Active-disturbance-rejection control structure and control method for binary rectification process

A technology of active disturbance rejection control and rectification process, which is applied in the field of active disturbance rejection control structure and control of binary distillation process, can solve problems such as waste of process energy, state deviation of rectification tower, and influence on product quality, and achieve control The effect of fewer parameters, low dependence, and easy engineering realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

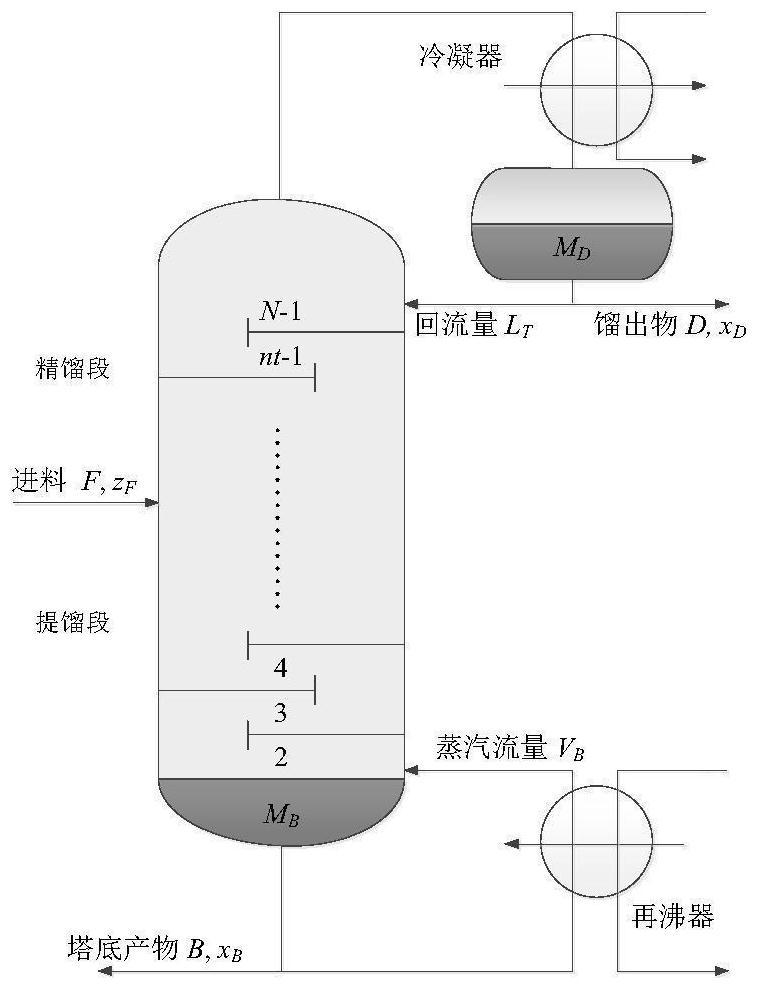

[0046] see Figure 1 to Figure 2 , the technical solution provided by the present invention is a control structure and control method for a rectification tower in a binary rectification process, figure 1 It is a schematic diagram of the binary distillation process. In the figure, the mixture enters the tower from the feed inlet in the middle of the tower. The upper area of the feed inlet is generally called the rectification section, and the lower area of the feed inlet is generally called the stripping section. The light component products come from the top of the rectification section. The condenser is extracted, and the heavy component is extracted from the tower kettle.

[0047] Taking the separation of benzene-toluene mixture by the binary rectification tower as an example, the light component benzene is extracted from the top of the tower, and the heavy component toluene is extracted from the bottom of the tower.

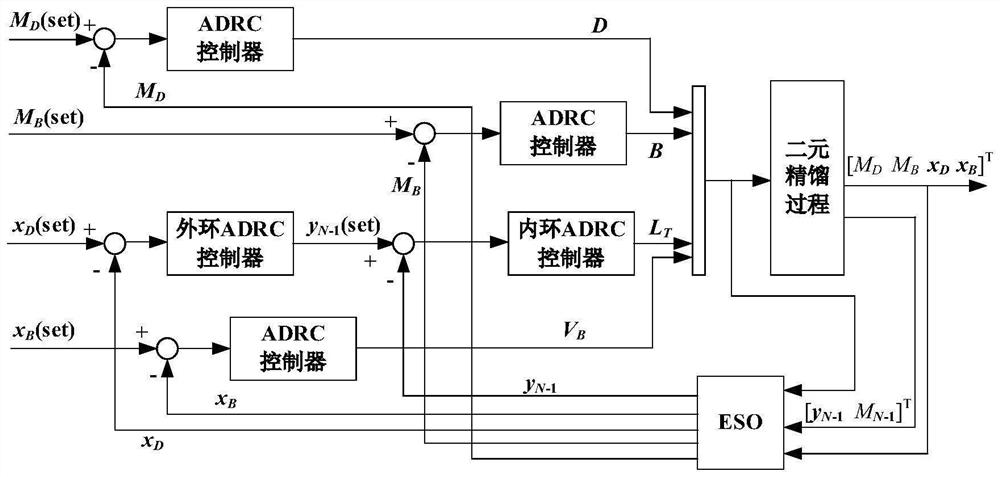

[0048] figure 2 The above control structure is s...

Embodiment 2

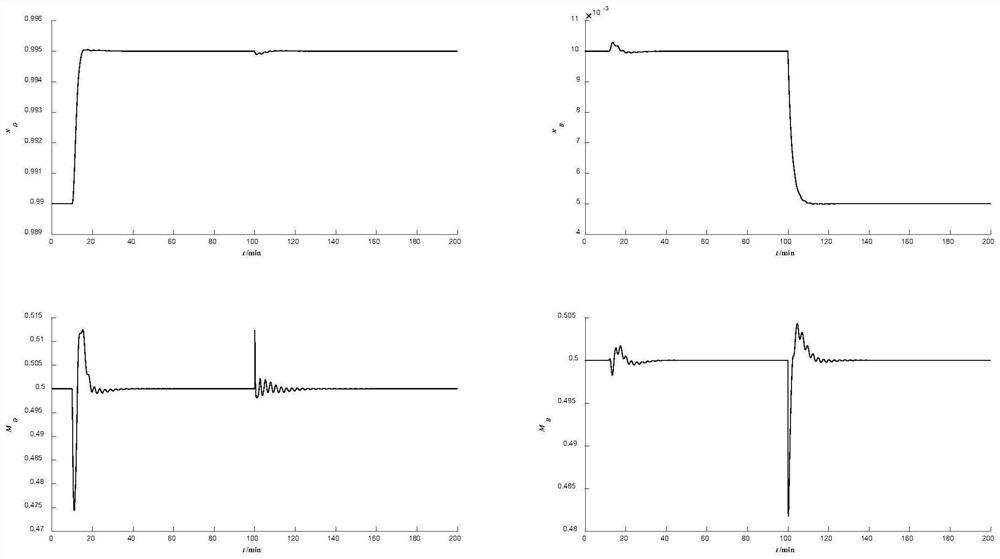

[0069] The binary distillation column with the control structure and control method of Example 1 is used to separate the benzene-toluene mixture. The rectification column is designed with a total of 41 layers, including 39 layers of trays, a reboiler and a condenser, and the feed inlet is located at the 21 layers of trays. After the binary distillation tower runs smoothly, the set value of the light component product concentration at the top of the tower is changed from 0.99 to 0.995 at t=20min, and the set value of the light component product concentration at the bottom of the tower is changed from 0.01 at t=100min is 0.005, and the liquid holdups of the condenser and reboiler remain unchanged. The change of liquid holdup and concentration of light component products at both ends is as follows: image 3 shown. From image 3 It can be seen from the figure that under this control method, the concentration of light component products at the top and bottom of the tower can be ...

Embodiment 3

[0071] The binary distillation column with the control structure and control method of Example 1 is used to separate the benzene-toluene mixture. After the binary distillation tower runs smoothly, the feed flow rate increases by 20% at t=20min, Figure 4 It is the liquid holdup of the condenser and reboiler and the change of the concentration of light component products at both ends. From Figure 4 It can be seen from the figure that under this control method, the concentration of light components at the top and bottom of the tower returns to the set value within 100 minutes, and the absolute values of the maximum fluctuations are less than 0.0001 and 0.00015, respectively. The liquid holdup of the condenser and the reboiler can also return to the set value within 60 minutes after being disturbed, and the absolute value of the maximum fluctuation is less than 0.0017 and 0.0011 respectively. This shows that the control structure and control method have good robust performan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com