Automatic assembly template for pouring concrete member

A technology for pouring concrete and automatic assembly, which is applied to molds, ceramic forming cores, ceramic forming mandrels, etc., can solve the problems of automation of formwork assembly, tight reconstruction time, heavy tasks, etc., and achieves good overall structural performance and production cycle. Short, material cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

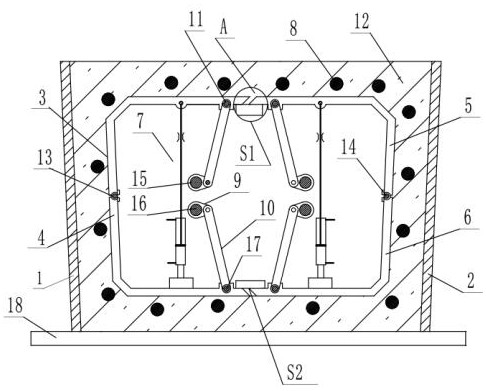

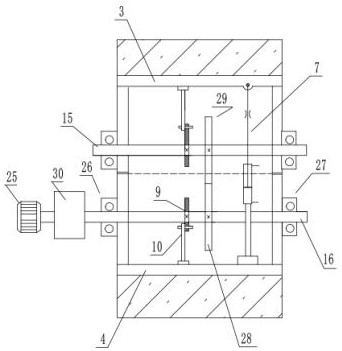

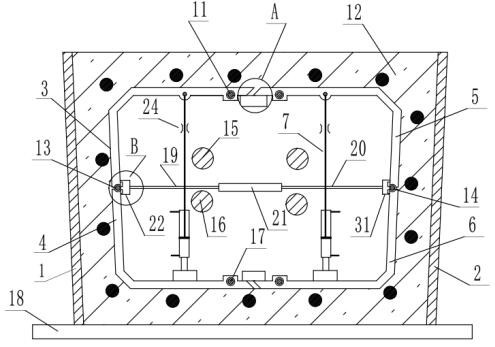

[0027] The invention provides an automatic assembly formwork for pouring concrete components, which is used to solve the problems of complex internal mold structure, time-consuming and labor-intensive disassembly and assembly and waste of materials in the production process of concrete components. It is mainly composed of outer formwork, inner formwork and support system of inner formwork.

[0028] The automatic assembly template includes an outer mold and an inner mold. The outer mold is composed of a left outer template 1 and a right outer template 2; Right lower formwork 6, the structure of four formworks is identical, taking the upper left formwork as example, the shape of described upper left formwork 3 is angular, and the two limits that form angular are vertical beam and horizontal beam, described left lower formwork 4, right upper formwork 5 and the lower right formwork 6 have the same shape and structure as the upper left formwork 3; the vertical beam of the upper lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com