High-productivity vertical furnace

A vertical furnace, high-yield technology, applied in gaseous chemical plating, crystal growth, coating and other directions, can solve the problems of stuck point contamination, stuck point burnt, lower cell yield index, etc. Improve equipment productivity and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

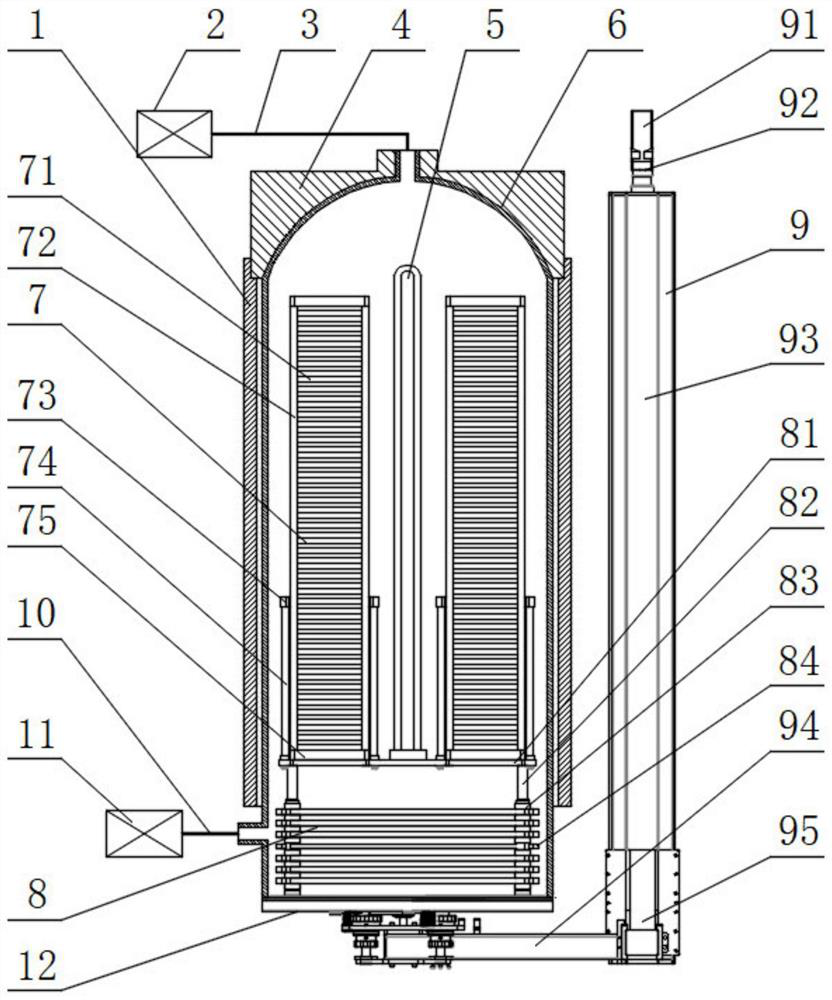

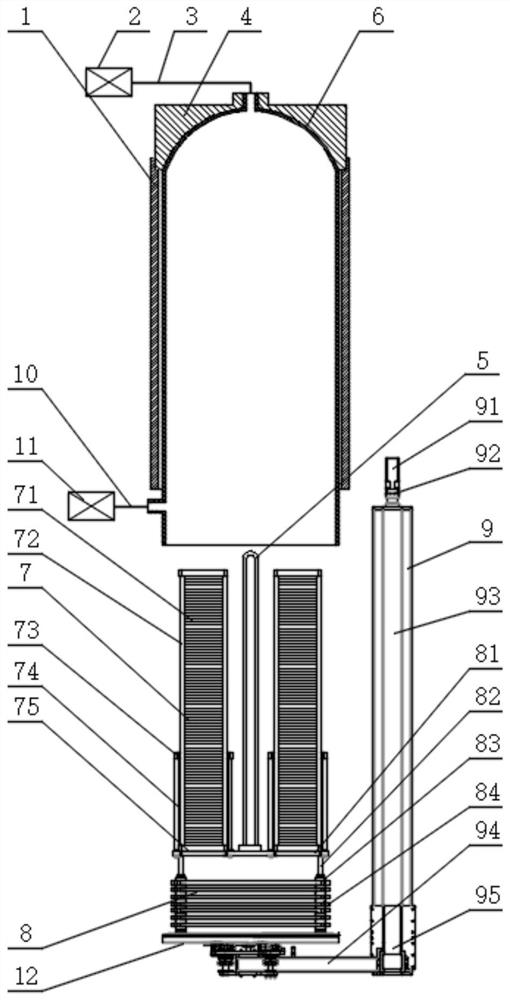

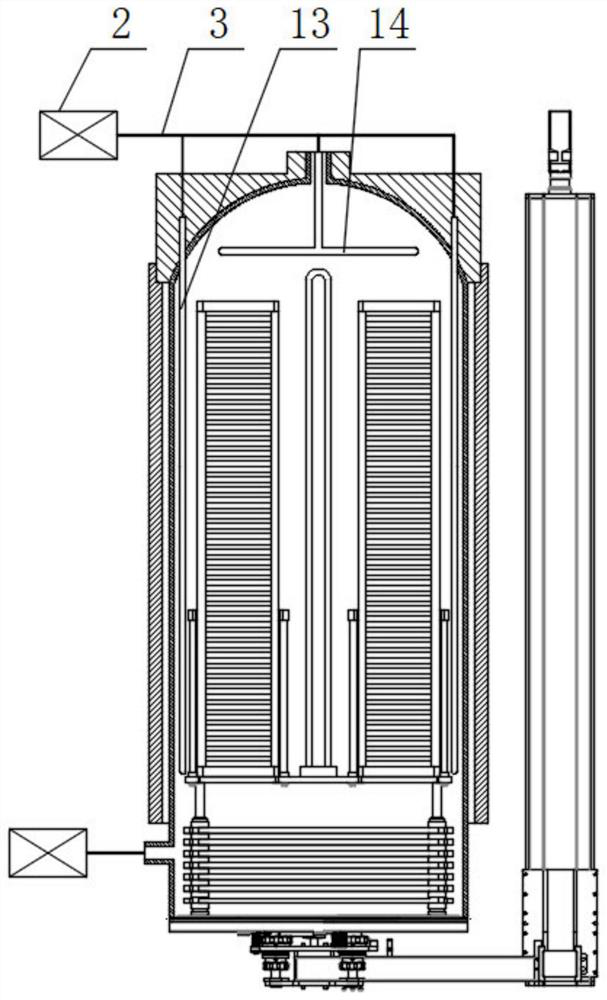

[0030] like Figure 1-Figure 3 As shown, the high-capacity vertical furnace of the present invention includes a furnace body 1, a gas supply system 2, a vacuum system 11, a vertical loading mechanism 9, and an internal heating component 5 installed in the furnace body 1, a process pipe 6, and a carrier boat 7, heat insulation support assembly 8; the furnace body 1 is provided with a furnace door assembly 12, the internal heating component 5 is used as a heating source in the process tube 6, the vertical loading mechanism 9 is connected to the furnace door assembly 12, It is used to realize the opening, closing and sealing of the furnace door in the furnace door assembly 12. The carrier boat 7 is placed on the heat insulation support assembly 8; the gas supply system 2 is used to provide the furnace body 1 with the gas required for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com