A combined multi-channel diffuser of a gas turbine and its diffuser intake structure

A gas turbine and air intake structure technology, which is applied in the combustion chamber, combustion method, combustion equipment, etc., can solve the problems of air pressure deceleration performance and the overall length cannot be taken into account, and achieve the effect of improving the diffusion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

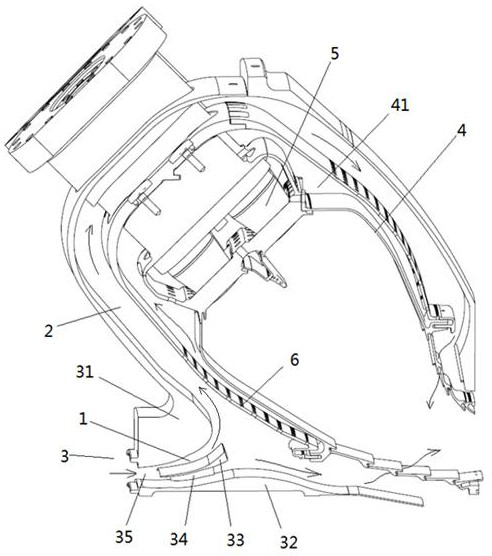

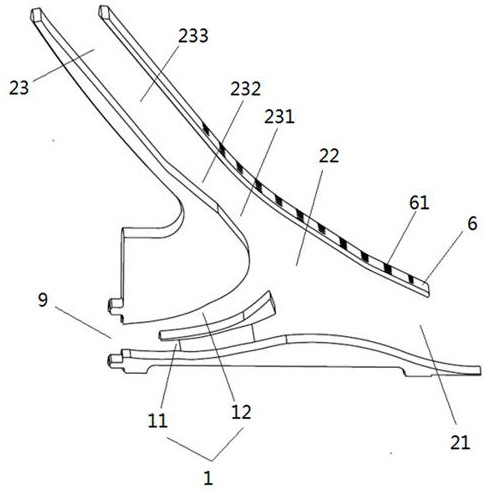

[0033] like Figure 1 to Figure 2 As shown, this embodiment designs a diffuser air intake structure of a gas turbine, which is used to diffuse and decelerate the air entering the casing 3 of the gas turbine combustion chamber.

[0034]With the development of the structure of the gas turbine engine, its rotational speed is getting faster and faster, which makes the airflow velocity at the outlet of the compressor inside the gas turbine very large, and when such a high-speed airflow enters the combustion chamber of the gas turbine, it will Affects ignition combustion in the combustion chamber. Therefore, a corresponding diffuser structure is designed to diffuse and decelerate the air entering the combustion chamber to ensure that the air flow velocity is generally reduced to five times the air velocity at the compressor outlet before reaching the combustion chamber for combustion. It can form a stable outlet flow field, so as to ensure the stable combustion of the combustion ch...

Embodiment 2

[0046] like Figure 1 to Figure 2 As shown, this embodiment designs a combined multi-channel diffuser for a gas turbine, and the combined multi-channel diffuser is installed on the combustion chamber casing 3 of the gas turbine, as shown in figure 1 shown.

[0047] The combustion chamber casing 3 is provided with structures such as a flame tube 4 and a fairing 6. The flame tube 4 is an annular groove-shaped structure as a whole, and the bottom of the flame tube 4 is used to install the premixer 5. The notch of the flame tube 4 is the outlet of the flame tube 4; the fairing 6 is covered outside the flame tube 4, and an outer wall cooling channel 41 for cooling the wall of the flame tube 4 is formed between the two; The fairing 6 is provided with ventilation holes 61 .

[0048] The combined multi-channel diffuser in this embodiment includes a diffuser outer ring 31 , a diffuser inner ring 32 , a flow divider 33 and the diffuser air intake structure in Embodiment 1. The diffuse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com