Method for preparing high-strength and high-plasticity 316L stainless steel through large-strain warm rolling

A stainless steel, high-strength technology, applied in the direction of metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of unfavorable promotion and production, and achieve the effects of continuous production, easy processing and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

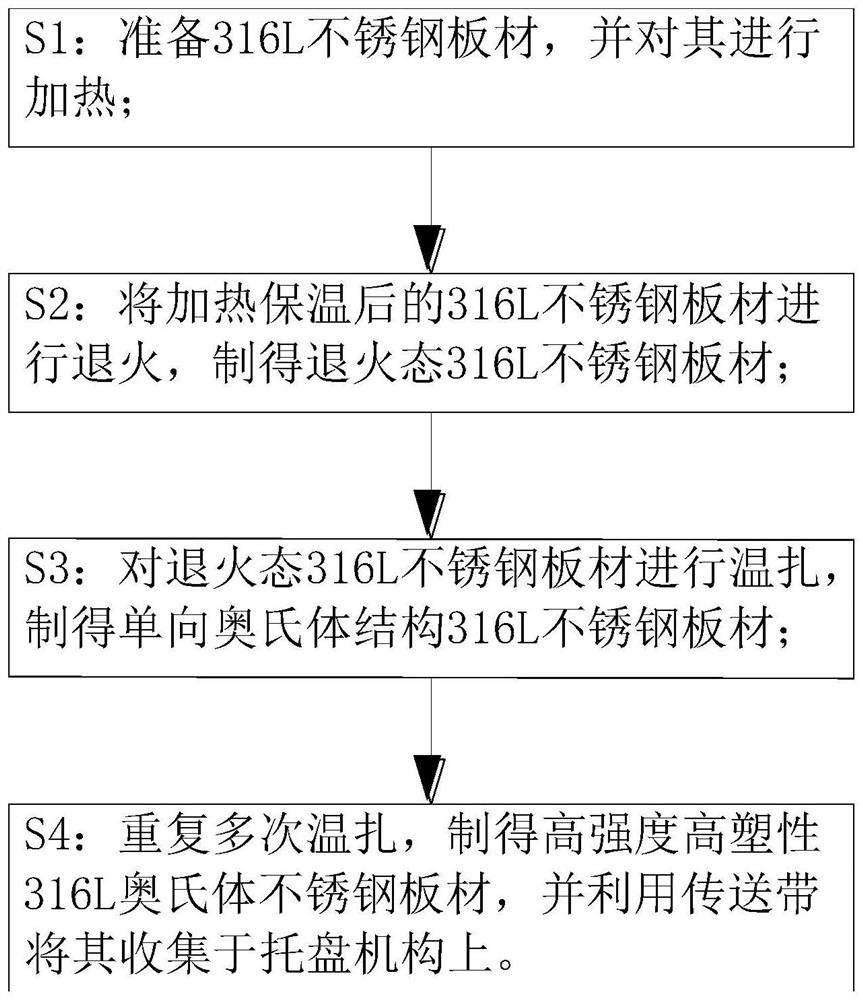

[0035] Such as Figure 1 to Figure 9 As shown, a kind of large-strain warm rolling of the present invention prepares the method for high-strength high-plasticity 316L stainless steel, and this method comprises the following steps:

[0036] S1: Prepare 316L stainless steel plate and heat it;

[0037] S2: annealing the 316L stainless steel plate after heating and heat preservation to obtain an annealed 316L stainless steel plate;

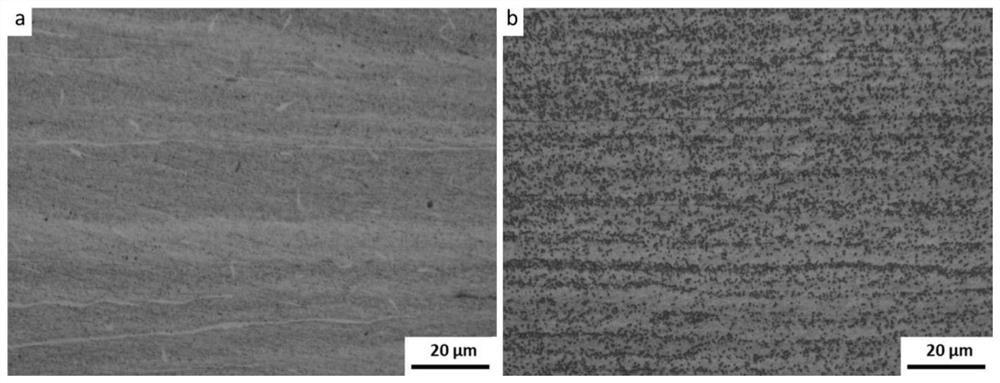

[0038] S3: Warm rolling the annealed 316L stainless steel sheet to obtain a unidirectional austenitic structure 316L stainless steel sheet;

[0039] S4: Warm rolling is repeated several times to obtain a high-strength and high-ductility 316L austenitic stainless steel plate, which is collected on a tray mechanism by a conveyor belt.

