Solar energy storage and heat supply tobacco leaf curing system and control method

A technology of solar heating and solar energy, applied in the field of baking system and control, can solve the problems of instability, low efficiency of solar energy utilization, large energy conversion loss, etc., and achieve the effect of convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

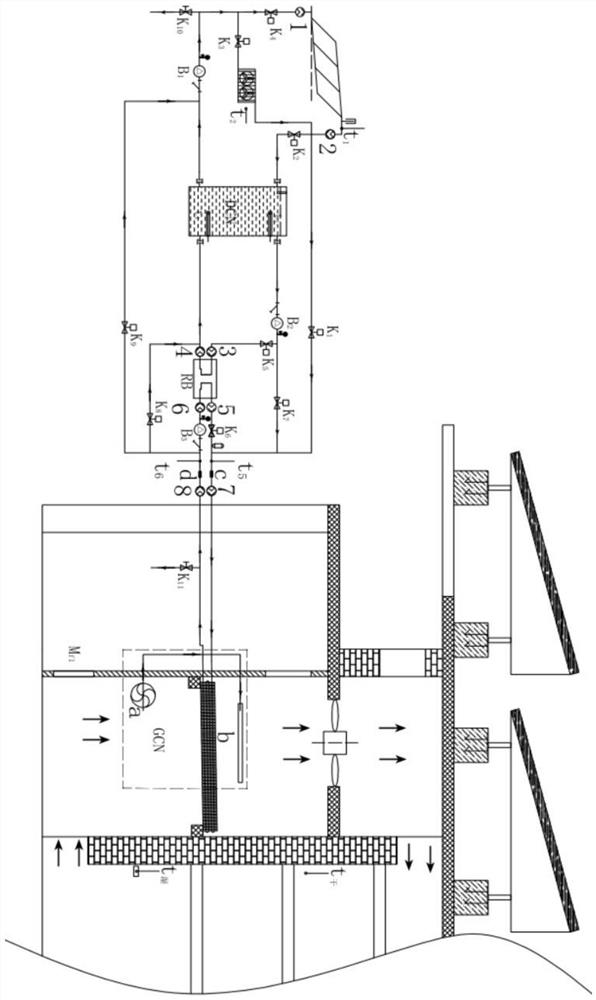

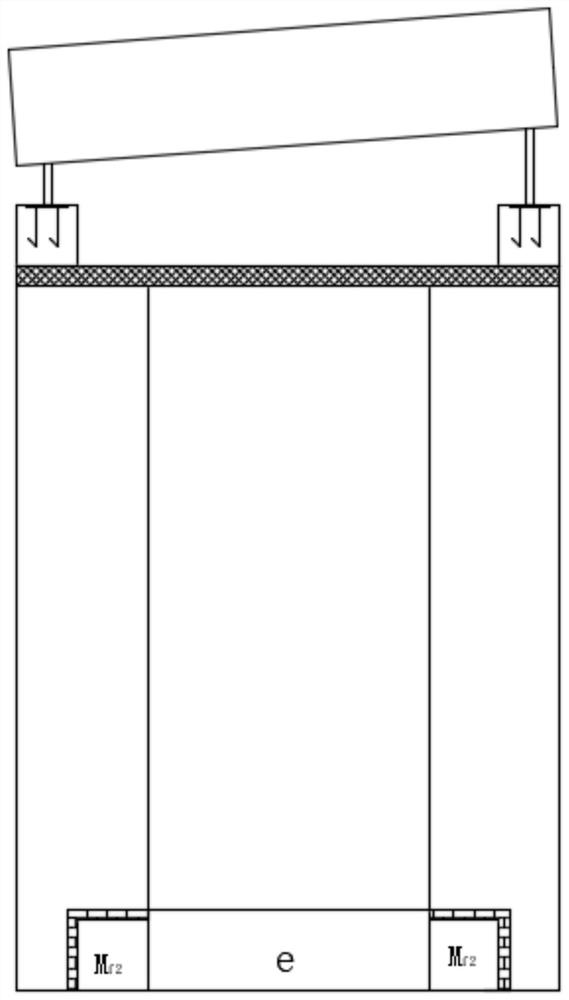

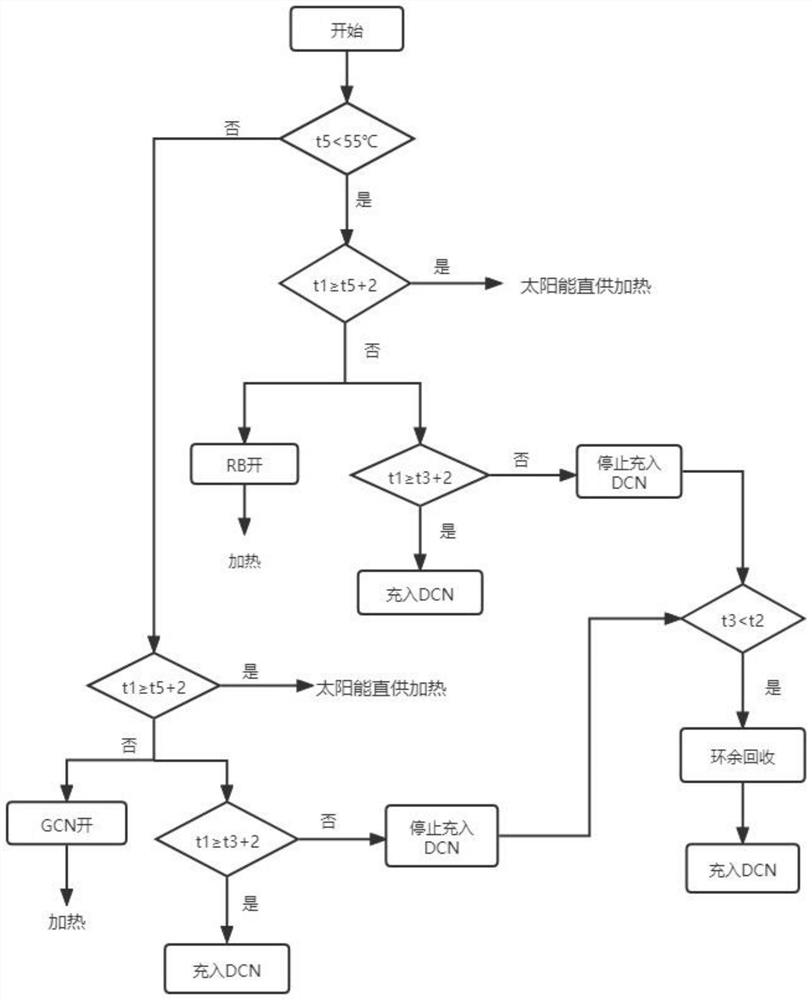

[0034] Such as Figure 1-2 As shown, the solar energy storage heating tobacco leaf curing system includes a control mechanism and a barn. The barn is provided with a hot air return air outlet e and a moisture discharge port. The moisture discharge port is provided with a moisture discharge port damper M f2 , the interior of the drying room is provided with a dry bulb temperature sensor and a wet bulb temperature sensor, and the baking system also includes the following modules:

[0035]A high-temperature energy storage heating module, the high-temperature energy storage heating module includes an air supply mechanism a, an energy storage mechanism (not shown in the figure), a valley electric heating mechanism (not shown in the figure), and an air inlet and outlet. The energy mechanism is electrically connected to the external power supply and can charge and release heat. The air supply mechanism and the valley electric heating mechanism are electrically connected to the extern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com