Miniaturized low-concentration multistage seawater desalination system

A concentrator and stage evaporation technology, applied in seawater treatment, general water supply conservation, water/sewage treatment, etc., can solve the problems of declining economic efficiency, occurrence on the interface, low heat flux density, etc., to improve the water production rate, The effect of increasing water production and improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The content of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the embodiments of the present invention are not limited thereto.

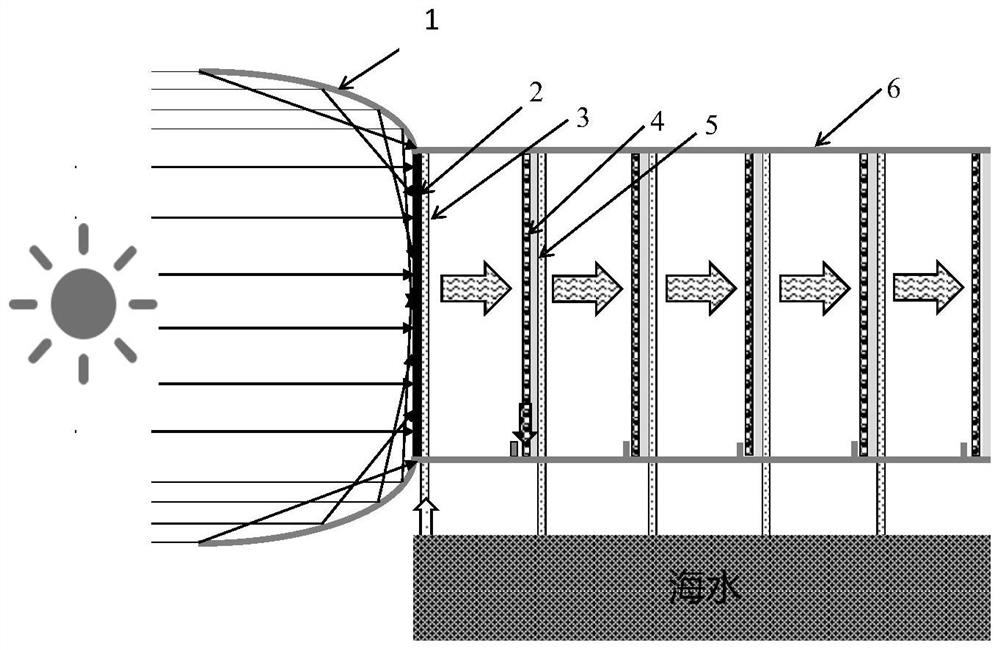

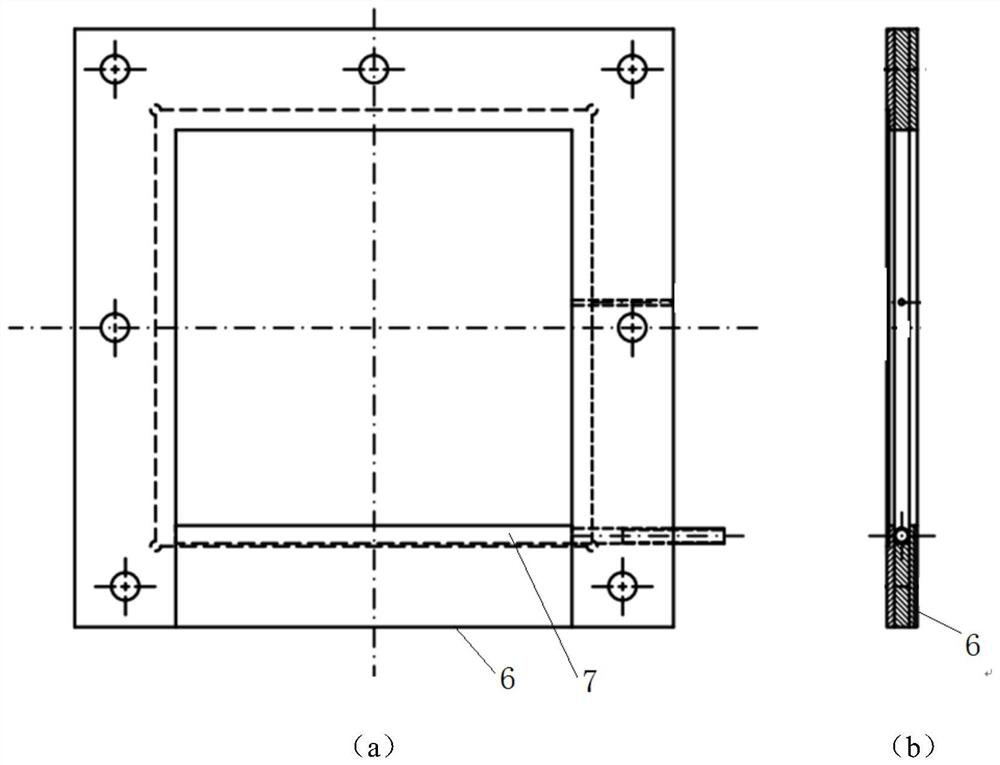

[0026] Such as figure 1 As shown, a miniaturized low-power concentrating multi-stage seawater desalination system provided by the present invention mainly includes a parabolic trough concentrator 1 that eliminates multiple reflections with a double concentration ratio, a light-to-heat conversion layer 2, and a capillary suction Liquid core 3, condenser plate 5 and frame 6 machined from PMMA. The concentrator 1 is arranged along a direction perpendicular to the sun's rays. The light outlet of the concentrator 1 is provided with a light-to-heat conversion layer 2, the surface of the other side of the light-to-heat conversion layer 2 is provided with a capillary wick 3, and the other side of the capillary wick 3 is provided with several stages of evapor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com