Method for measuring flue gas temperature based on sound waves

A flue gas temperature and sound wave measurement technology, applied in the application of thermometers, thermometers, measuring devices, etc., can solve the problems of inability to continuously detect, large temperature fluctuation range, etc., achieve good real-time performance, improve signal-to-noise ratio, and ensure reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

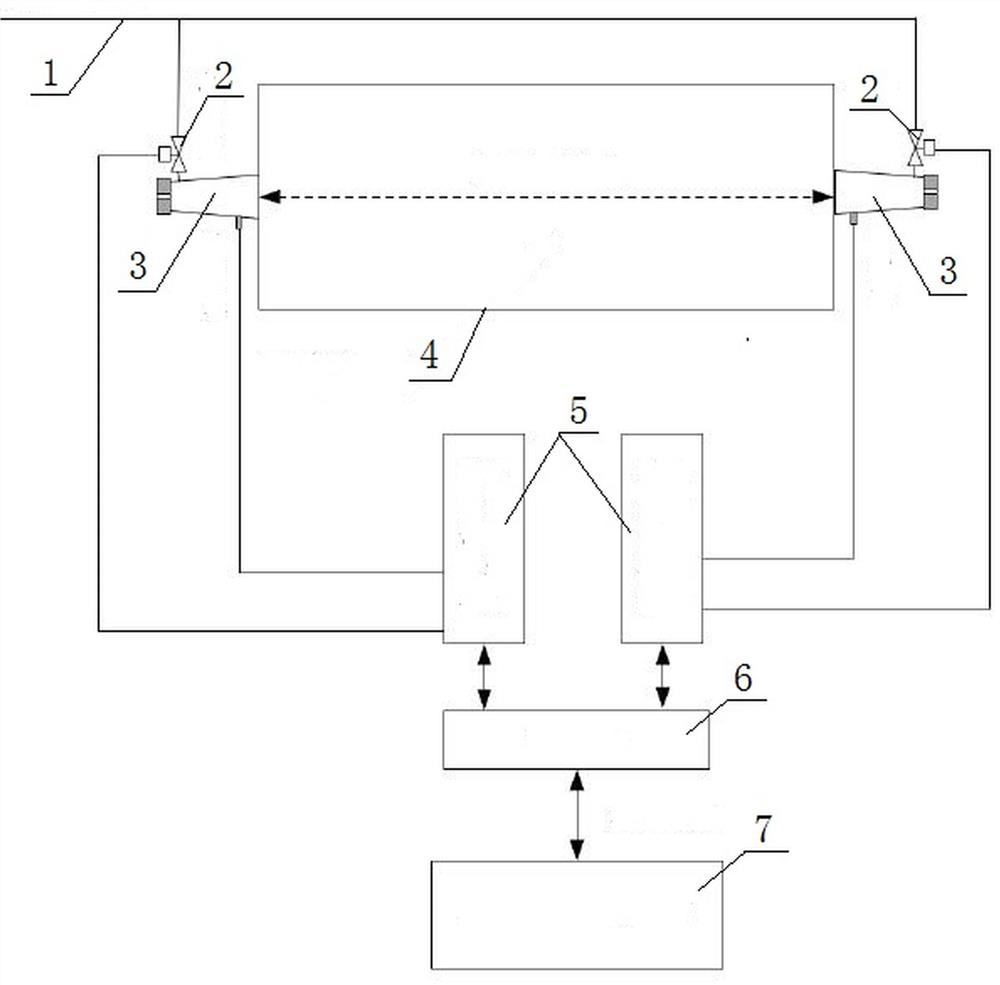

[0030] Such as figure 1 As shown, a method for measuring flue gas temperature based on sound waves includes the following steps:

[0031] S1. Install a pair of sound wave sounding devices symmetrically on the two side walls of the furnace to be tested on the same plane to measure the line temperature;

[0032] S2. The embedded control and detection module 5 controls the solenoid valve 2 to open, and the compressor is used as the power source to input gas through the air pipeline 1 to the sound wave generating device, and the sound wave generating device generates sound waves;

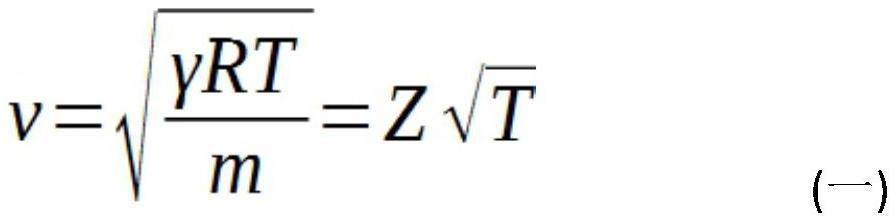

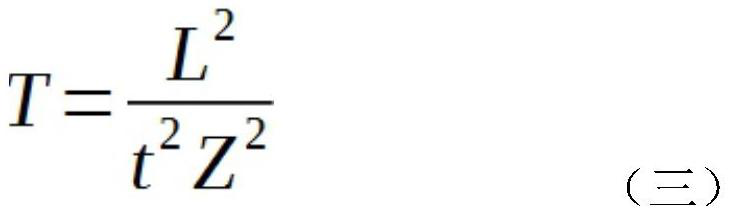

[0033] S3, the sound wave sensor 3 detects the sound wave, and transmits the sound wave signal to the embedded control and detection module 5, the embedded control and detection module 5 records the propagation time t of the sound wave, and measures the propagation distance L between the sound wave sounding device and the sound wave sensor 3, The length of the arrow in the figure is the sound wave tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com