High-corrosion-resistance hydrophilic aluminum foil based on renewable resources and processing device of high-corrosion-resistance hydrophilic aluminum foil

A technology of hydrophilic aluminum foil and renewable resources, which is applied to devices for coating liquid on surfaces, special surfaces, coatings, etc. The effect of uniformity in aluminum foil and enhanced anti-mold and anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The present invention provides a highly anti-corrosion hydrophilic aluminum foil based on renewable resources, including aluminum foil and a hydrophilic coating coated on the aluminum foil. The hydrophilic coating is made of the following materials: nano-titanium dioxide, nano-silica, Bisphenol A epoxy resin, modified polyether resin, acrylic resin, methyl silicone resin and polyacrylamide resin, according to the following parts by weight: 15 parts of nano titanium dioxide, 35 parts of nano silicon dioxide, 65 parts of bisphenol A epoxy resin parts, 20 parts of modified polyether resin, 10 parts of acrylic resin, 8 parts of methyl silicone resin and 12 parts of polyacrylamide resin.

Embodiment 2

[0032] The present invention provides a highly anti-corrosion hydrophilic aluminum foil based on renewable resources, including aluminum foil and a hydrophilic coating coated on the aluminum foil. The hydrophilic coating is made of the following materials: nano-titanium dioxide, nano-silica, Bisphenol A epoxy resin, modified polyether resin, acrylic resin, methyl silicone resin and polyacrylamide resin, according to the following parts by weight: 25 parts of nano titanium dioxide, 52 parts of nano silicon dioxide, 85 parts of bisphenol A epoxy resin 32 parts of modified polyether resin, 18 parts of acrylic resin, 14 parts of methyl silicone resin and 21 parts of polyacrylamide resin.

Embodiment 3

[0034] The present invention provides a highly anti-corrosion hydrophilic aluminum foil based on renewable resources, including aluminum foil and a hydrophilic coating coated on the aluminum foil. The hydrophilic coating is made of the following materials: nano-titanium dioxide, nano-silica, Bisphenol A epoxy resin, modified polyether resin, acrylic resin, methyl silicone resin and polyacrylamide resin, according to the following parts by weight: 35 parts of nano titanium dioxide, 70 parts of nano silicon dioxide, 100 parts of bisphenol A epoxy resin 42 parts of modified polyether resin, 24 parts of acrylic resin, 18 parts of methyl silicone resin and 29 parts of polyacrylamide resin.

