Dry quenching air introduction amount control method

A technology of air introduction and control method, which is applied in the direction of various fluid ratio control, coke oven, coke cooling, etc., can solve the problems of accuracy reduction, effective component reduction, burning coke powder, etc., so as to avoid lag and excess Effect of adjusting, reducing coke burning loss rate and avoiding coke burning loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to better understand the technical solution of the present invention, the technical solutions in the embodiments of the present invention will be apparent from the drawings in the embodiments of the present invention. Embodiments are merely embodiments of the invention, not all of the embodiments.

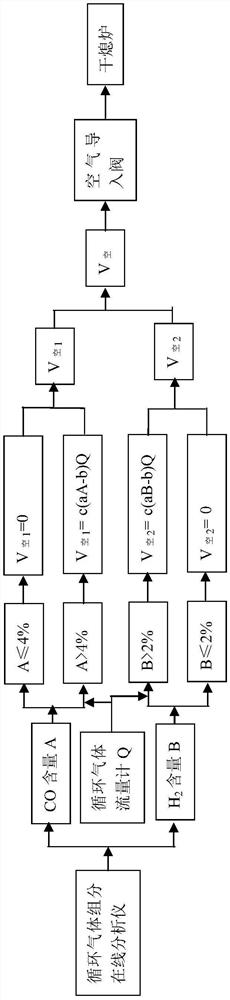

[0027] Combine figure 1 A dry-off air gas introduction control method, by circulating gas component online analyzer, the present invention adopts a dry extinguishing gas analyzer to obtain the following monitoring data: dry extinguishing circulating gas content A, dry quencher cycle Gas in the gas 2 The content B is obtained by the circulating gas flow meter to obtain the flow amount q of the dry-focused circulation gas; in the circulating gas content A, the dry extinguishing cycle gas 2 The content B is based on the flow Q of the dried coke circulating gas, and the required air introduction is calculated.

[0028] The content of CO in the dry quenching circulating gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com