Resin thermal transfer ribbon for soft label printing and preparation method thereof

A resin carbon, soft label technology, applied in printing, ink ribbons, and devices for coating liquid on surfaces, etc., can solve the problems of high printing plate making costs, increased printing costs, exhaust gas pollution, etc., achieve good scratch resistance, improve The effect of abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

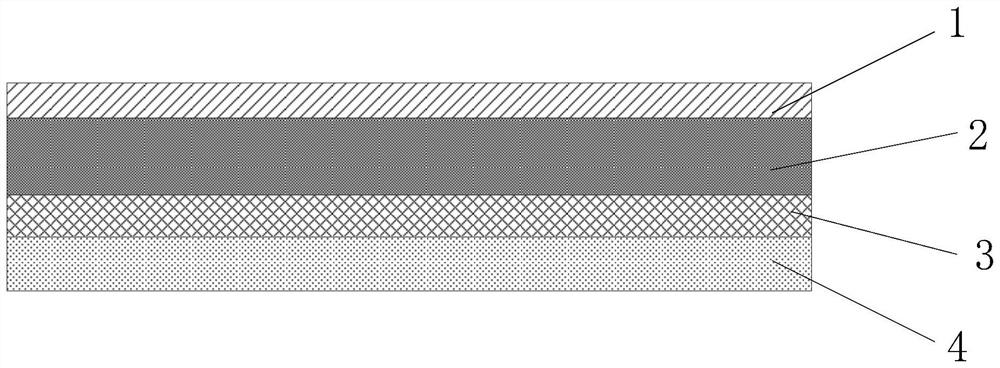

[0047] The preparation method of the resin ribbon for soft label printing of the present invention comprises the following steps:

[0048] 1) Prepare the solutions of the protective layer 3, the pigment layer 4, and the backcoat layer 1 respectively.

[0049] The solution preparation method of the back coat 1 is to dissolve 5 to 15 parts of polyamideimide in a mixed solvent of 100 parts of 2-butanone and 100 parts of toluene, and then add 2 to 6 parts of zinc stearate, 1 to 4 parts of Mix PE wax, 1-2 parts of leveling agent, 1-2 parts of dispersant, and 1-2 parts of antistatic agent.

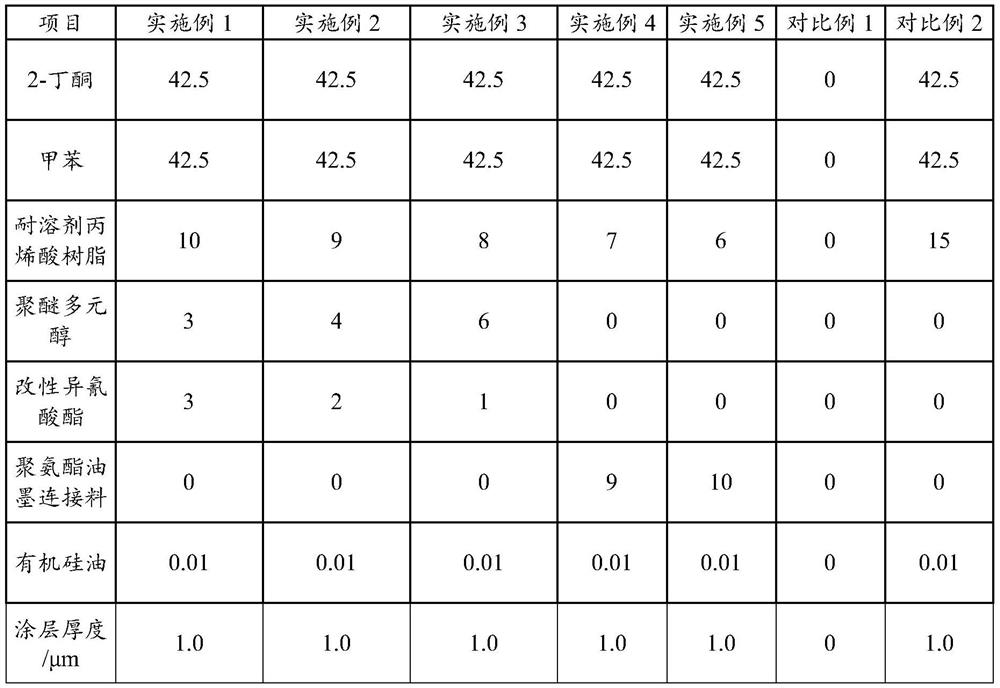

[0050] The solution preparation method of the protective layer 3 is as follows: 5-10 parts of solvent-resistant acrylic resin, 3-6 parts of polyether polyol and 1-3 parts of modified isocyanate or 8-15 parts of polyurethane ink binder, 0.01 part of organic silicone oil with 42.5 A mixed solvent of 2-butanone and 42.5 parts of toluene was dissolved.

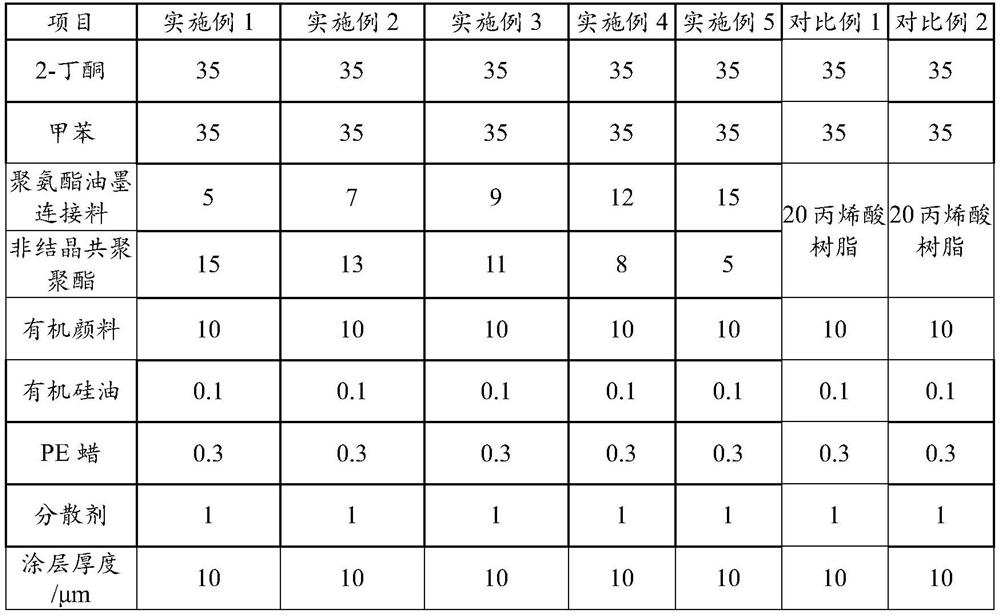

[0051] The solution preparation method of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com