A heat storage material for an air preheater in a power plant and a preparation method thereof

A heat storage material and air preheater technology, applied in the direction of heat exchange materials, chemical instruments and methods, combustion methods, etc., can solve the problems of acid corrosion resistance, air pollution, inner hole blockage, etc. Abrasion, well-formulated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

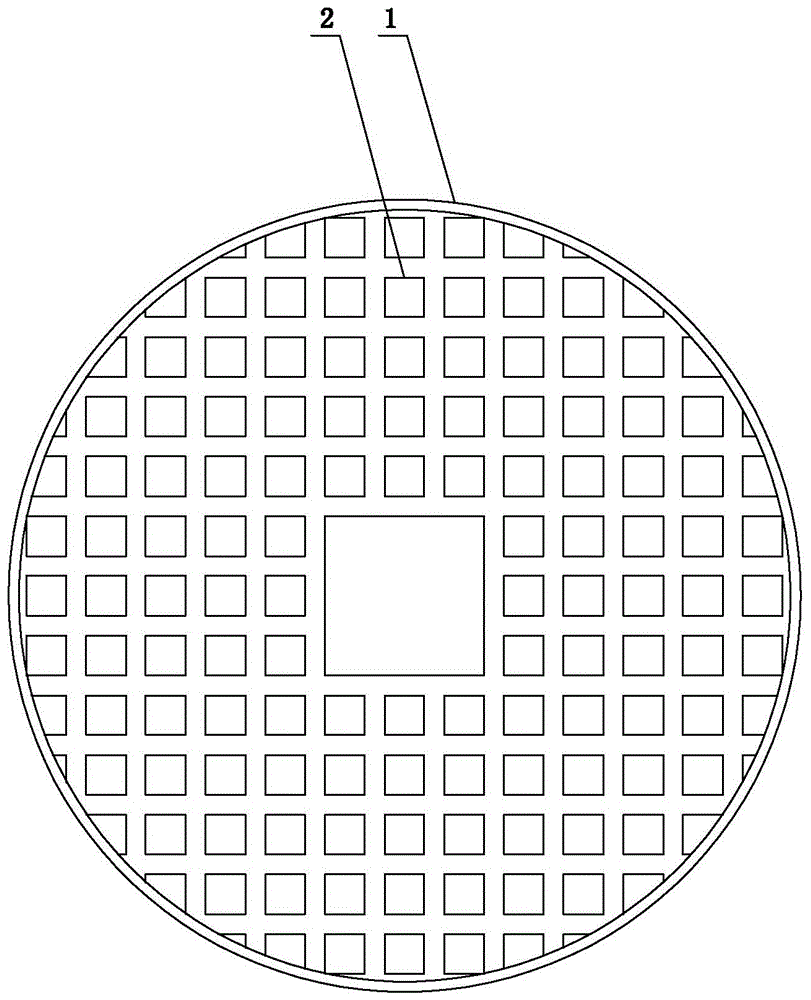

Image

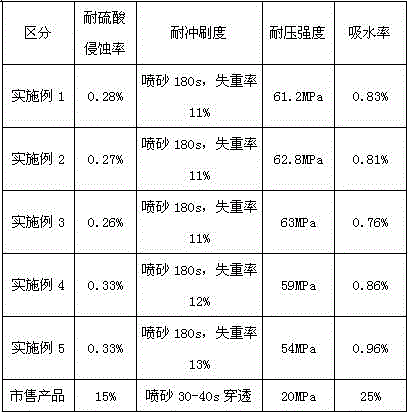

Examples

Embodiment 1

[0018] Embodiment 1: A kind of production method of heat storage material of new type power plant air preheater, comprises the following steps:

[0019] 1) Weigh 25 parts of white corundum (1KG each, the same below), 30 parts of α-alumina, 20 parts of kaolin, 10 parts of quartz powder, 6.5 parts of talc, 5 parts of potassium feldspar, 3.5 parts of barium carbonate powder, pour into the powder mixing homogenizer (produced by Zhengzhou Yineng Technology Co., Ltd., the same below);

[0020] 2) Weigh 2.5 parts of water;

[0021] 3) take by weighing 0.4 part of tung oil;

[0022] 4) Turn on the powder mixing homogenizer, knead the above-mentioned materials in the powder mixing homogenizer, and then send the materials to the vacuum mud refining machine for initial refining, stale, refining, extrusion molding, Send it to the drying machine for shaping, drying, and firing to obtain the finished product.

Embodiment 2

[0023] Embodiment 2: A kind of production method of heat storage material of new type power plant air preheater, comprises the following steps:

[0024] 1) Weigh 30 parts of white corundum, 25 parts of α-alumina, 15 parts of kaolin, 10 parts of quartz powder, 3 parts of talc, 10 parts of potassium feldspar, and 7 parts of barium carbonate powder, and pour them into the powder mixing homogenizer middle;

[0025] 2) Weigh 3.5 parts of water;

[0026] 3) take by weighing 0.8 part of tung oil;

[0027] 4) Turn on the powder mixing homogenizer, knead the above-mentioned materials in the powder mixing homogenizer, and then send the materials to the vacuum mud refining machine for initial refining, stale, refining, extrusion molding, Send it to a microwave dryer for shaping, drying, and firing to obtain a finished product.

Embodiment 3

[0028] Embodiment 3: A kind of production method of heat storage material of new type air preheater of power plant, comprises the following steps:

[0029] 1) Weigh 35 parts of white corundum, 20 parts of α-alumina, 10 parts of kaolin, 10 parts of quartz powder, 5 parts of talc, 10 parts of potassium feldspar, and 10 parts of barium carbonate powder and pour them into the powder mixing homogenizer ;

[0030] 2) Weigh 4 parts of water;

[0031] 3) Weigh 1.2 parts of tung oil;

[0032] 4) Turn on the powder mixing homogenizer, knead the above-mentioned materials in the powder mixing homogenizer, and then send the materials to the vacuum mud refining machine for initial refining, stale, refining, extrusion molding, Send it to a microwave dryer for shaping, drying, and firing to obtain a finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com