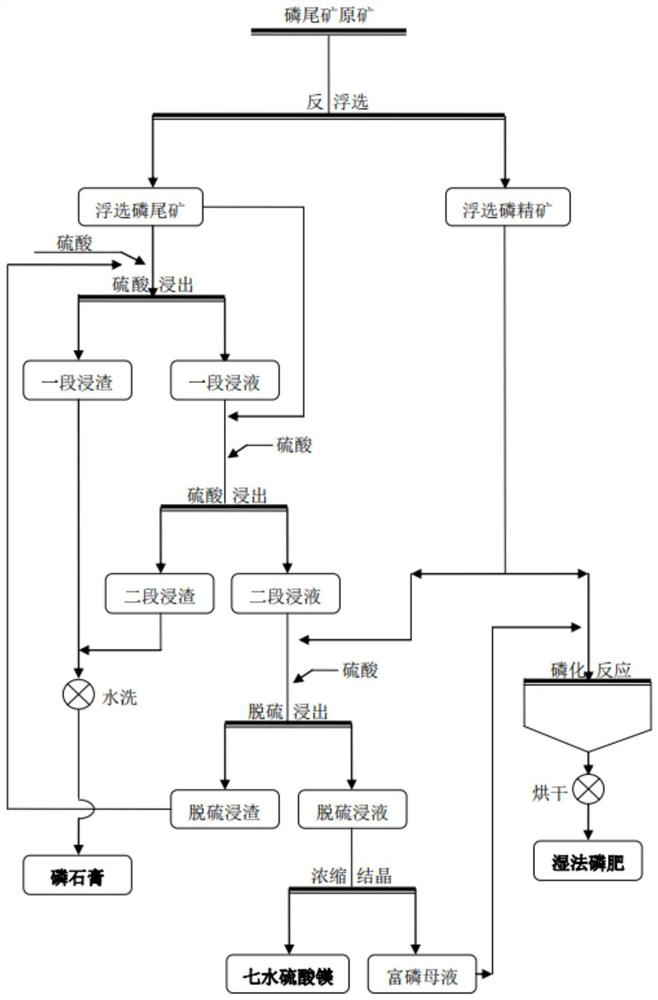

Method for large-scale absorption and high-value utilization of phosphate rock tailings

A technology for phosphate rock tailings and high value, applied in phosphate fertilizer, application, superphosphate and other directions, can solve the problems of difficult control and complex process, and achieve the effect of reducing serious impact, economical and reasonable, and reducing land resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] with P 2 o 5 Grade 10.63%, CaO grade 35.06%, MgO grade 15.10%, a certain calcium-magnesium type phosphorus tailings in Mabian, Sichuan as raw materials, using the process technology of the present invention, the following steps are carried out:

[0038] (1) Flotation: Add phosphate rock tailings to the flotation equipment for flotation operation, add 4kg / t sulfuric acid as inhibitor, 0.6kg / t sodium hexametaphosphate as dispersant, 0.1kg / t WF-1# (Wengfu 1#) was used as a collector to carry out reverse flotation open-circuit operation to obtain flotation phosphorus concentrate and flotation phosphorus tailings;

[0039] (2) Acid leaching: the flotation phosphorus tailings obtained by flotation operations are heated and mechanically stirred in dilute sulfuric acid under normal pressure for leaching, the solid-liquid weight ratio is 1:3, the weight ratio of 97% concentrated sulfate ore is 1.0, and the leaching temperature 70°C, leaching time 1.5 hours. This operation res...

Embodiment 2

[0046] with P 2 o 5 A calcium-magnesium-type phosphorus tailings in Mabian, Sichuan Province with a grade of 9.56%, a grade of CaO of 37.84%, and a grade of MgO of 17.23% is used as a raw material, and the process technology of the present invention is used to carry out the following steps:

[0047] (1) Flotation: Add phosphate rock tailings to the flotation equipment for flotation operation, add 3.5kg / t sulfuric acid as inhibitor, 0.5kg / t sodium hexametaphosphate as dispersant, 0.05kg / t WF-1 #As a collector, carry out reverse flotation open-circuit operation to obtain flotation phosphorus concentrate and flotation phosphorus tailings;

[0048] (2) Acid leaching: the flotation phosphorus tailings obtained by flotation operations are heated and mechanically stirred in dilute sulfuric acid under normal pressure for leaching, the solid-liquid weight ratio is 1:2, the weight ratio of 97% concentrated sulfate ore is 1.1, and the leaching temperature 75°C, leaching time 1.0 hour. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com