Zirconium-oxide large-size ceramic regenerator and preparation technology thereof

A preparation process and heat storage body technology, applied in the field of industrial energy saving and emission reduction equipment, can solve the problems of honeycomb ceramics, such as low wear resistance, low corrosion resistance, low mechanical strength, low heat exchange efficiency, etc., to achieve heat resistance Excellent impact and compression resistance, good corrosion resistance, and high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

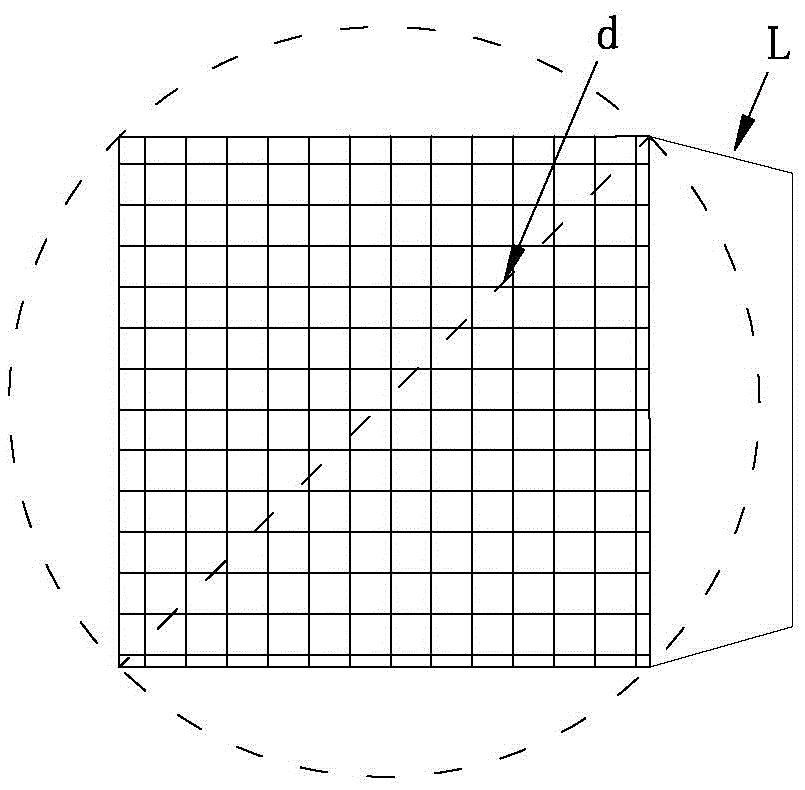

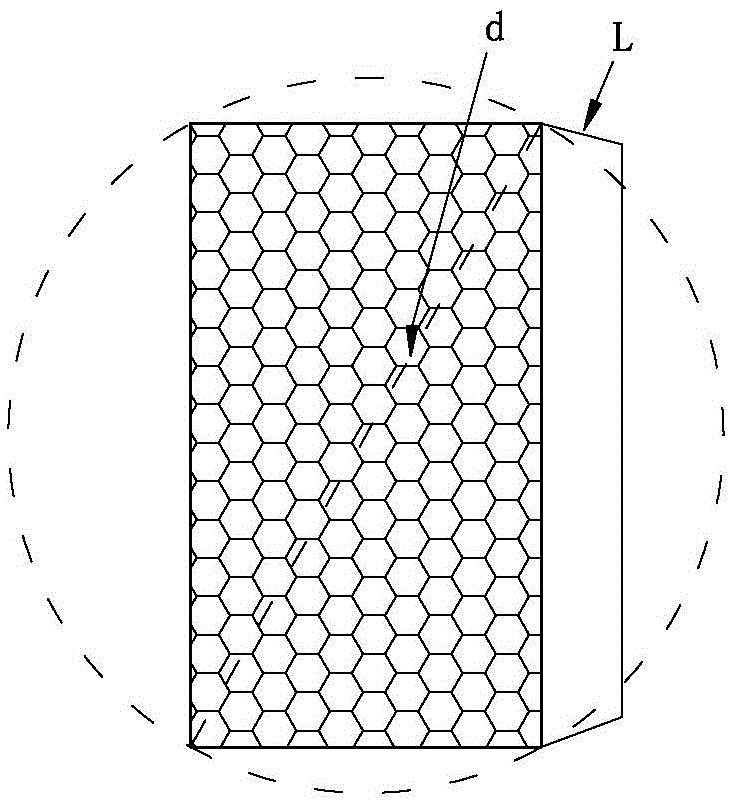

[0034]The large-scale ceramic regenerator produced has a square cross-section; its preparation process is: (1) dry mixing, firstly add the inorganic powder into the ball mill, dry mix for 4 hours, pass through a 100-mesh sieve, and the inorganic powder is made of the following weight Proportioned components: 80 parts of zirconia, 2 parts of alumina micropowder, 2 parts of silicon dioxide, 1 part of boron nitride, 1 part of neodymium oxide, 1 part of barium oxide, 2 parts of zinc oxide, 4 parts of carbon fiber; ( 2) Add additives, the additive components are 4 parts by weight of hydroxyethyl cellulose, 1 part by weight of polyvinyl alcohol, 1 part by weight of polyethylene oxide, and 2 parts by weight of (polyethylene glycol 400); (3) kneading, in a kneader Add water and lubricating oil while stirring. When kneading, after adding 400kg of material, add water in 5 times while stirring. After adding water, continue stirring for 5 minutes and add tung oil at one time. Stop stirring...

