CVD diamond heat conduction jumper wire and preparation process

A diamond and jumper technology, which is applied in the direction of cable/conductor manufacturing, conductive layer on insulating carrier, cooling/ventilation/heating transformation, etc., can solve the problems of huge influence of heat conduction design and great difficulty of shared heat dissipation, and achieve low thermal resistance , high practical value and promotion value, and the effect of increasing solderability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

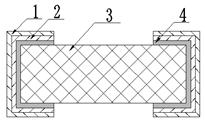

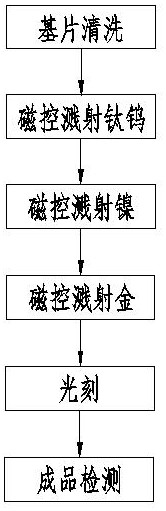

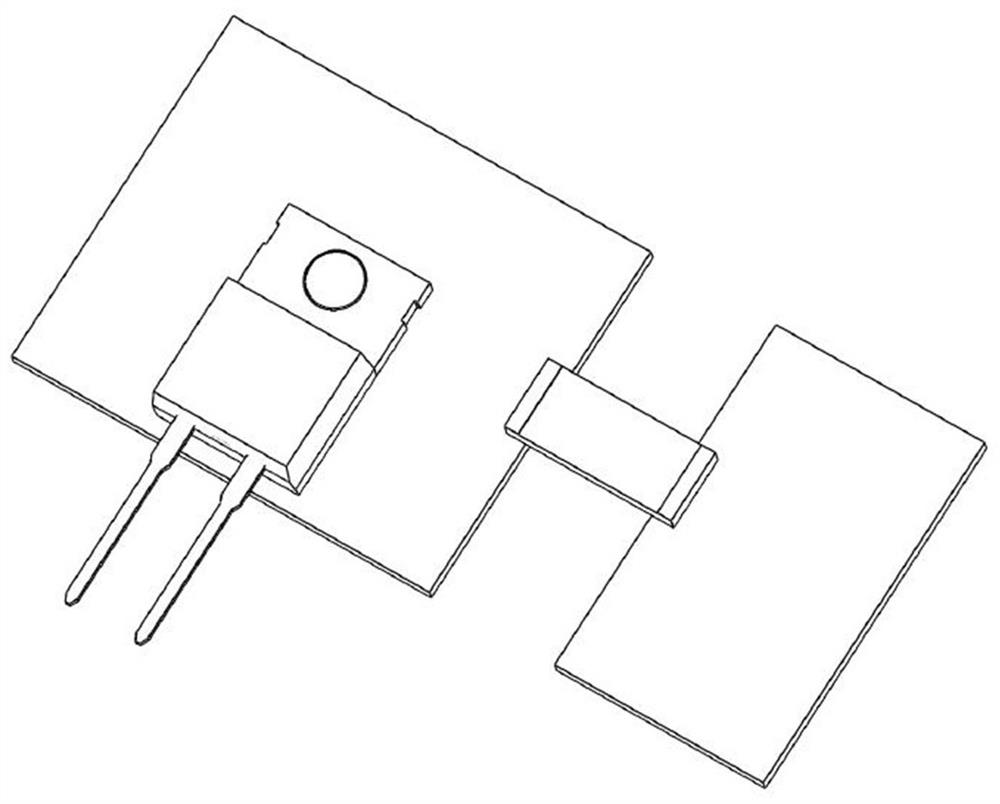

[0033] like Figure 1 to Figure 5 As shown, the present embodiment provides a CVD diamond heat-conducting jumper and its preparation process, and the heat-conducting jumper is connected between an electronic component and a heat sink. It should be noted that the serial numbers such as "first" and "second" in this embodiment are only used to distinguish similar components, and should not be understood as specific limitations on the scope of protection.

[0034] In this embodiment, the thermally conductive jumper includes a CVD diamond substrate 3, a titanium-tungsten layer 4, a nickel layer 2, and a gold layer 1 arranged sequentially from the inside to the outside. The CVD diamond substrate has an ultra-high thermal conductivity ≥ 1000 W / (m•K). Based on this advantage, it can make it a high-speed heat conduction channel, and the thermal resistance of the heat conduction jumper completed by using this advantage does not exceed 5.8°C / W. Moreover, diamond has a relatively low r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com