A kind of method for preparing ceramic raw material by sawing mudstone powder from granite stone

A technology for ceramic raw materials and sawing mud stone powder, which is applied in the direction of solid separation, etc., can solve the problems of high TFe content and low yield of ceramic products, and achieves the effects of reducing production cost, improving yield and short process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

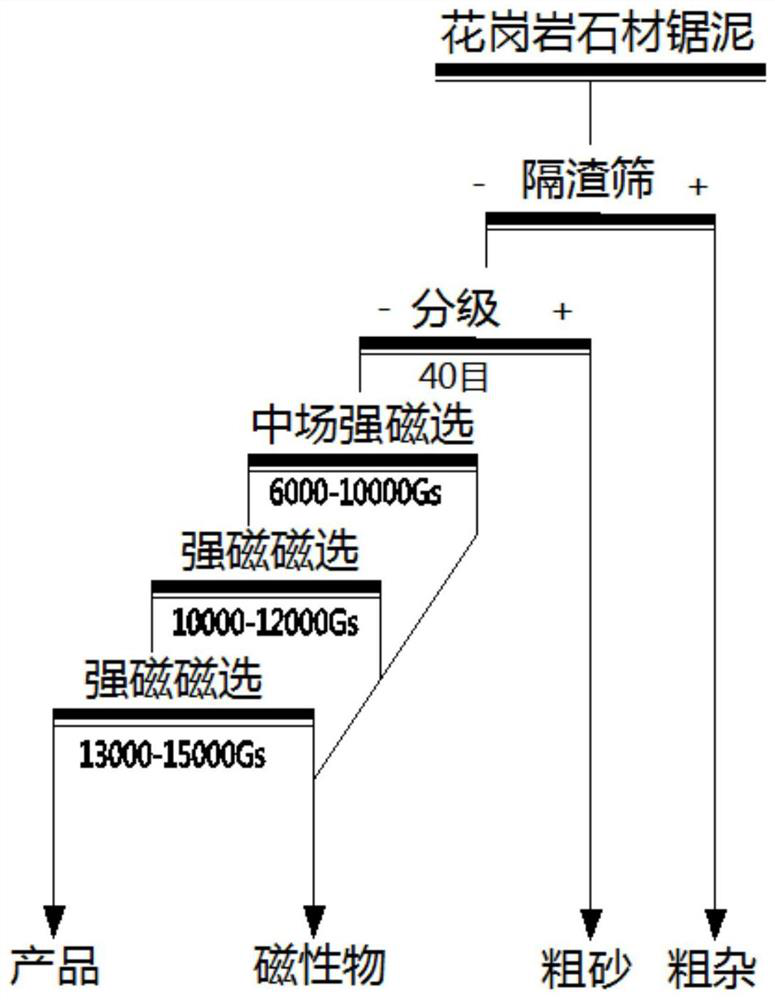

[0031] Taking the solid waste sawing mud of sesame white granite in a certain place in Henan Province as the test object, the test product was tested by Foshan Ceramic Research Institute Testing Co., Ltd. 2 0: 3.18-4.06%, Na 2 0: 5.26-6.06%, Fe 2 0 3 : 2.15-2.83%, Al 2 o 3 : 16.26-18.38%, SiO 2 : 65.77-72.60%, TiO 2 : 0.12-0.44%, CaO: 2.07-2.77%, MgO: 0.09-0.65%, product particle size -0.031mm (500 mesh) > 48%, raw ore 1200 °C firing whiteness is 6.5-8.6%, the preparation of ceramic raw materials Process flow chart such as figure 2 shown.

[0032] (1) Slag separation: First, add water to the granite stone sawing mud and stone powder to make granite stone sawing mud, and then pass through the slag separation sieve to remove coarse impurities in the granite stone sawing mud to obtain primary ore pulp; coarse impurities mainly include stone solid waste processing , Large-grained waste rocks, foreign matter, vegetation and other impurities introduced during storage and tran...