[0040] As an embodiment of the present invention, in S3, before warm rolling, the 316L stainless steel plate needs to be placed in a heating furnace at 300°C for 10 minutes; during the warm rolling process, the anneale...

Embodiment approach

[0042] As an embodiment of the present invention, in the S1, the mass percentages of the components of the 316 stainless steel plate are: C: 0.03, Si: 1.0, Mn: 2.0, p: 0.045, S: 0.03, Ni: 10.0, Cr: 16.0, Mo: 2.0, and the rest are Fe and unavoidable impurities.

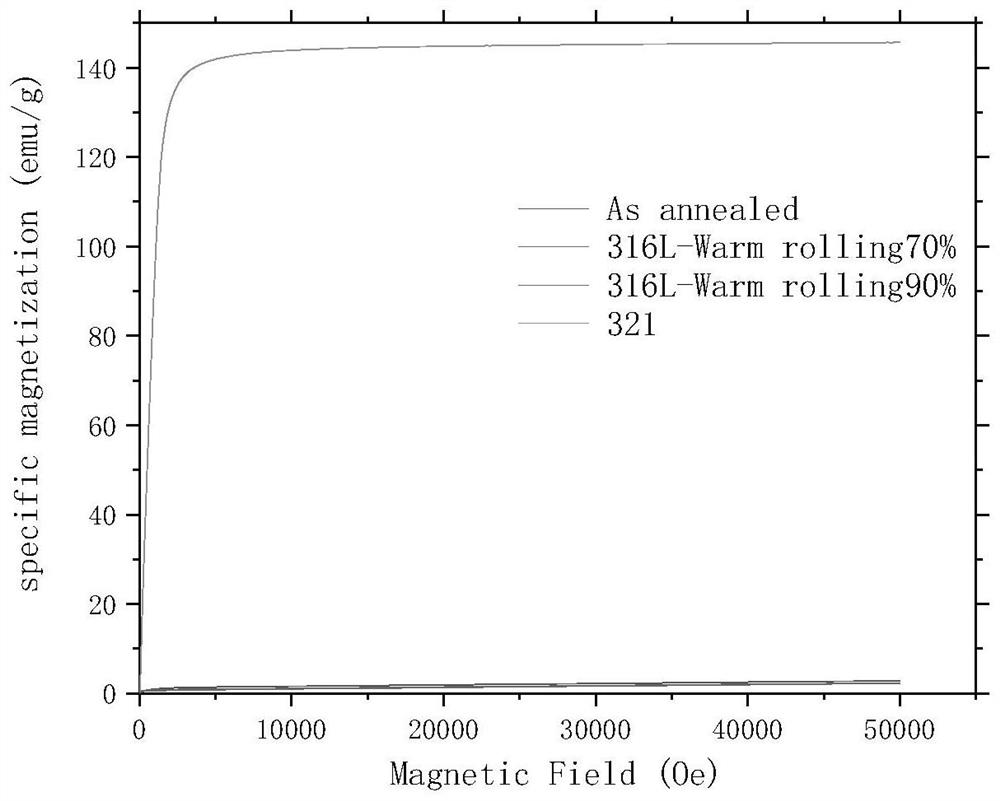

[0043] In this embodiment, the 316L stainless steel plate obtained by the above method has a yield strength of 887 MPa, a tensile strength of 984 MPa, and a uniform elongation of 5.7%.

[0044] As an embodiment of the present invention, the tray mechanism is composed of a tray body 3, a movable plate 32, a buffer assembly and a connecting bracket 33; the movable plate 32 is hinged at one end of the top surface of the tray body 3; the buffer assembly is provided with Between the movable plate 32 and the tray body 3; the connecting bracket 33 is movably connected to one end of the tray body 3;

[0045] Described buffer assembly is made up of hinged rod 36, straight rod 362, No. 1 spring 363 and elastic plate 35; One end o...

Embodiment 2

[0056] Such as Figure 1 to Figure 9 As shown, a kind of large-strain warm rolling of the present invention prepares the method for high-strength high-plasticity 316L stainless steel, and this method comprises the following steps:

[0057] S1: Prepare 316L stainless steel plate and heat it;

[0058] S2: annealing the 316L stainless steel plate after heating and heat preservation to obtain an annealed 316L stainless steel plate;

[0059] S3: Warm rolling the annealed 316L stainless steel sheet to obtain a unidirectional austenitic structure 316L stainless steel sheet;

[0060] S4: Warm rolling is repeated several times to obtain a high-strength and high-ductility 316L austenitic stainless steel plate, which is collected on a tray mechanism by a conveyor belt.

[0061] As an embodiment of the present invention, in S3, before warm rolling, the 316L stainless steel plate needs to be placed in a heating furnace at 300°C for 10 minutes; during the warm rolling process, the anneale...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com