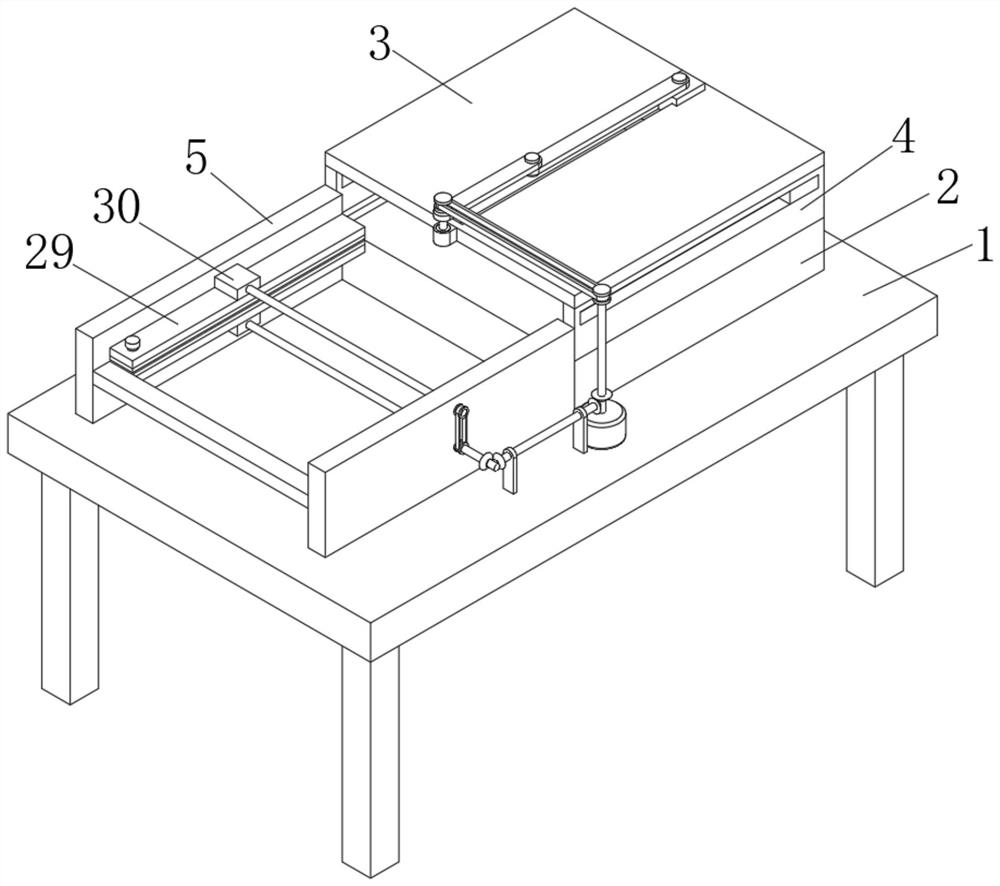

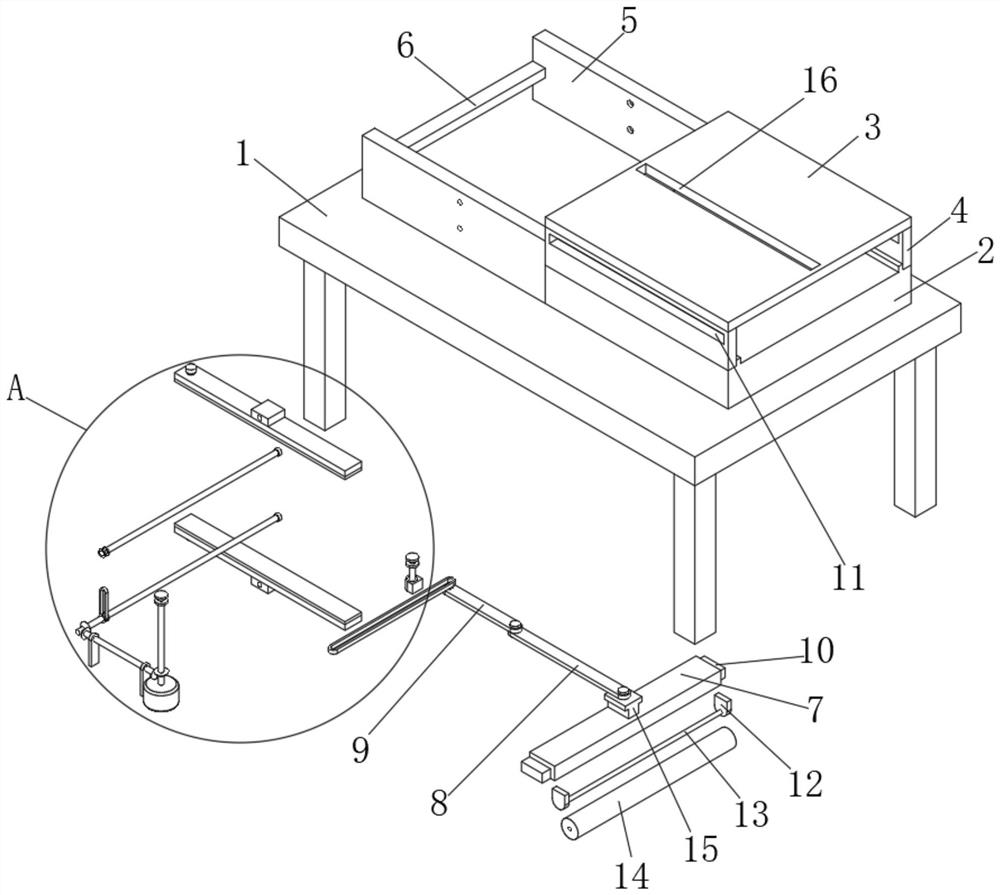

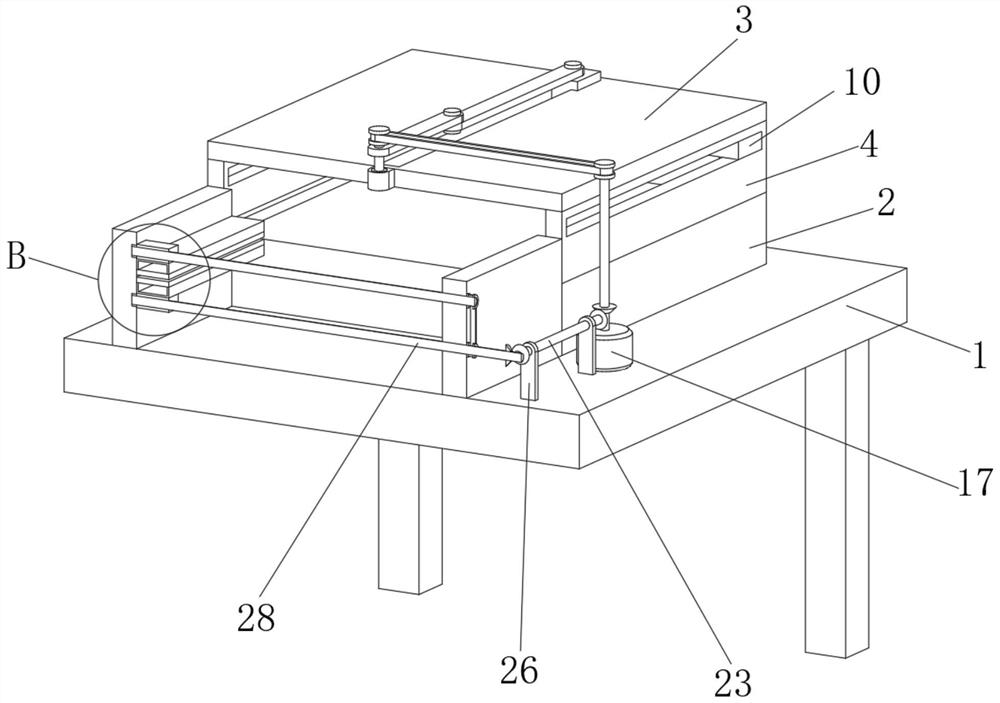

[0035] Refer to attached Figure 1-7 , a processing device for highly anti-corrosion hydrophilic aluminum foil based on renewable resources provided by the present invention, comprising a processing table 1, one end of the top of the processing table 1 is fixedly connected with a support seat 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com