Heating, heat-insulating and energy-saving wallboard and manufacturing method thereof

A manufacturing method and a technology for wall panels, which are applied in the field of building panels, can solve the problems of poor thermal insulation effect, melting and cracking of wall materials, and difficulty in storing heat by microcapsules, and achieve a good effect of heat storage and heat release.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

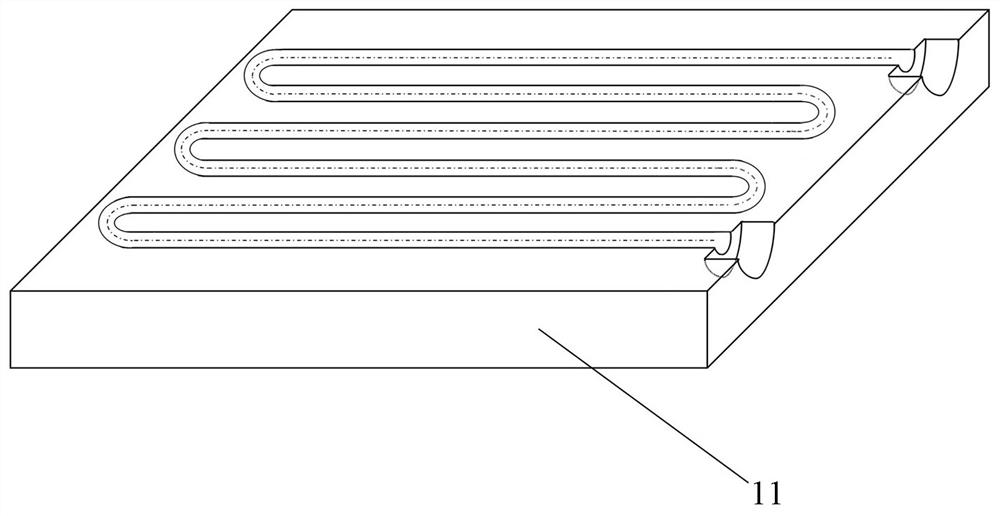

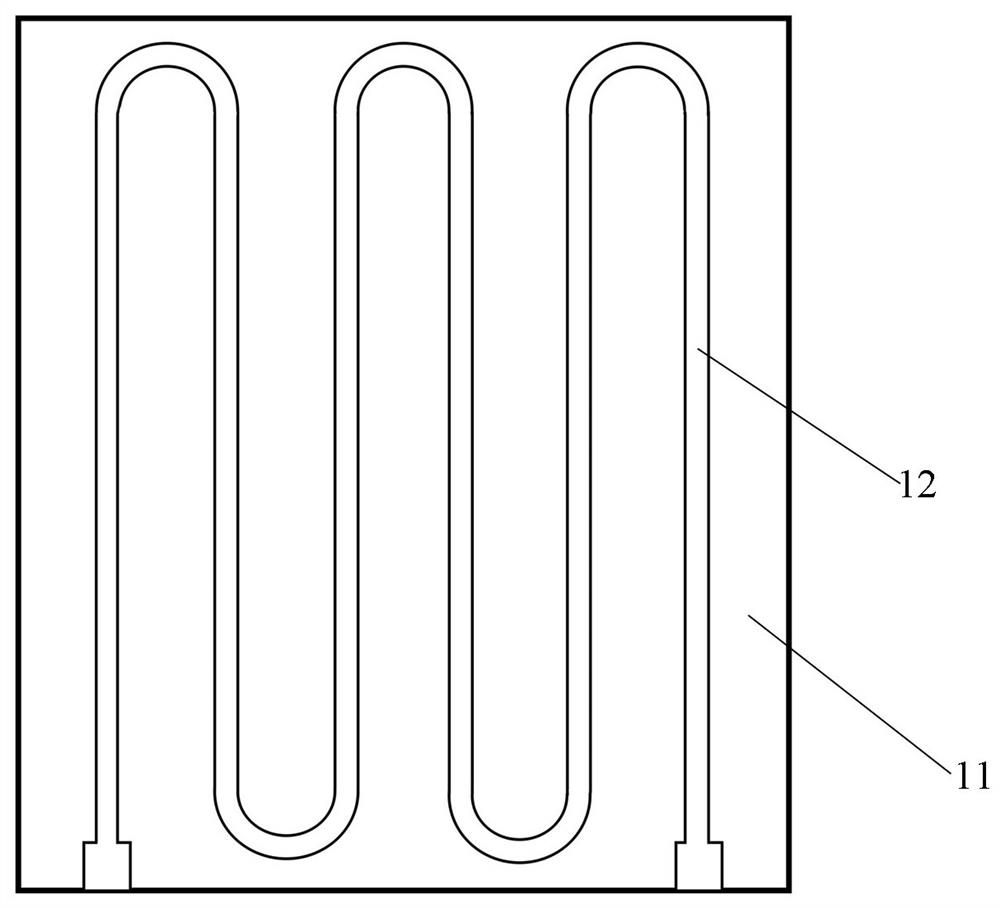

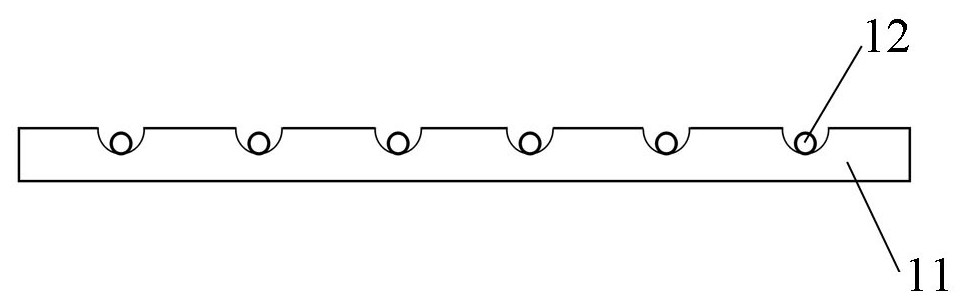

[0031] A heating and heat preservation energy-saving wallboard, such as figure 1 As shown, it includes a heating layer 1 and an outer layer 2 disposed on at least one side of the heating layer 1 . In this embodiment, the outer layers 2 are respectively disposed on two opposite sides of the heating layer 1 .

[0032] Wherein, the heating layer 1 includes a base plate 11 and a heating element 12 arranged on the base plate 11. The base layer 11 is formed by vertically stacking several wood boards. Phase-change microcapsules loaded on the surface and inside of the wood board. At the same time, the adjacent wood boards are connected by an adhesive layer, and the adhesive layer includes phase change microcapsules. Heating element 11 adopts carbon fiber heating wire, such as figure 2 and image 3 As shown, a serpentine wire groove is opened on the substrate 11, such as Figure 4 As shown, the width and depth of the notch are suitable for the diameter of the carbon fiber heating ...

Embodiment 2

[0048] This embodiment is basically the same as Embodiment 1, and its difference only lies in:

[0049] The heat-preserving and energy-saving wallboard is prepared through the following steps:

