Wire drawing system for steel wire drawing

A wire drawing and steel wire technology, applied in the direction of wire drawing dies, etc., can solve the problems of steel wire surface quality and mechanical properties degradation, 4-point angular contact bearings are easily damaged due to high force, and the wear of the single-side pass of the wire drawing die is aggravated. The effect of water leakage failure, solving the problem of broken screws, improving surface quality and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

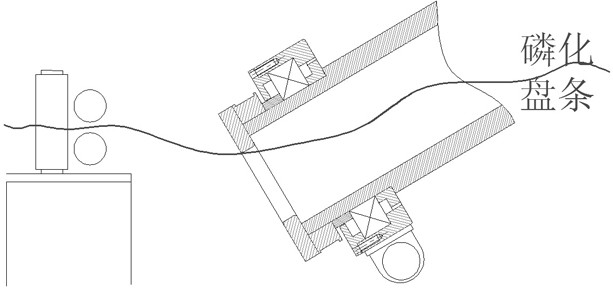

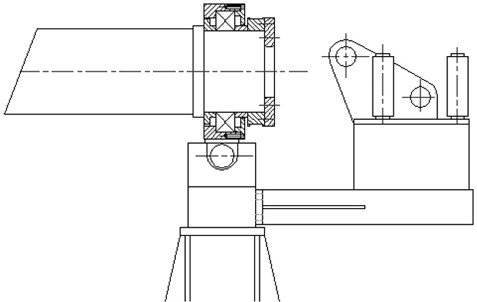

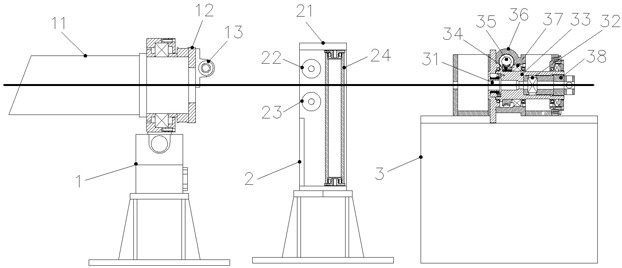

[0028] refer to Figure 3-6 , image 3 What is drawn is a structural schematic diagram of a wire drawing system used for steel wire drawing. As shown in the figure, the present invention relates to a wire drawing system for steel wire drawing, which includes a wire drawing machine, a pay-off frame 1, a guide roller frame 2 and a rotating wire drawing device 3 arranged in sequence.

[0029] The pay-off rack 1 includes a support and a pay-off channel 11 arranged on the support, one end of the pay-off channel 11 is connected to the wire drawing machine, and the port at the other end is provided with a bearing cover plate 12; one part of the bearing cover plate 12 One side is the pay-off channel 11, and the other side is provided with a pay-off roller 13, and the pay-off roller 13 is close to the bearing cover plate 12, is arranged on the top of the steel wire outlet, is fixed on the machine base or on the bearing cover plate 12, and The centerline of the pay-off roller 13 is pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com