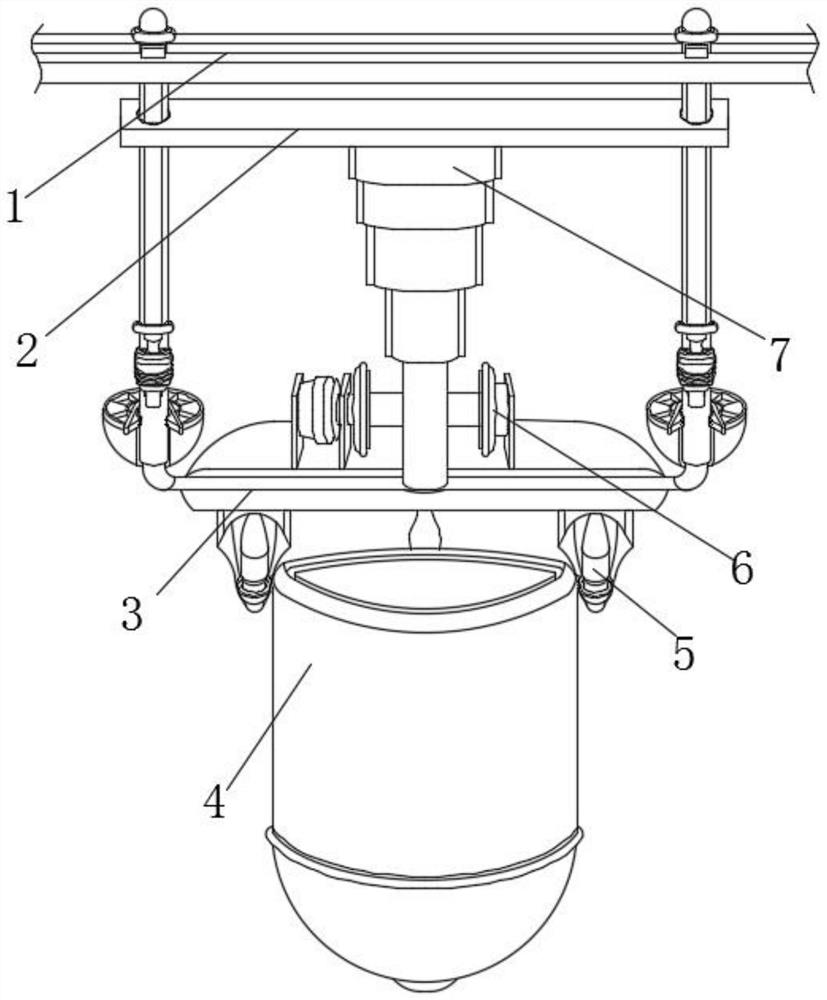

[0038] Working principle: When the device is in use, multiple racks 2 can be installed in the sliding system of the suspended conveyor track 1, so that the racks 2 can be moved in translation on the extended track of the suspended conveyor track 1, so that the fabric is transported in a suspended structure When the fabric is put into the fabric, the U-shaped frame 3 can be guided and cooperated with the inner sle...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap