An Axially Split Phase Inner Stator Permanent Magnet Bias Magnetic Levitation Switched Reluctance Flywheel Motor

A technology of switched reluctance and permanent magnet bias, applied in the direction of magnetic attraction or thrust holding devices, electrical components, electromechanical devices, etc., can solve the problem of limited critical speed of the flywheel, difficulty in integrating the motor, and long axial length of the motor To reduce the difficulty of suspension control, improve the axial utilization rate and the critical speed of the flywheel, and increase the instantaneous power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

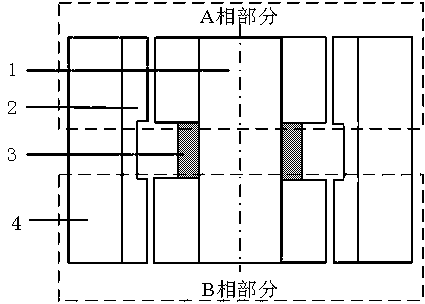

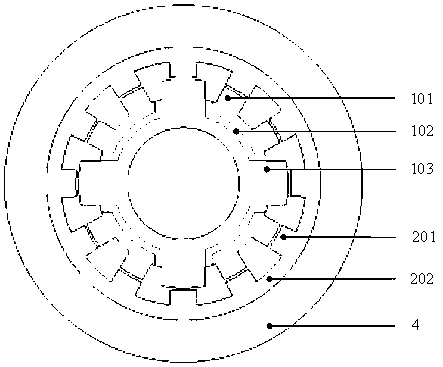

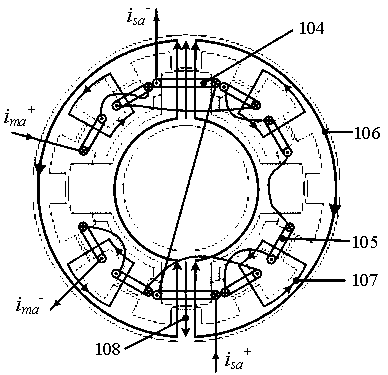

[0021] Such as figure 1 As shown, the present invention is an axial phase split inner stator permanent magnet bias magnetic levitation switched reluctance flywheel motor, comprising an inner stator 1, an outer rotor 2, a permanent magnet ring 3, and a flywheel 4, and the outer rotor 2 is laminated and packaged Inside the flywheel 4, that is to say, the flywheel 4 is fixed on the outside of the outer rotor 2 of the motor. The flywheel and the rotor are combined into one whole, and the inner stator core and the outer rotor core are divided into m segments along the axis according to the number of phases. figure 1 The special case of m=2 is given, which are A-phase part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com