Embodiment 2

[0037] The large-scale ceramic regenerator produced has a square cross-section; its preparation process is: (1) dry mixing, firstly add the inorganic powder into the ball mill, dry mix for 6 hours, pass through the 80-mesh sieve, and the inorganic powder is made of the following weight Proportioned components: 85 parts of zirconia, 4 parts of alumina micropowder, 3 parts of silicon dioxide, 2 parts of boron nitride, 2 parts of neodymium oxide, 1 part of barium oxide, 3 parts of zinc oxide, and 8 parts of carbon fiber; ( 2) Adding additives, the additive components are 1 weight part of methyl cellulose, 4 weight parts of cyanoethyl cellulose, 2 weight parts of polyvinyl alcohol, 1 weight part of polyethylene oxide, and 2 weight parts of polypropylene glycol; (3) kneading, Add water and lubricating oil while stirring in the kneader. When kneading, after adding 400kg of material, add water in 3 times while stirring. After the water is added, continue stirring for 2 minutes and add...

Embodiment 3

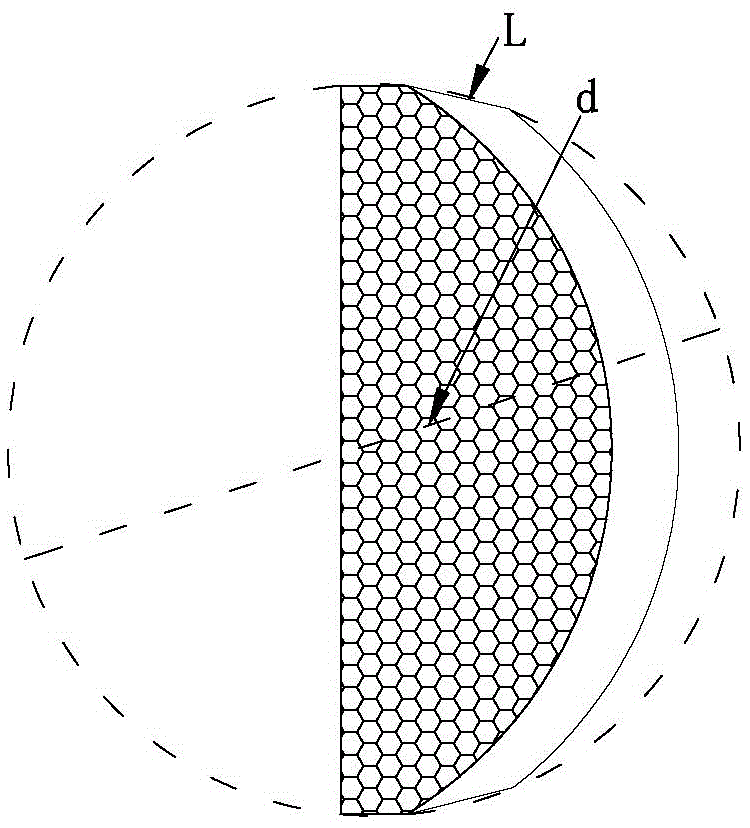

[0040] The large-scale ceramic regenerator produced has a rectangular cross-section; its preparation process is: (1) dry mixing, first add inorganic powder into the ball mill, add the required powder into the ball mill, dry mix for 3 hours, and pass through 80 mesh The screen, the inorganic powder is composed of the following components by weight: 90 parts of zirconia, 6 parts of alumina micropowder, 4 parts of silicon dioxide, 2.0 parts of boron nitride, 2 parts of neodymium oxide, 2 parts of barium oxide, 3 parts of zinc, 5 parts of carbon fiber; (2) adding additives, the additive components are 2 parts by weight of methyl cellulose, 1 part by weight of hydroxyethyl cellulose, 1 part by weight of cyanoethyl cellulose, 2 parts by weight of polyvinyl alcohol, 1 part by weight of polyethylene oxide, 3 parts by weight of hexylene glycol; (3) Kneading, add water and lubricating oil while stirring in the kneader, when kneading, add 400kg of material, stir for 15 minutes and then ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com