[0050] Prepare phase-change microcapsules with phase-change paraffin as core material, polymer compound as wall material, particle size of 40-50 μm, and melamine adhesive. Disperse a part of the phase-change microcapsules in water to make a phase-change microcapsule suspension; mix a part of the phase-change microcapsules with the melamine adhesive at a mass ratio of 0.15:1, and then add 20% flour of the mixture mass , Stir again until there are no particles to make an adhesive.

[0051] S1. Rotary cutting selection of wood boards: select eucalyptus logs, use a shaft-free rotary cutter for rotary cutting, and select a number of high-quality wood boards with no surface defects.

[0052] Board pretreatment: Soak the peeled wood board in hot water at 65°C for 2 hours, take it out after ...

Embodiment 3

[0063] This embodiment is basically the same as Embodiment 1, and its difference only lies in:

[0064] The heat-preserving and energy-saving wallboard is prepared through the following steps:

[0065] Prepare phase-change microcapsules with phase-change paraffin as core material, polymer compound as wall material, particle size of 25-35 μm, and melamine adhesive. Disperse a part of the phase-change microcapsules in water to make a phase-change microcapsule suspension; mix a part of the phase-change microcapsules with the melamine adhesive at a mass ratio of 0.3:1, and then add 30% flour of the mass of the mixture , Stir again until there are no particles to make an adhesive.

[0066] S1. Rotary cutting selection of wood boards: select poplar logs, use a shaft-free rotary cutter for rotary cutting, and select a number of high-quality wood boards with no defects on the surface.

[0067] Wood pretreatment: Soak the rotary-cut wood in hot water at 75°C for 4 hours, take it out ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com