Embodiment 2

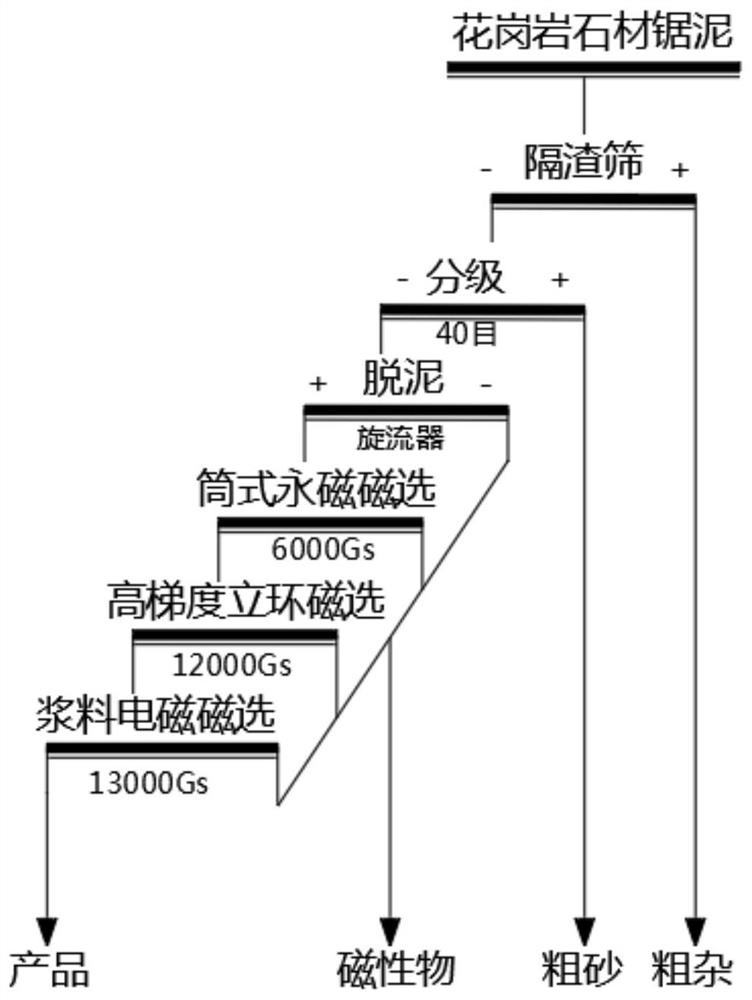

[0037] This embodiment is basically the same as Embodiment 1, the difference is: as image 3 As shown, the graded pulp enters the pump pool of the slurry pump, and is sent to the cyclone by the slurry pump for desliming treatment, and then the magnetic separation and impurity removal in step (3) are performed.

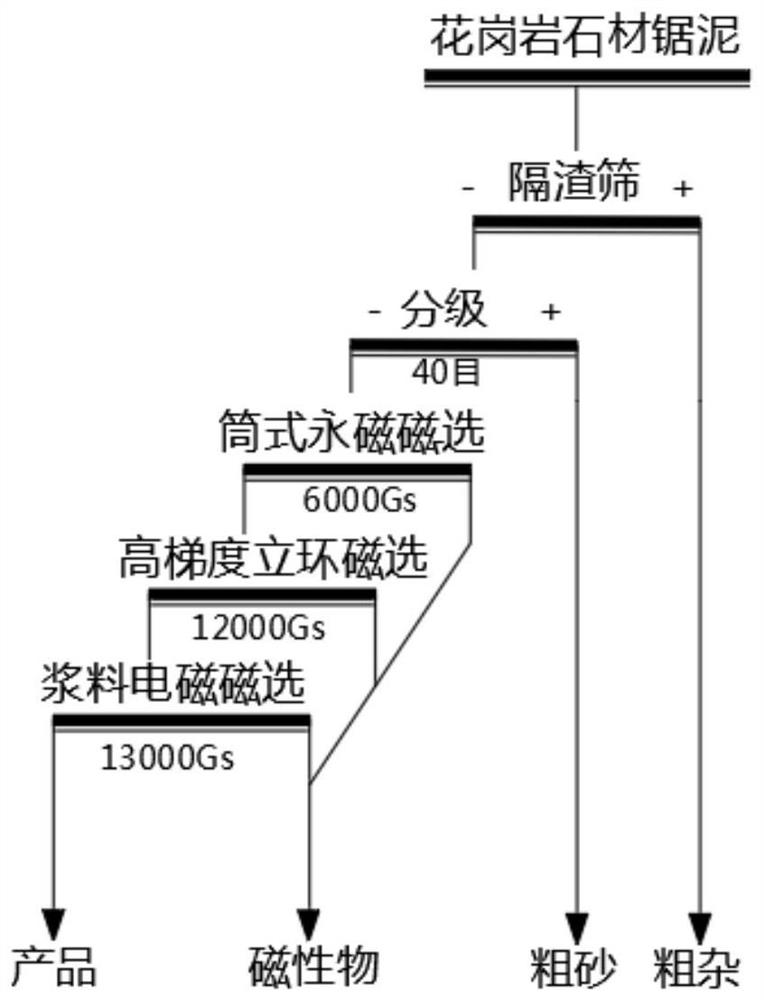

[0038] Taking granite solid waste sawing sludge in a certain place in Henan Province as the test object, the test product was tested by Foshan Ceramic Research Institute Testing Co., Ltd. 2 0: 3.84%, Na 2 0: 4.69%, Fe 2 0 3 : 1.54%, Al 2 o 3 : 13.84%, SiO 2 : 75.47%, TiO 2 : 0.071%, CaO: 1.4%, MgO: 0.18%, the whiteness of raw ore fired at 1200°C is 6.8%, the process flow chart for preparing ceramic raw materials is as follows figure 2 shown.

[0039] (1) Slag separation: First, add water to the granite stone sawing mud and stone powder to make granite stone sawing mud, and then pass through the slag separation sieve to remove coarse impurities in the granite s...

Embodiment 3

[0044] This embodiment is basically the same as embodiment one or two, the difference is: as Figure 4 As shown, in step (3), the equipment used for the three-stage magnetic separation and impurity removal of the classified pulp is used. The first stage magnetic separation adopts a plate permanent magnet magnetic separator with a field strength of 8000Gs, which mainly separates and removes mechanical iron and strong magnetic minerals. The second-stage magnetic separation adopts a high-gradient vertical ring magnetic separator with a field strength of 12000Gs, and the medium box adopts a network medium. The third-stage magnetic separation adopts a high-gradient vertical-ring strong magnetic separator with a field strength of 15000Gs. The non-magnetic material obtained last is a product; the magnetic material obtained after the three-stage magnetic separation is combined with the coarse sand obtained in step (2) and used as a building material dosage. Process flow chart such as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com